The anti poisoning gel dielectric salt bridge of GRT3010 can prevent the corrosion of toxic ions such as S ² and CN, and prevent the electrode from “poisoning failure”. The design of the annular PTFE liquid interface reduces the risk of blockage and achieves long-term online stable detection. Using special glass sensitive film and low internal resistance, the response speed is fast, the data is reliable, no dielectric is required, and the maintenance cost is low.

★★★★★

Features

Specifications

| Parameter | Value |

|---|---|

| Measurement Range | 0-14 pH |

| Theoretical percentage slope | ≥95% |

| Zero potential | 7±0.5 |

| Temperature Range | 0-60℃ |

| Pressure Range | 0-0.4 M Pa |

| Internal Resistance | ≤ 250 MΩ at 25 degrees |

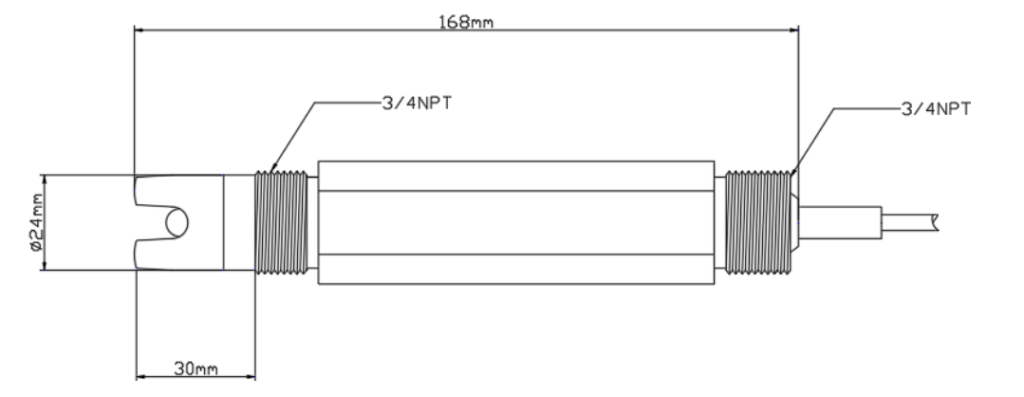

| Thread Size | 3/4 inch NPT |

Scope of Application

- Suitable for environmental protection, lime slurry, and online testing.

Three core advantages define industrial grade reliability

Strong anti toxicity and longer lifespan

The gel dielectric salt bridge technology can specifically block toxic ions such as S ² ⁻ and CN ⁻, solve the problem that traditional electrodes are prone to failure in toxic wastewater from the root, significantly extend the service life and reduce the replacement cost.

Anti pollution and anti blockage, more worry free operation and maintenance

The circular polytetrafluoroethylene (PTFE) liquid interface has a scientifically designed structure and is not easily attached to suspended solids. It can be detected online for a long time, reducing the frequency of manual cleaning, and is especially suitable for high sludge and high impurity sewage scenarios.

No need for fluid replacement design, more convenient to use

The use of gel dielectrics eliminates the need to replenish dielectrics as frequently as traditional electrodes, which greatly reduces the amount of maintenance. Combined with the design of terminal blocks and standard threads, the installation is convenient, and the reinforced shielded cable also has excellent anti-interference and waterproof performance.

Full coverage of adaptation scenarios

Environmental Protection Online Monitoring: Accurate, Stable, and Reliable Data for Environmental Regulatory Reporting

Industry wastewater treatment: anti-toxic characteristics for toxic wastewater, discharge monitoring compliance.

Municipal sewage system: Anti-pollution design to reduce maintenance and improve suspended solids water quality.

Chemical wastewater detection: tolerating complicated components, suited for real-time acidic and alkaline wastewater monitoring.

Environmental sewage monitoring: long-term online detection, stable and compliant data

Electroplating wastewater treatment: excellent anti toxicity performance, ensuring accurate monitoring of process water quality

Maintenance

- Before you begin the process of taking measurements, you should clean the electrode by rinsing it with distilled water and then pat it dry using a piece of filter paper.

- In order to maintain a full protective cap, it is necessary to keep it filled with a 3.3mol/L solution of potassium chloride when it is not being used.

- Avoid leaving yourself in distilled water, protein solutions, or acidic chloride solutions for an extended period of time.

- Use a small amount of an acidic solution of hydrochloric to cleanse If you notice that the glass membrane has become foggy or has deposits on it, clean it with water.

- In order to ensure optimal functioning, the pH meter should be cleaned and calibrated on a weekly basis. When it comes to the consistent application of lime slurry, this is quite crucial.

- The sensor will be unable to regain its response if you are unable to carry out the calibration procedure on the sensor by employing the aforementioned procedures for maintenance and upkeep. Could you please buy a new sensor?

Sensor diagram illustration

- After opening the packaging, check whether there is mechanical damage to the sensitive bulb and electrode body of the electrode.

- Remove the sensor protective cover and check if there are any bubbles in the sensitive bulb of the electrode. If so, gently shake the sensor in a vertical plane to remove the bubbles.

- Select the corresponding sensor sleeve or cable head for installation according to different electrodes.

- The connection between the sensor wire and the electrode is not waterproof, please make sure to do a good job of waterproofing.

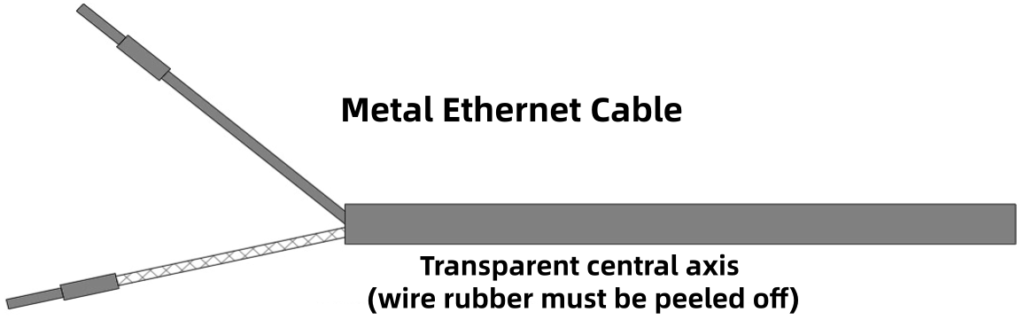

Wire stripping instructions

Attention

- The outer layer of the transparent central axis is covered with a conductive rubber layer and a metal mesh layer. When stripping, first strip the metal mesh layer into the metal mesh as shown in the picture, and be sure to removal of conductive black skin on the transparent central axis;

- The cable extends to the host without any contact points except for a dedicated junction box.

Technical Support

5 Best carbon monoxide detector for garage

10 Best carbon monoxide monitor for industrial use 2025

7+ Best Recommended Carbon Monoxide Detector for Industrial Use

What Is pH in Water? A Complete Guide to Understanding (2026)

6 Types of Industrial Oxygen Sensors

6 Best Industrial Gas Detector Manufacturers in the World

Antitoxic gel blocks the ion erosion, antifouling liquid interface says goodbye to clogging troubles, and maintenance free design saves labor costs – GRT3010 uses three core advantages to help you completely say goodbye to the trouble of frequent electrode replacement and tedious maintenance. Choose GRT3010, it is a reliable choice in the fields of environmental protection, sewage, chemical engineering, and more!

Request a Quote

.png)