GRT1320PDW is a differential pH/ORP sensor developed for challenging working circumstances such strong acids, bases, and organic reagents. Instead of dual electrodes, it employs three electrode differential measurement technology to improve measurement accuracy and reliability; With a changeable salt bridge (3/4 “plastic shell version), it increases sensor life and meets chemical media monitoring demands.

★★★★★

Features

Specifications

| Parameter | Value |

|---|---|

| pH Range | 0-14 pH |

| ORP Range | -1500—+1500 mV |

| Sensitivity | pH:±0.01pH ORP:±0.5mV |

| Temperature Range | 0-130℃ |

| Pressure Range | At 130 ℃, it is 4 bar |

Scope of Application

- Suitable for applications in harsh environmental conditions, such as measuring acidic substances, alkaline substances, alcohol, hydrocarbons, aromatic compounds, lipids, ketones, and other chemicals.

Core strength

Differential technology, precise anti-interference

Adopting a three electrode differential measurement architecture, the pH value of the measuring electrode and the standard electrode is converted into a differential value relative to the background electrode of the third solution, which theoretically reduces the contamination of the reference electrode connection, eliminates the problem of closed-loop circulation, and reduces the failure time and maintenance frequency by 50%. It can still maintain a measurement accuracy of ± 0.01 pH in complex media such as alcohol and hydrocarbons.

Swap salt bridge, extend lifespan

The 3/4 “plastic shell model supports salt bridge replacement, without the need to replace the electrode as a whole. When the salt bridge becomes blocked or aged, only replacement parts are needed to restore performance, greatly reducing equipment replacement costs and extending the overall service life of the electrode by more than 30%.

Wide range tolerance, suitable for extreme working conditions

It can withstand a wide temperature range of 0-130 ℃ and withstand a pressure of 4 bar at 130 ℃. It can not only cope with strong acid and alkali environments, but also accurately measure the pH/ORP values of various chemical substances such as alcohol, ketones, and aromatic compounds, covering harsh monitoring scenarios in multiple industries.

Operating principle

1.Limitations of traditional dual electrode measurement

The traditional pH electrode adopts a dual electrode structure of measuring electrode and reference electrode. Based on the stable potential of the reference electrode, the potential difference between the measuring electrode and the reference electrode is measured to convert the pH value. However, in complex operating conditions, the reference electrode is prone to contamination by the medium, resulting in a drift of the reference potential and the formation of a closed-loop cycle, which can cause problems such as data distortion and equipment failure. The maintenance frequency is high and the data reliability is poor.

2.Three electrode differential measurement logic:

Differential sensor technology uses three measuring electrodes instead of the dual electrodes in traditional pH sensors. Relative pH values measured by measuring electrodes and standard electrodes

The differential value of the background electrode in the third solution. This technology has been proven to reduce contamination of reference electrode connections, effectively eliminate closed-loop cycling, and reduce downtime and maintenance time

3.Core advantages at the principle level

- Strong anti pollution ability: no need to rely on the absolute stable potential of the reference electrode, the solution background electrode is in direct contact with the medium, and is less affected by pollution;

- High data stability: Differential calculation can offset fluctuations in the background potential of the medium, significantly reducing data drift;

- Low maintenance cost: reduces reference electrode failures, indirectly extends the overall service life of the electrode, and reduces downtime for maintenance.

Adaptation scenario:

Chemical reaction system at high temperatures

Problem: Traditional electrodes could not work well when the temperature and pressure are over 100 °C, and strong acids and bases can quickly contaminate reference electrodes.

Solution: GRT1320PDW can handle high temperatures, and differential technology cuts down on reference pollution. It can keep an eye on the pH variations in esterification, sulfonation, and other reaction systems for a long time, making sure that the process is controlled accurately.

Organic reagent production monitoring

Pain point: Organic media such as alcohol and ketones can easily cause abnormal response and a sudden decrease in lifespan of ordinary electrodes.

Solution: The electrode is made of special materials that are compatible with various organic compounds. The high-precision ± 0.01pH can provide real-time feedback on the acidity and alkalinity of the organic synthesis system, and the salt bridge can be replaced to reduce long-term operation and maintenance costs.

