The KPT4805-60-S8 ORP sensor has a core made of a platinum silver chloride composite structure. It also has a design that doesn’t need maintenance and interfaces that are recognized around the world. This means that precise monitoring of oxidation-reduction potential (ORP) has less of an effect on chromium ion reduction efficiency and effluent compliance rate in situations like making circuit boards and treating wastewater that contains chromium. Specifically made to keep an eye on wastewater that contains chromium and has high corrosion resistance and strict standards. It provides consistent and reliable potential data assistance for process control.

★★★★★

Features

Specifications

| Parameter | Value |

|---|---|

| ORP Range | -1999—1999mv |

| Temperature Range | 0-60℃ |

| Pressure Range | 0-0.3 M Pa |

| Electric Potential | 245-270mv |

| Stability | ±8mv/24h |

Core product advantages

- In special cases, the correct answer is The ORP measurement range of -1999~1999mV can correctly catch oxidation-reduction reactions in wastewater that contains chromium. This is perfect for monitoring both circuit boards and wastewater. This is possible with a composite platinum indicator electrode and silver chloride reference sensor.

- Cost-effective and easy to take care of: Platinum plates don’t need any electrolytes, but they do need to be cleaned and calibrated every day. They lower the cost of staff and supplies for online tracking that happens often.

- Works with most systems: Because of the S8 socket and PG13.5 standard thread, foreign sensors can be switched out directly without the use of adapters. This makes it easier to update and replace imported monitoring equipment.

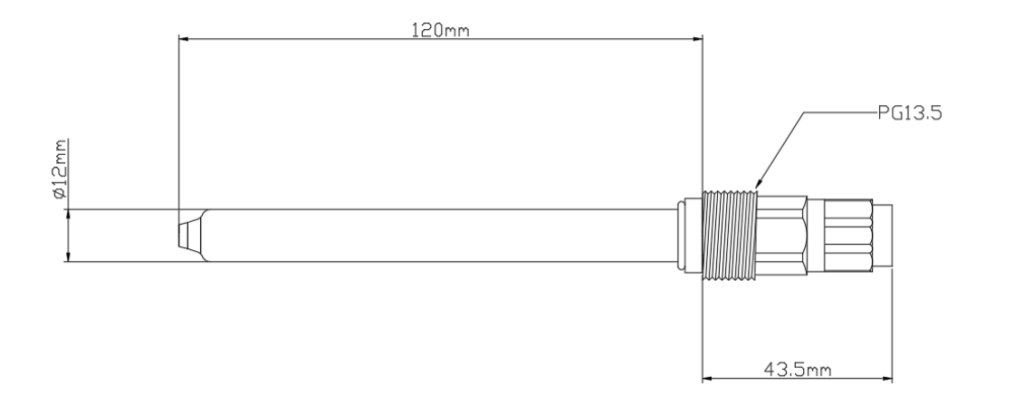

- The ability to meet a variety of needs: Sensors with lengths of 120, 150, 200, 250, and 300 mm are provided and can be set according to the depth of the wastewater and reaction tank. This way, the testing part and the liquid network portion are both submerged in the tested liquid at the same time, which ensures that detection is effective.

Accurately adapting to the scene

- Monitoring PCB wastewater treatment: As PCB production goes on, ORP is watched in real time in wastewater that has heavy metals and chromium. This gives exact information about the redox status of the wastewater, helps control how many chemicals are used, makes sure that heavy metal ions (especially chromium ions) are efficiently reduced and precipitated, and makes sure that the wastewater treatment is effective.

- Wastewater that has chromium in it needs to be handled differently. Possible finding in the process of treating wastewater that contains industrial chromium, like wastewater from electroplating chromium and liquid waste from chemicals that contain chromium, covering important steps like reduction and precipitation. The data can immediately be used to set runoff rules that will keep ORP abnormalities from releasing too many chromium ions.

Configuration of ORP standard solution

Pour 50ml of pH 4.00 standard buffer into a small beaker, add an appropriate amount of quinone hydroquinone reagent and stir until saturated. ORP standard solution should not be used for a long time after preparation to avoid failure.

Usage and Maintenance Guide

- When measuring, the sensor testing part and the reference liquid network component must be submerged in the measured liquid at the same time. If they are not, the detecting circuit will not work properly and the results will be wrong.

- You need to make the ORP standard solution (quinone hydroquinone saturated solution) and utilize it right away. You can’t store it for more than 48 hours after making it. If it goes beyond the time restriction, it will no longer be valid and the calibration will be less accurate.

- Cleaning a platinum plate: If it has oil on it, use cotton dipped in acetone or alcohol to gently wipe it. If the platinum plate is dirty with biological stuff that won’t dissolve, wipe it with 30–50% hydrochloric acid. Don’t use hard items to scrape it, though, because that could make it less sensitive to detection.

- When the sensor isn’t in use, it should be stored correctly so that it doesn’t stay in the air for too long or get wet in non-specialized soaking solutions. To keep the platinum plate from rusting or getting dirty, it is best to put a protective cover on it.

Sensor diagram illustration

- After opening the packaging, check whether there is mechanical damage to the sensitive bulb and electrode body of the sensor;

- Select the corresponding sensor sleeve or cable head for installation according to different electrodes;

- The connection between the sensor wire and the sensor is not waterproof, please make sure to do a good job of waterproofing.

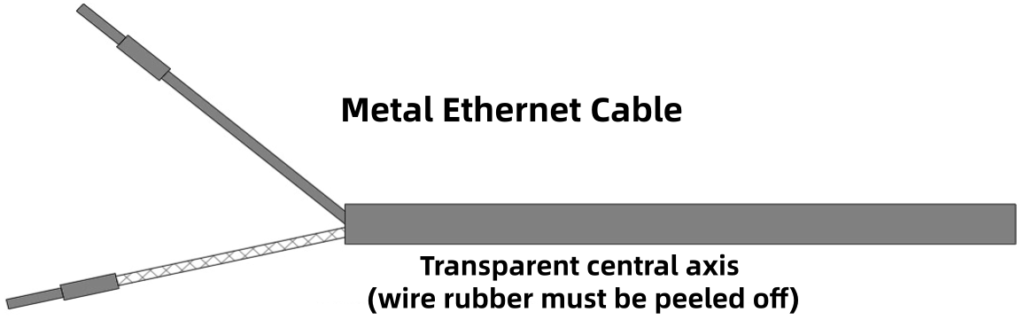

Wire stripping instructions

Attention

- The outer layer of the transparent central axis is covered with a conductive rubber layer and a metal mesh layer. When stripping, first strip the metal mesh layer into the metal mesh as shown in the picture, and be sure to removal of conductive black skin on the transparent central axis;

- The cable extends to the host without any contact points except for a dedicated junction box.

Technical Support

5 Best carbon monoxide detector for garage

10 Best carbon monoxide monitor for industrial use 2025

7+ Best Recommended Carbon Monoxide Detector for Industrial Use

What Is pH in Water? A Complete Guide to Understanding (2026)

6 Types of Industrial Oxygen Sensors

6 Best Industrial Gas Detector Manufacturers in the World

KPT4805-60-S8 ORP electrode is an exclusive monitoring device for the treatment of chromium containing wastewater on circuit boards. With its core advantages of precise response, maintenance free, and high compatibility, it perfectly adapts to the monitoring needs of strong corrosion and high requirements. Following standardized installation, cleaning, and calibration procedures can ensure accurate and reliable data while extending the service life of electrodes, providing continuous and stable technical support for the standard treatment of chromium containing wastewater.

Request a Quote

.png)