Confined space entry requires proper gas detection equipment and training. This guide provides information about available equipment, but proper confined space procedures, training, and compliance with OSHA 29 CFR 1910.146 and other local regulations are mandatory for safety. Always consult with qualified safety professionals before entering any confined space.

Table of Contents

- 1. Introduction to Confined Space Gas Detection

- 2. Selection Criteria for Portable Gas Detectors

- 3. Top 8 Portable Gas Detectors for Confined Spaces

- 4. Comparative Analysis & Specifications Table

- 5. Industrial Applications & Best Practices

- 6. Regulatory Compliance & Standards

- 7. Frequently Asked Questions

- 8. Conclusion & Recommendations

- 9. References & Standards

1. Introduction to Confined Space Gas Detection

The selection of a reliable portable gas detector for confined space operations is a critical safety decision that can mean the difference between life and death. Confined spaces—defined by OSHA as spaces large enough for employees to enter, with limited means of entry/exit, and not designed for continuous occupancy—present unique atmospheric hazards that require specialized monitoring equipment.

A quality portable gas detector for confined space entry must detect the “big four” atmospheric hazards: oxygen deficiency (below 19.5%), oxygen enrichment (above 23.5%), flammable gases (above 10% LEL), and toxic gases (CO, H2S). Modern detectors like those from Sino-Inst offer advanced features including wireless connectivity, multi-gas capabilities, and rugged designs suitable for harsh industrial environments.

“In confined space operations, your gas detector is your first line of defense against invisible, odorless killers. Choosing the right equipment and maintaining it properly isn’t just regulatory compliance—it’s fundamental to workplace safety.”

2. Selection Criteria for Portable Gas Detectors

2.1 Essential Features for Confined Space Applications

When selecting a portable gas detector for confined space use, consider these critical factors:

2.2 Sensor Technology Considerations

Different detection technologies serve specific purposes in confined space monitoring:

- Electrochemical Sensors: For toxic gases (CO, H2S, SO2) – specific, accurate, but have limited lifespan

- Catalytic Bead (Pellistor): For flammable gases – detects LEL but can be poisoned by silicones

- Infrared (IR) Sensors: For flammable gases and CO2 – not poisoned, more expensive but longer-lasting

- PID (Photoionization): For VOCs and toxic organic compounds – detects low concentrations

- MOS (Metal Oxide Semiconductor): For general toxic gas detection – sensitive but less specific

3. Top 8 Portable Gas Detectors for Confined Spaces

Based on performance, reliability, industry adoption, and feature sets, here are the top 8 portable gas detectors for confined space applications in 2025:

3.1 Sino-Inst Portable VOC Gas Detector

The Sino-Inst Portable VOC Gas Detector represents advanced volatile organic compound detection technology, specifically designed for environments where organic vapors present significant hazards in confined spaces.

Key Specifications

| Parameter | Specification |

|---|---|

| Detected Gas | VOCs (parameters can be customized, and other gases can also be customized); Optional: Can detect the concentration and temperature/humidity of any 1-4 gases |

| Range and Resolution | VOC: 0-100ppm, 0.01ppm (electrochemical) or 0-100%LEL, 0.1%LEL (catalytic combustion) or 0-10ppm, 0.01ppm (PID photoionization) |

| Detection Method | Diffusion-type measurement, with optional sampling handle (external handheld sampling pump) |

| Display | 2.31-inch 320*240 high-definition color screen display, 4-button operation |

| Detection Accuracy | ≤±3%F.S (Higher accuracy can be customized) |

| Alarm Method | Audible and visual alarm, vibration alarm, visual alarm, audible and visual alarm + vibration + visual alarm |

| Response Time | T90≤30 seconds |

| Operating Environment | Temperature: -40℃~+70℃; Relative humidity: ≤0-99%RH |

| Explosion-proof Type | Intrinsically safe ExiaⅡCT4Ga (CnEx16.3092) |

| Protection Rating | IP65, dustproof and splashproof |

| Dimensions & Weight | 130×68×34mm, 200g |

| Battery | 3.7VDC, 2100mA high-capacity rechargeable polymer battery with protection circuits |

Applications

This versatile portable gas detector for confined space applications is particularly suitable for:

- Chemical Processing: Monitoring VOC levels in tanks, reactors, and storage vessels

- Painting & Coating Operations: Confined spaces with solvent vapors and paint fumes

- Waste Treatment: Sewage treatment plants, landfills, and composting facilities

- Petrochemical: Refinery operations, pipeline maintenance, and tank entry

- Manufacturing: Semiconductor industry, electronics manufacturing with solvent use

Compliance Note: The Sino-Inst VOC detector meets intrinsically safe standards for use in hazardous locations and provides the necessary detection capabilities for OSHA-confined space entry requirements involving organic vapors.

