The GRT1020JP is an industrial-grade ORP sensor that uses a combination of a platinum indicator electrode and a silver chloride reference electrode. It is made of PTFE, which is resistant to corrosion, and can work at temperatures between 0 and 60 degrees Celsius. It can also stably detect oxidation-reduction potential between -1999 and 1999mv. Installing electrodes is easy, and keeping them in good shape is too. This makes it a good way to keep an eye on circuit boards and wastewater treatment systems that include chromium.

★★★★★

Features

Specifications

| Parameter | Value |

|---|---|

| pH Range | 0-14 |

| Temperature Range | 0-100℃ |

| Pressure Range | 0-0.3 M Pa |

| Theoretical percentage slope (%) | ≥ 95 |

| Zero Potential | 7±0.5 |

| Thread Size | 3/4 inch NPT |

Scope of Application

- The electrode can be used in conjunction with various acidity meters and is suitable for online detection of sewage;

- If the electrode is used normally for six months, its lifespan may be shortened due to harsh environments or improper maintenance.

Three major differentiation advantages

PTFE armor, corrosion-resistant and worry free

Using high-purity polytetrafluoroethylene (PTFE) shell, compared with ordinary PPS material, the tolerance to organic solvents such as methanol and ethanol is increased by three times. In scenarios such as pharmaceutical wastewater and chemical reaction solutions, the shell swelling and cracking problems are eliminated, and the structure remains intact even after long-term immersion.

Anti poisoning design, doubling lifespan

Innovate solid gel dielectric salt bridge and build a long-distance reference diffusion channel, which can effectively block S ² ⁻, CN ⁻ and other toxic ions from eroding the reference electrode, extending the service life of the traditional electrode from three months to more than six months in harsh environments, and reducing the replacement cost.

Anti pollution and non clogging, minimalist maintenance

The anti pollution annular liquid interface design increases the contact area with sewage while reducing the risk of suspended solids adhesion and blockage. With the characteristic of not needing to supplement dielectric, only one routine cleaning calibration is required per week, saving 60% of maintenance time compared to ordinary electrodes.

Exclusive adaptation scenario

Toxic wastewater in chemical industrial parks: Monitor the pH value of chemical wastewater containing S ² ⁻ and CN ⁻, and design anti poisoning measures to avoid data interruption and ensure precise control of treatment processes.

Organic solvent wastewater in the pharmaceutical industry: resistant to corrosion by solvents such as methanol and acetone, providing stable data for monitoring antibiotic and API production wastewater.

Phenolic wastewater from coking plant: The anti fouling liquid interface is not easily blocked by tar suspended solids and is suitable for long-term online monitoring of high viscosity and high impurity water quality.

Pesticide production wastewater: wide pH range suitable for acid-base alternating reaction wastewater, high temperature tolerance to meet the monitoring needs of distilled wastewater

Usage and Maintenance Guide

Measurement and Calibration Standards

- During measurement, it is necessary to ensure that the electrode testing part and the reference liquid network part are immersed in the measured liquid at the same time to avoid data deviation.

- ORP standard solution preparation: Take 50ml of pH 4.00 standard buffer solution, add quinone hydroquinone reagent and stir until saturated. After preparation, do not use for a long time.

- The sensor standard solution (saturated quinone hydroquinone solution) has a storage time of only 48 hours and needs to be re prepared if it exceeds the expiration date.

Key points for cleaning and maintenance

- If the platinum sensor is contaminated with oil, cotton dipped in acetone or alcohol can be used to gently scrub it; If insoluble organic matter is attached, it needs to be washed with 30-50% hydrochloric acid and then rinsed clean with distilled water.

- If left idle for a long time, the sensors should be stored properly to avoid contact with corrosive substances and prevent structural damage from affecting measurement accuracy.

