GRT1020P is an ORP electrode used for cleaning circuit boards and wastewater containing chromium. It has a platinum indicator electrode and a silver chloride reference electrode, which work together to reliably measure the entire redox potential range from -1999 to 1999 mV. It can operate at temperatures ranging from 0 to 60 ° C and features a 3/4 inch NPT standard thread mounting design. It is easy to install on site and has high measurement balance accuracy. It is an important tool for monitoring specific wastewater treatment processes.

★★★★★

Features

Specifications

| Parameter | Value |

|---|---|

| ORP Range | -1999—1999 mv |

| Stability | ±8 mv/24 h |

| Temperature Range | 0-60℃ |

| Pressure Range | 0-0.3 M Pa |

| Electric Potential | 245-270mv |

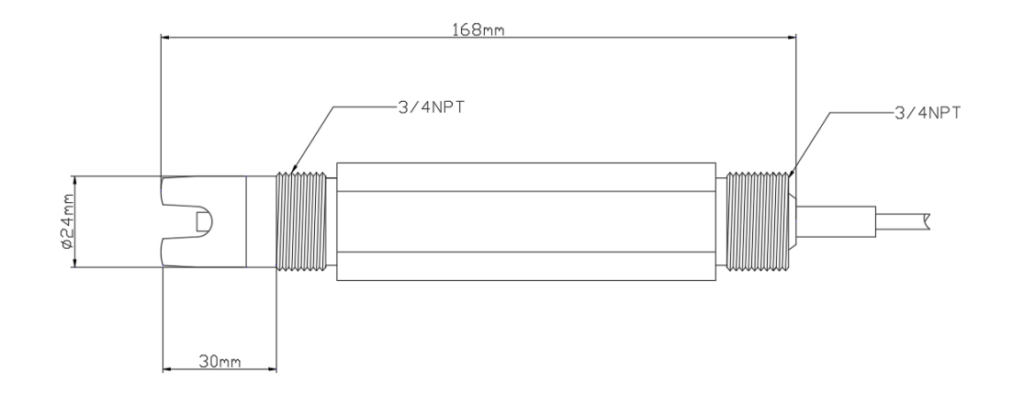

| Thread Size | 3/4 inch NPT |

Scope of Application

- Used for detecting the oxidation-reduction potential of circuit boards and chromium containing wastewater treatment.

Core advantages

Composite Electrode Architecture for Accurate and Stable Monitoring

The electrode integrates a platinum indicator electrode and a silver-silver chloride reference electrode into a single composite structure, allowing it to quickly sense changes in the redox potential of wastewater. Its 24-hour potential stability is controlled within ±8mV, and the potential reference value remains stable at 245-270mV. It can precisely capture subtle fluctuations in potential during the treatment of circuit board wastewater and chromium-containing wastewater, providing reliable data support for process adjustments.

Suitable for special working conditions, easy installation and maintenance

- Temperature and pressure resistance adaptation: Supports working temperatures of 0-60 ℃ and pressure resistance of 0-0.3MPa, which can meet the monitoring environment of conventional wastewater treatment tanks in the circuit board and electroplating industries;

- Standardized installation: Equipped with 3/4 inch NPT standard threads, it can directly match existing wastewater monitoring pipelines or brackets without the need for additional structural modifications;

- Targeted cleaning: When platinum plates are contaminated with oil or organic matter, they can be cleaned with acetone/alcohol and 30-50% hydrochloric acid for targeted cleaning. The maintenance operation is simple and easy to use.

Accurately adapting to the scene

Monitoring PCB wastewater cleaning

Problems: The makeup of circuit board trash is hard to understand, and common ORP wires are easily affected by a lack of cleanliness. Process control, like growth and etching, is impacted by data loss.

Solution: The platinum indicator electrode of the GRT1020P can accurately measure the oxidation-reduction potential of wastewater because it is highly resistant to pollution. This helps ensure that the right amount of chemicals is used when cleaning and etching the circuit board, which helps the circuit board processing stay accurate.

Monitoring of chromium containing wastewater treatment

Problem: The reduction treatment of chromium containing wastewater requires strict control of ORP value to ensure the standard reduction of hexavalent chromium. Insufficient stability of ordinary electrodes can easily lead to treatment failure.