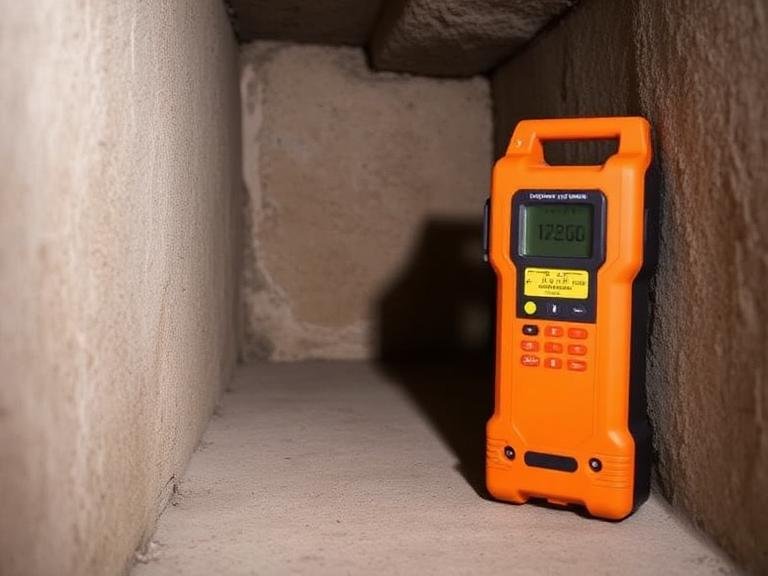

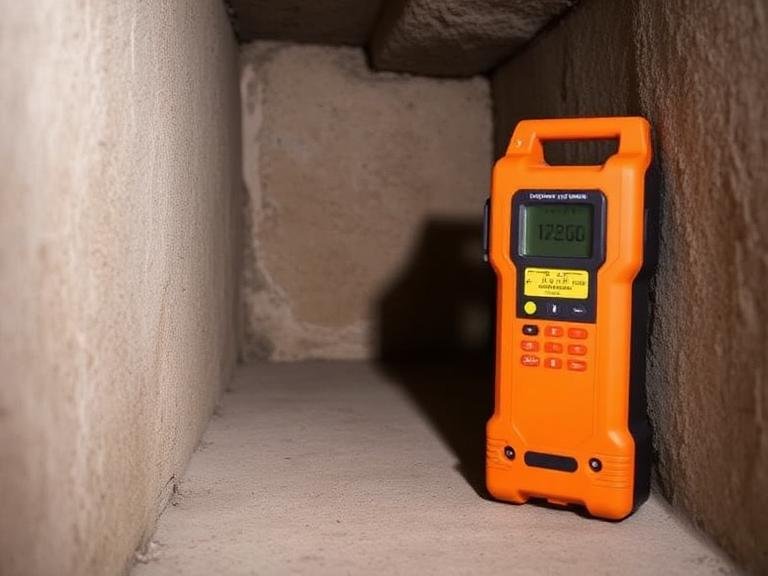

3.2 Sino-Inst Handheld Multi Gas Detector-Wireless

The Sino-Inst Handheld Multi Gas Detector-Wireless represents the next generation of confined space monitoring with integrated wireless communication capabilities for real-time data transmission and remote monitoring.

Key Specifications

| Parameter | Specification |

|---|---|

| Measuring Gas | Combustible gas, oxygen, carbon monoxide, hydrogen sulfide, etc. |

| Range Selection | Combustible: 0-100%LEL; Oxygen: 0-30%VOL; CO: 0-500PPM; H2S: 0-100PPM |

| Sampling Accuracy | ±2%F.S |

| Working Temperature | -30℃ to 50℃ |

| Protection Level | IP66 waterproof splash and short-term rain |

| Receiving Device | User computer, mobile phone, web page, control alarm, PLC, DCS, DDC, etc. |

| Alarm Method | On-site sound and light alarm, external alarm, remote controller alarm, computer data acquisition software alarm |

| Output Signal | GPRS, 4G, WIFI, LORA, ZigBee wireless signals (camera optional) |

| Transmission Distance | GPRS/4G/WIFI: no distance limit; LORA: 2-5Km in towns, up to 20Km in suburbs |

| Battery | Rechargeable lithium battery 2800mAh (24V); >16 hours single gas, >12 hours four-in-one |

| Detection Principle | Electrochemical, catalytic combustion |

| Response Time | T90<10S |

| Explosion-proof Level | ExdIICT6 |

| Dimensions | 460mm × 340mm × 115mm |

Advanced Features & Applications

- Real-Time Remote Monitoring: Wireless transmission allows safety supervisors to monitor atmospheric conditions from a safe location

