The commercial pH sensor GRT1020W was designed to find sewage online. Spherical PTFE antifouling liquid junction and solid gel insulator. It doesn’t become dirty or blocked and requires little maintenance. It can measure pH from 0 to 14 at 60°C and fit 3/4-inch threads. This means it can monitor pH levels in municipal and industrial sewage over time. It will provide accurate information to monitor and regulate the sewage treatment process and comply with environmental laws.

★★★★★

Features

Specifications

| Parameter | Value |

|---|---|

| Measurement Range | 0-14 pH |

| Theoretical percentage slope | ≥95% |

| Zero potential | 7±0.5 |

| Temperature Range | 0-60℃ |

| Pressure Range | 0-0.3 M Pa |

| Thread Size | 3/4 inch NPT |

Scope of Application

- Suitable for online detection of sewage.

Core advantages define industrial grade reliability

Pollution- and blockage-resistant, for complicated sewage media

Unlike standard liquid interfaces, its circular polytetrafluoroethylene liquid interface may filter suspended contaminants in sewage, preventing electrode response latency and data drift. Long-term online monitoring without disassembly or cleaning is possible in high turbidity and impurity municipal water inlets, industrial wastewater outputs, and other situations.

Low-maintenance, gel dielectric, anti-poisoning

The solid gel dielectric salt bridge reduces on-site maintenance and resists toxic ions like S ² ⁻ and CN ⁻, preventing electrode poisoning and scrapping, extending electrode service life. It is ideal for pH monitoring in high-risk wastewater, including chemical sulfur-containing cyanide wastewater and electroplating heavy metal wastewater.

Reliable and simple to setup

- Highly accurate measuring performance: glass sensitive film, low electrode resistance, quick response speed, theoretical slope > 95%, zero potential regulated at 7 ± 0.5, capturing minor pH variations in sewage.

- Installing standardly: With 3/4 inch NPT standard threads, it may easily fit the protective sleeves of existing sewage monitoring pipes and supports without structural modifications and be installed and utilized immediately;

- Compatible with many situations: With an operating temperature of 0-60 ℃ and pressure resistance of 0-0.3MPa, it can monitor municipal sewage plants, industrial park pipes, and small to medium-sized industrial wastewater treatment tanks.

Core application

Monitoring municipal sewage treatment

Problems: Municipal sewage includes pollutants and the biochemical tank contains sulfides. Traditional electrodes clog and poison, needing regular replacement and maintenance.

Solution:The GRT1020W antifouling liquid interface prevents contaminants from blocking the water input, and the gel dielectric prevents biochemical tank sulfide poisoning. It can be reliably monitored at the water input, aeration tank, sedimentation tank, water output, and other linkages for process adjustment and effluent acceptance.

Industrial park sewage pipeline monitoring

Pain points: The pipeline network’s sewage composition is complicated, the points are distributed, electrode installation and maintenance are challenging, and real-time warning of unlawful excessive acidity and alkalinity wastewater discharge is needed.

Solution: The electrode’s standardized thread may be rapidly put at pipeline network monitoring sites with minimum maintenance to decrease human inspection expenses. Real-time feedback on pipeline pH changes, locking in unlawful emissions, and pipeline network safety are possible with the quick reaction and excellent stability performance.

Keeping an eye on small and medium-sized industrial wastewater

Pain points: Electroplating and small-scale chemical businesses’ wastewater include cyanide and sulfur in it. Regular electrodes are easy to poison and break, and monitoring costs a lot. Solution: The anti-virus characteristic of gel dielectrics can make electrodes last longer and cost less to replace. At the same time, correct pH data may help businesses with their wastewater pretreatment process, make sure that the pH levels of the wastewater they release exceed environmental regulations, and prevent compliance concerns.

Installation and Maintenance Guide

Measurement operation specifications

- Before measurement, the sensor should be washed in distilled water or deionized water, and the surface moisture should be absorbed by filter paper to prevent impurities from contaminating the measured water sample; Ensure that the electrode bubbles and liquid network are immersed in the water sample simultaneously during measurement to avoid data deviation.

- The connection between the sensor wire and the electrode is not waterproof, and sealing and waterproof treatment should be done during installation to avoid sewage infiltration.

Daily maintenance and calibration

- Before you begin the process of taking measurements, you should clean the electrode by rinsing it with distilled water and then pat it dry using a piece of filter paper.

- In order to maintain a full protective cap, it is necessary to keep it filled with a 3.3mol/L solution of potassium chloride when it is not being used.

- Avoid leaving yourself in distilled water, protein solutions, or acidic chloride solutions for an extended period of time.

- Use a small amount of an acidic solution of hydrochloric to cleanse If you notice that the glass membrane has become foggy or has deposits on it, clean it with water.