Monitoring of highly corrosive wastewater

Pain points: High acidity and alkalinity wastewater in the electroplating and metallurgical industries can corrode electrodes, block liquid interfaces, and cause severe data drift.

Solution: Differential technology has strong anti pollution ability, a wide pH range suitable for extreme acid-base wastewater, and can stably upload monitoring data to the environmental protection platform to avoid compliance risks caused by data distortion.

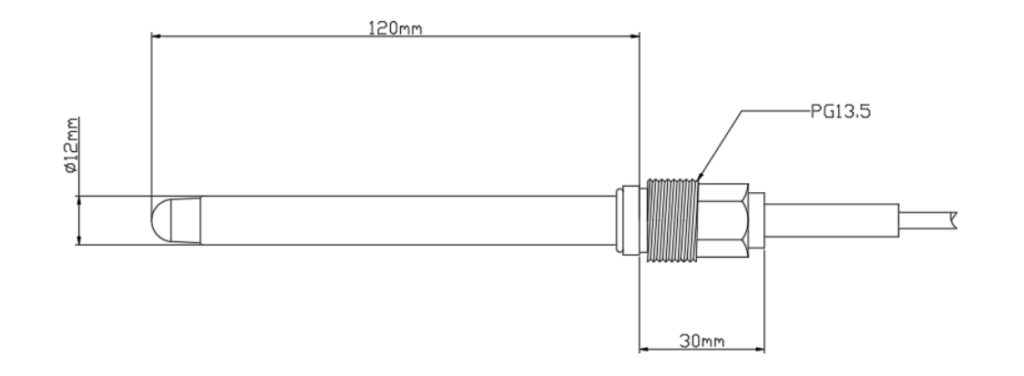

Sensor diagram illustration

- After opening the packaging, check whether there is mechanical damage to the sensitive bulb and electrode body of the sensor.

- Remove the electrode protective cover and check if there are any bubbles in the sensitive bulb of the electrode. If so, gently shake the electrode in a vertical plane to remove the bubbles;

- Select the corresponding sensor sleeve or cable head for installation according to different sensors;

- The connection between the sensor wire and the electrode is not waterproof, please make sure to do a good job of waterproofing.

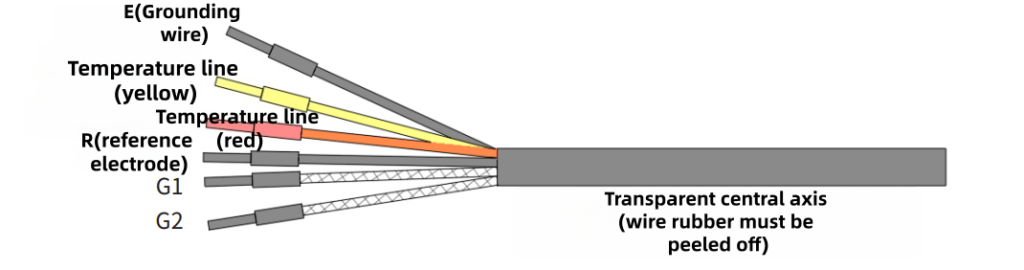

Wire stripping instructions

Attention

- The outer layer of the transparent central axis is covered with a conductive rubber layer and a metal mesh layer. When stripping, first strip the metal mesh layer into the metal mesh as shown in the picture, and be sure to removal of conductive black skin on the transparent central axis;

- The cable extends to the host without any contact points except for a dedicated junction box.

Technical Support

5 Best carbon monoxide detector for garage

10 Best carbon monoxide monitor for industrial use 2025

7+ Best Recommended Carbon Monoxide Detector for Industrial Use

What Is pH in Water? A Complete Guide to Understanding (2026)

6 Types of Industrial Oxygen Sensors

6 Best Industrial Gas Detector Manufacturers in the World

In harsh environments such as high temperature, high pressure, strong corrosion, and high organic content, ordinary pH electrodes are either “quickly scrapped” or “data distorted”. GRT1320PDW, with its three core capabilities of differential technology, replaceable salt bridge, and wide range tolerance, not only solves the measurement problem of extreme working conditions, but also reduces long-term operation and maintenance costs.

Request a Quote

.png)