- SMS Alert System: Automatic text message notifications for alarm conditions

- Multi-Platform Compatibility: Data accessible via computer, smartphone, or web interface

- Extended Range Communications: LORA technology enables monitoring in remote locations without cellular coverage

- Integrated Data Logging: Comprehensive recording for compliance and incident analysis

This portable gas detector for confined space applications is particularly valuable for:

- Remote Confined Space Entry: Where entry and exit points are far from command stations

- Team Monitoring: Multiple detectors can be monitored simultaneously from a single location

- Hazardous Material Response: Quick deployment with immediate remote monitoring capability

- Industrial Maintenance: Turnaround operations in refineries and chemical plants

3.3 Additional Top-Performing Gas Detectors

3.3.1 Industrial Scientific Ventis Pro5 Multi-Gas Detector

With LENS Wireless technology that enables real-time gas readings and man-down alarms to be shared among team members. Features durable construction, long battery life, and configurable for up to 5 gases including PID for VOC detection.

3.3.2 MSA Altair 5X Multi-Gas Detector

Rugged, reliable multi-gas detector with MotionAlert and InstantAlert features. XCell sensors provide extended life with reduced calibration frequency. IP67 rated with 24+ hour battery life.

3.3.3 RKI Instruments GX-3R Pro Multi-Gas Monitor

Compact, lightweight design with simple one-button operation. Includes standard LEL, O2, CO, and H2S sensors with optional fifth sensor capability. Excellent for basic confined space entry requirements.

3.3.4 Honeywell BW Solo Gas Detector

Simple, single-gas detectors available for various gases. Affordable option for supplemental monitoring or specific gas threats. Compact design with easy one-button operation.

3.3.5 Dräger X-am 8000 Multi-Gas Detector

Advanced multi-gas detector with up to 7 sensors including IR for flammable gases and PID for VOC detection. Smart calibration system and extensive data logging capabilities.

3.3.6 Scott Instruments Tango TX1

Intrinsically safe, compact multi-gas detector with Bluetooth connectivity. Features include man-down alarm, remote monitoring capability, and long sensor life with automatic bump test reminder.

4. Comparative Analysis & Specifications Table

| Model | Max Sensors | Wireless | Battery Life | Protection Rating | Explosion Proof | Key Features |

|---|---|---|---|---|---|---|

| Sino-Inst Portable VOC | 4 | Optional | 12+ hours | IP65 | ExiaⅡCT4Ga | PID VOC detection, -40°C operation |

| Sino-Inst Wireless Multi | 4+ | Yes (4G/WIFI/LORA) | 12-16 hours | IP66 | ExdIICT6 | Real-time remote monitoring, SMS alerts |

| Industrial Scientific Ventis Pro5 | 5 | Yes (LENS Wireless) | 18+ hours | IP67 | IS/ATEX | Team monitoring, man-down detection |

| MSA Altair 5X | 5 | Optional | 24+ hours | IP67 | IS/ATEX | XCell sensors, MotionAlert |

| RKI GX-3R Pro | 5 | No | 18 hours | IP54 | IS | Simple operation, affordable |

| Honeywell BW Solo | 1 | No | 2+ years | IP66/67 | IS | Single gas, maintenance-free |

| Dräger X-am 8000 | 7 | Optional | 20+ hours | IP68 | ATEX/IECEx | IR/PID capable, smart calibration |

| Scott Tango TX1 | 4 | Yes (Bluetooth) | 14+ hours | IP66 | ATEX/IECEx | Compact, auto bump test reminder |

5. Industrial Applications & Best Practices

5.1 Industry-Specific Confined Space Applications

5.2 Best Practices for Confined Space Gas Detection

- Pre-Entry Testing: Test at all levels (top, middle, bottom) as gases stratify based on density