- In order to ensure optimal functioning, the pH meter should be cleaned and calibrated on a weekly basis. When it comes to the consistent application of lime slurry, this is quite crucial.

- The sensor will be unable to regain its response if you are unable to carry out the calibration procedure on the sensor by employing the aforementioned procedures for maintenance and upkeep. Could you please buy a new sensor?

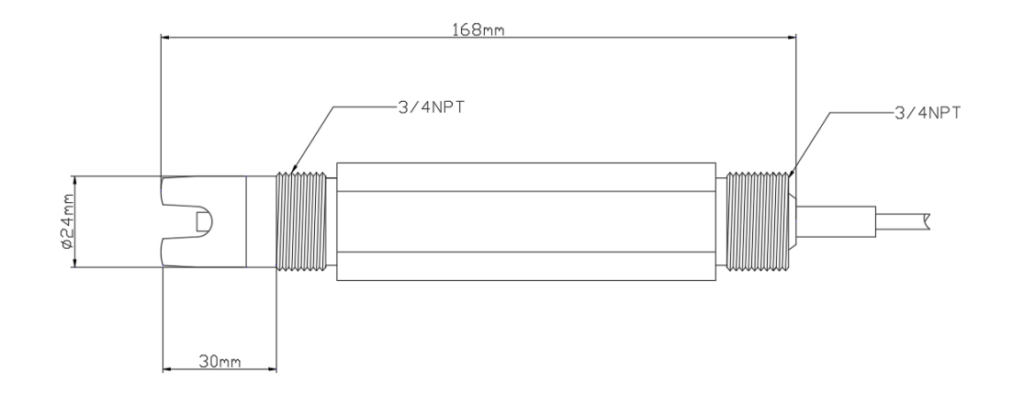

Sensor diagram illustration

- After opening the packaging, check whether there is mechanical damage to the sensitive bulb and electrode body of the electrode.

- Remove the sensor protective cover and check if there are any bubbles in the sensitive bulb of the electrode. If so, gently shake the sensor in a vertical plane to remove the bubbles.

- Select the corresponding sensor sleeve or cable head for installation according to different electrodes.

- The connection between the sensor wire and the electrode is not waterproof, please make sure to do a good job of waterproofing.

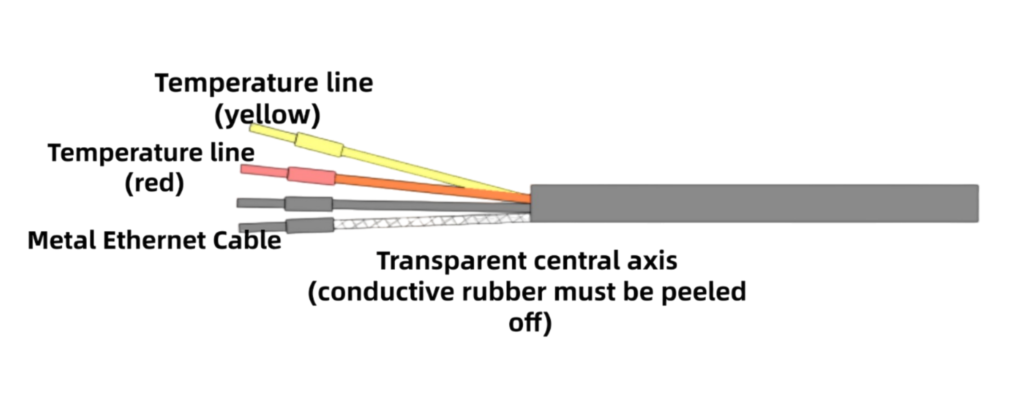

Wire stripping instructions

Attention

- The outer layer of the transparent central axis is covered with a conductive rubber layer and a metal mesh layer. When stripping, first strip the metal mesh layer into the metal mesh as shown in the picture, and be sure to removal of conductive black skin on the transparent central axis;

- The cable extends to the host without any contact points except for a dedicated junction box.

Technical Support

5 Best carbon monoxide detector for garage

10 Best carbon monoxide monitor for industrial use 2025

7+ Best Recommended Carbon Monoxide Detector for Industrial Use

What Is pH in Water? A Complete Guide to Understanding (2026)

6 Types of Industrial Oxygen Sensors

6 Best Industrial Gas Detector Manufacturers in the World

In the field of sewage monitoring, electrode blockage, poisoning and cumbersome maintenance are common pain points in the industry, while GRT1020W solves these problems from the root by virtue of three core capabilities of antifouling fluid interface, antitoxic gel dielectric and standardized installation, which not only reduces the operation and maintenance costs, but also ensures the accuracy of data.

Request a Quote

.png)