The GRT1120WE pH sensor, with its two-point ceramic core liquid interface anti blocking design, solution grounding anti-interference function, and low maintenance characteristics, solves the problem of electrode blockage caused by high viscosity suspensions, emulsions, proteins, and other media in complex monitoring scenarios such as sewage treatment, electroplating chromium removal, and chemical viscous liquids, as well as electrostatic interference in industrial environments that can affect data accuracy. Becoming the preferred equipment for online pH monitoring of complex media in multiple industries, providing stable and reliable data support for process regulation and environmental compliance.

★★★★★

Features

Specifications

| Parameter | Value |

|---|---|

| pH Range | 0-14 |

| Temperature Range | 0-60℃ |

| Pressure Range | 0-0.3 M Pa |

| Zero potential | 7±0.5 |

| Theoretical percentage slope | ≥ 95% |

| Thermistor | PT1000 (customizable: PT100/10K/PT1000/30K/2.252K) |

Core product advantages

- Anti blocking and anti fouling: two-point ceramic core+gel dielectric, suitable for high viscosity and high impurity media, not easy to block;

- Maintenance free: No need to replenish electrolyte, only need to clean and calibrate daily, with a small maintenance amount;

- Anti interference: solution grounding function, eliminating static electricity and noise, accurate data;

- High adaptability: PG13.5 universal thread+optional length+PVC/PP sheath, strong adaptability.

Accurately adapting to the scene

- Food processing industry: pH monitoring of protein/high viscosity materials such as starch paste, syrup, dairy products, etc., suitable for real-time control of production processes;

- In the field of biomedicine: pH detection of viscous systems such as fermentation broth and protein extracts to meet the requirements of high cleanliness and low interference monitoring;

- Environmental hazardous waste treatment: monitoring of hazardous waste leachate containing sludge and suspended solids, tolerant to complex impurities, and avoiding blockages;

- Fine chemical scene: pH control monitoring of dye slurry, pigment suspension, and viscous additives, adapted to strong interference production environments;

Usage and Maintenance Guide

- Before measurement, the sensor should be washed in distilled water or deionized water, and the water should be absorbed dry with filter paper to ensure that the sensor bulb and the liquid junction are immersed in the measured liquid at the same time, avoiding impurities from interfering with the detection.

- When the sensor is idle, it needs to be cleaned and put into a protective cover containing 3.3Mol/L KCL immersion solution to maintain the activity of the sensitive membrane. It is strictly prohibited to soak it in distilled water, protein solution or acidic chloride solution for a long time, and avoid contact with organic silicon oil.

- If the glass film appears semi transparent or deposited, it can be washed with dilute hydrochloric acid and rinsed clean with water; It is recommended to clean the sensors once a week and coordinate with the instrument to complete calibration to ensure detection accuracy.

- When the sensor cannot complete the calibration procedure after maintenance, it indicates that it has lost its responsiveness and needs to be replaced with a new one in a timely manner.

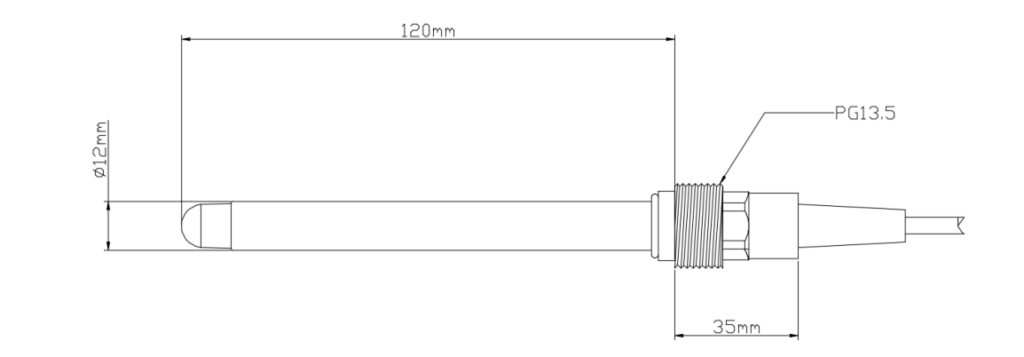

Sensor diagram illustration

- After opening the packaging, check whether there is mechanical damage to the sensitive bulb and electrode body of the electrode;

- Remove the sensor protective cover and check if there are any bubbles in the sensitive bulb of the sensor. If so, gently shake the electrode in a vertical plane to remove the bubbles;

- Select the corresponding sensor sleeve or cable head for installation according to different electrodes;

- The connection between the sensor wire and the sensor is not waterproof, please make sure to do a good job of waterproofing.

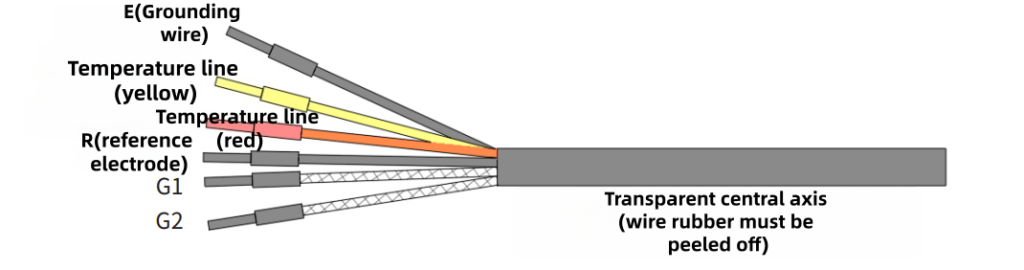

Wire stripping instructions

Attention

- The outer layer of the transparent central axis is covered with a conductive rubber layer and a metal mesh layer. When stripping, first strip the metal mesh layer into the metal mesh as shown in the picture, and be sure to removal of conductive black skin on the transparent central axis;

- The cable extends to the host without any contact points except for a dedicated junction box.

Technical Support

5 Best carbon monoxide detector for garage

10 Best carbon monoxide monitor for industrial use 2025

7+ Best Recommended Carbon Monoxide Detector for Industrial Use

What Is pH in Water? A Complete Guide to Understanding (2026)

6 Types of Industrial Oxygen Sensors

6 Best Industrial Gas Detector Manufacturers in the World

The GRT1120WE pH sensor is not an ordinary general-purpose electrode, but a professional equipment specially designed for the three major scenarios of “high viscosity, high impurities, and high interference”. From food processing and biomedicine to environmental hazardous waste and fine chemicals, it can become the “reassurance pill” for your monitoring work with stable and reliable performance, convenient and worry free maintenance. A standardized installation, wiring, and maintenance process can maximize its core advantages while extending its service life, providing continuous and accurate data support for your process optimization and environmental compliance.

Request a Quote

.png)