- Continuous Monitoring: Maintain monitoring throughout entry and work activities

- Proper Calibration: Bump test daily, calibrate according to manufacturer specifications

- Training: Ensure all users understand alarm responses and emergency procedures

- Maintenance: Regular inspection, cleaning, and sensor replacement as needed

- Documentation: Maintain records of tests, calibrations, and exposures

6. Regulatory Compliance & Standards

Key Regulatory Standards

- OSHA 29 CFR 1910.146: Permit-required confined spaces – requires testing before entry and as necessary

- OSHA 29 CFR 1910.134: Respiratory protection – may require supplied air if atmosphere is IDLH

- ANSI/ASSP Z117.1: Safety Requirements for Confined Spaces

- NFPA 350: Guide for Safe Confined Space Entry and Work

- ATEX Directive 2014/34/EU: Equipment for explosive atmospheres

- IECEx System: International certification for explosive atmospheres

- UL 913: Standard for intrinsically safe apparatus

7. Frequently Asked Questions

Calibration frequency depends on usage, environment, and manufacturer recommendations, but general guidelines include:

- Bump Testing: Daily before use to verify sensor and alarm functionality

- Full Calibration: Every 30-90 days, or after exposure to high gas concentrations

- Sensor Replacement: Electrochemical sensors typically last 1-3 years; catalytic bead sensors 2-4 years; IR sensors 5+ years

- Documentation: Maintain calibration records for compliance and troubleshooting

Always follow manufacturer recommendations and consider more frequent calibration in harsh environments or critical applications.

At minimum, a confined space gas detector should monitor the “big four”:

- Oxygen (O2): Deficiency (<19.5%) or enrichment (>23.5%)

- Combustible Gases: Lower Explosive Limit (LEL) – alarm at 10% LEL

- Carbon Monoxide (CO): Toxic gas from incomplete combustion

- Hydrogen Sulfide (H2S): Toxic gas common in wastewater and petroleum

Additional sensors may be needed based on specific hazards: VOCs, SO2, NO2, Cl2, NH3, or other process-specific gases.

Wireless gas detectors offer significant safety advantages:

- Remote Monitoring: Safety personnel can monitor atmospheric conditions from outside the confined space

- Real-Time Alerts: Immediate notification of changing conditions

- Team Safety: Multiple detectors can be monitored simultaneously

- Data Recording: Continuous logging for incident investigation and compliance

- Reduced Entry: Fewer personnel need to enter hazardous areas for monitoring

- Emergency Response: Quick assessment of conditions for rescue planning

While portable gas detectors are essential for most confined spaces, consider these limitations:

- Extreme Temperatures: Check operating range (Sino-Inst units work from -40°C to +70°C)

- High Humidity/Dust: Ensure adequate IP rating and consider filters

- Oxygen-Deficient Atmospheres: Some sensors require oxygen to function properly

- Chemical Interference: Certain chemicals can poison or damage sensors

- Radio Silence Areas: Wireless features may not function in shielded areas

Always conduct a hazard assessment specific to each confined space before entry.

Regular maintenance is critical for reliable operation:

- Daily: Visual inspection, bump test, battery check

- Weekly: Clean sensors and housing, check filters

- Monthly: Full calibration with certified test gas

- Quarterly: Complete functional test, software updates

- Annually: Professional servicing, sensor replacement if needed

- As Needed: After exposure to high gas concentrations, physical shock, or contaminants

Maintain detailed records of all maintenance activities for compliance and warranty purposes.

8. Conclusion & Recommendations

Selecting the right portable gas detector for confined space applications requires careful consideration of specific hazards, environmental conditions, regulatory requirements, and operational needs. The Sino-Inst detectors highlighted in this guide offer advanced features particularly suited for modern industrial applications, including VOC detection capabilities and wireless monitoring options.

Final Safety Recommendations

- Conduct Thorough Hazard Assessments: Identify all potential atmospheric hazards before selecting equipment

- Choose Multi-Gas Capability: Ensure detection of O2, LEL, CO, and H2S at minimum

- Consider Environmental Factors: Select appropriate protection ratings for temperature, humidity, and dust

- Prioritize Reliability: Choose reputable brands with proven track records in industrial applications

- Invest in Training: Proper use and interpretation are as important as equipment selection

- Implement Maintenance Programs: Regular calibration and testing ensure continued reliability

- Stay Current with Technology: Consider wireless and connected monitoring capabilities for enhanced safety

.png)