Solution: The electrode has high stability of ± 8mV/24h, which can monitor the potential changes during the reduction reaction process in real time. When the potential reaches the target threshold, it will prompt the adjustment of the reducing agent dosage in a timely manner to ensure that the chromium ion index after wastewater treatment meets the discharge standards.

Installation and Maintenance Guide

Installation specifications

- Open box inspection: After opening the packaging, priority should be given to checking whether there is mechanical damage to the platinum plate and electrode body. Damaged electrodes are strictly prohibited from being put into use;

- Installation and fixation: Match the corresponding specifications of protective sleeve or cable head, fix the electrode with 3/4 inch NPT thread, and ensure that the electrode testing part and the reference liquid network part can be submerged in the tested wastewater at the same time;

- Waterproof protection: The connection between the electrode wire and the electrode does not have waterproof ability and needs to be wrapped with waterproof tape or equipped with waterproof joints to prevent wastewater from infiltrating and causing electrode short circuits.

Daily maintenance and calibration

- Electrode cleaning: Gently wipe the platinum plate with acetone/alcohol cotton if it is contaminated with oil, and scrub it with 30-50% hydrochloric acid if it is contaminated with insoluble organic matter. After cleaning, rinse it with distilled water before putting it back into use;

- Standard solution configuration: Take 50ml of pH 4.00 standard buffer solution, add quinone hydroquinone reagent and stir until saturated to prepare ORP standard solution. Note that the standard solution should be used within 48 hours, as it will expire after exceeding the time limit;

- Calibration timing: It is recommended to calibrate the electrodes once a week. If there is significant drift in the monitoring data, it is necessary to recalibrate with freshly prepared ORP standard solution in a timely manner.

Sensor diagram illustration

- After opening the packaging, check whether there is mechanical damage to the sensitive bulb and electrode body of the sensor.

- Select the corresponding sensor sleeve or cable head for installation according to different electrodes;

- The connection between the sensor wire and the electrode is not waterproof, please make sure to do a good job of waterproofing.

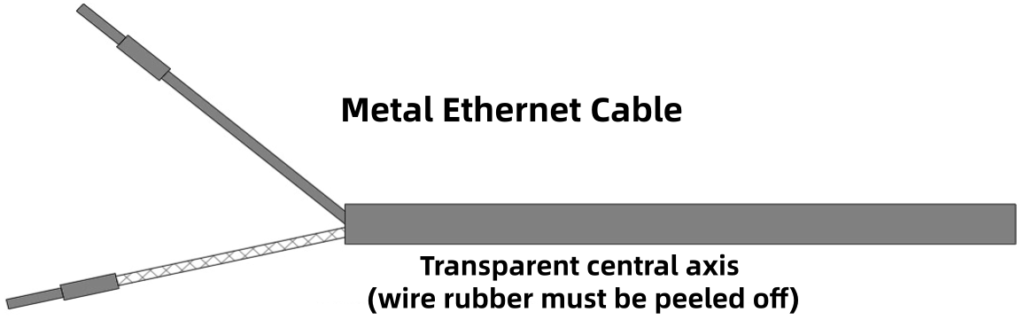

Wire stripping instructions

Attention

- The outer layer of the transparent central axis is covered with a conductive rubber layer and a metal mesh layer. When stripping, first strip the metal mesh layer into the metal mesh as shown in the picture, and be sure to removal of conductive black skin on the transparent central axis;

- The cable extends to the host without any contact points except for a dedicated junction box.

Technical Support

5 Best carbon monoxide detector for garage

10 Best carbon monoxide monitor for industrial use 2025

7+ Best Recommended Carbon Monoxide Detector for Industrial Use

What Is pH in Water? A Complete Guide to Understanding (2026)

6 Types of Industrial Oxygen Sensors

6 Best Industrial Gas Detector Manufacturers in the World

In the scenarios of circuit board and chromium containing wastewater treatment, ORP value is the core indicator for controlling the process. Ordinary electrodes either have insufficient anti pollution ability or poor data stability. However, GRT1020P, with its targeted composite electrode architecture, standardized installation design, and simple maintenance process, not only solves the monitoring problem of special wastewater, but also reduces on-site operation and maintenance costs.

Request a Quote

.png)