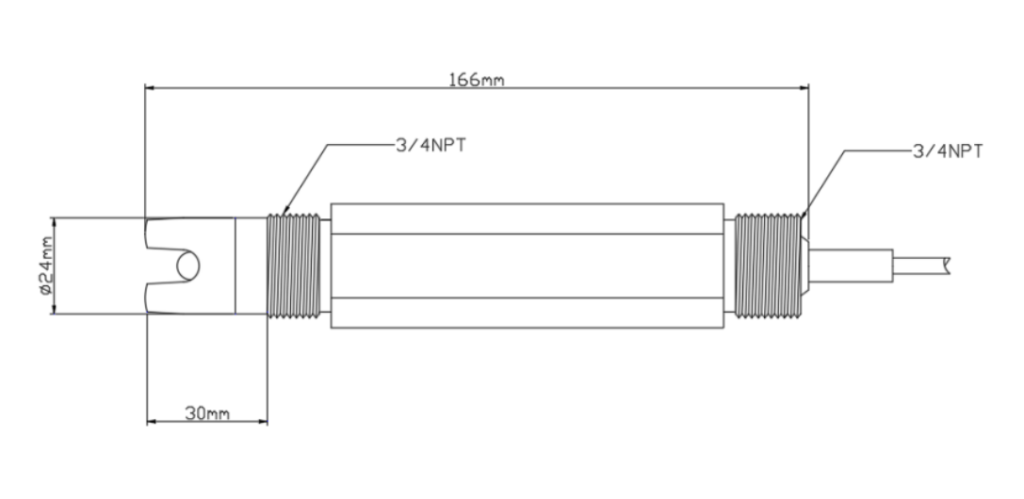

Sensor diagram illustration

- After opening the packaging, check whether there is mechanical damage to the sensitive bulb and electrode body of the sensor.

- Select the corresponding sensor sleeve or cable head for installation according to different electrodes;

- The connection between the sensor wire and the electrode is not waterproof, please make sure to do a good job of waterproofing.

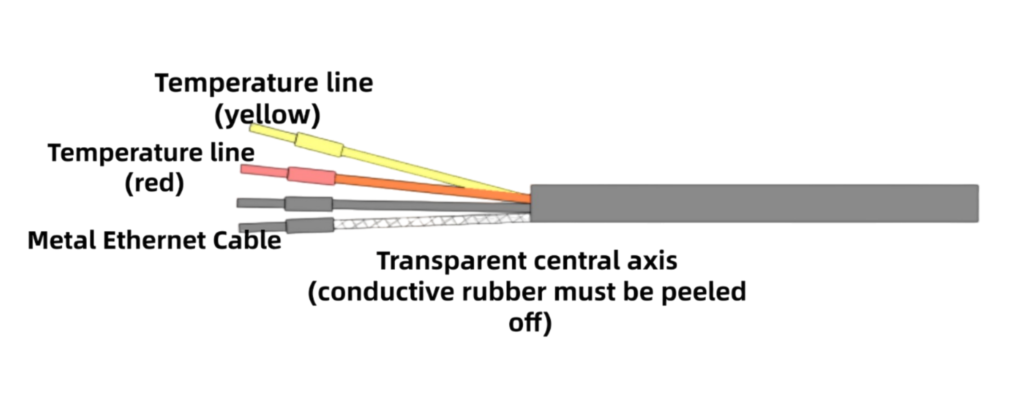

Wire stripping instructions

Attention

- The outer layer of the transparent central axis is covered with a conductive rubber layer and a metal mesh layer. When stripping, first strip the metal mesh layer into the metal mesh as shown in the picture, and be sure to removal of conductive black skin on the transparent central axis;

- The cable extends to the host without any contact points except for a dedicated junction box.

Technical Support

5 Best carbon monoxide detector for garage

10 Best carbon monoxide monitor for industrial use 2025

7+ Best Recommended Carbon Monoxide Detector for Industrial Use

What Is pH in Water? A Complete Guide to Understanding (2026)

6 Types of Industrial Oxygen Sensors

6 Best Industrial Gas Detector Manufacturers in the World

Fully functional and low-maintenance. GRT1020JP’s platinum plate resists oil pollution degradation and PTFE liquid interface decreases suspended solid binding. With its complex composition, circuit board wastewater only requires weekly cleaning. Platinum plates with heavy oil contamination can be simply cleaned with a soft tissue soaked in acetone and washed with distilled water without extra care. Choosing GRT1020JW means choosing to make rigorous water quality monitoring more worry free and reliable!

Request a Quote

.png)