Introduction to Types of Industrial Oxygen Sensors

Industrial oxygen sensors play a critical role in monitoring and controlling oxygen levels across multiple sectors, including manufacturing, chemical processing, healthcare, and environmental monitoring. Understanding the Types of industrial oxygen sensors helps businesses select the right technology for safety, precision, and operational efficiency.

Table of Contents

What Are Types of Industrial Oxygen Sensors?

Industrial oxygen sensors are devices designed to measure the concentration of oxygen in gases or environments. They are essential for safety, process optimization, and regulatory compliance. The Types of industrial oxygen sensors differ in detection principles, accuracy, lifespan, and application suitability.

6 Types of Industrial Oxygen Sensors

1. Electrochemical Oxygen Sensors

Electrochemical sensors are widely used due to their high precision and sensitivity. They operate by generating an electrical current proportional to oxygen concentration. These sensors are compact, cost-effective, and ideal for portable instruments.

2. Zirconia Oxygen Sensors

Zirconia oxygen sensors utilize a solid‑state electrolyte and operate at high temperatures. They are highly durable and commonly used in combustion systems, automotive exhaust monitoring, and industrial furnaces.

3. Optical (Luminescent) Oxygen Sensors

Optical sensors measure oxygen by detecting changes in fluorescence or luminescence. These sensors offer fast response times and long service life, making them suitable for biotechnology, medical devices, and environmental applications.

4. Infrared (IR) Oxygen Sensors

Infrared sensors work by analyzing the absorption of infrared light by oxygen molecules. They provide stable, drift‑free readings and are ideal for harsh environments or applications requiring continuous monitoring.

5. Paramagnetic Oxygen Sensors

Oxygen is naturally paramagnetic. These sensors measure oxygen concentration by detecting magnetic characteristics. They are exceptionally precise and are used in laboratories and industrial gas analyzers.

6. Galvanic Oxygen Sensors

Galvanic sensors function similarly to electrochemical types but generate their own voltage. They are low power, easy to integrate, and commonly found in diving equipment, medical devices, and portable analyzers.

Comparison Table of Sensor Types

| Sensor Type | Accuracy | Lifespan | Typical Applications |

|---|---|---|---|

| Electrochemical | High | 1–2 years | Portable analyzers, industrial safety |

| Zirconia | Very High | 5+ years | Furnaces, combustion control |

| Optical | High | 5+ years | Biotech, environmental |

| Infrared | Medium–High | 3–5 years | Harsh industrial environments |

| Paramagnetic | Very High | Long | Laboratory, high‑precision analysis |

| Galvanic | Medium | 1–3 years | Medical, diving, portable tools |

Applications of Industrial Oxygen Sensors

The Types of industrial oxygen sensors are chosen based on application needs such as sensitivity, accuracy, environmental conditions, and cost. Common industries include:

- Petrochemical & oil refining

- Environmental monitoring

- Gas analyzer manufacturing

- Industrial safety systems

- Metallurgy & combustion control

- Biotechnology and medical equipment

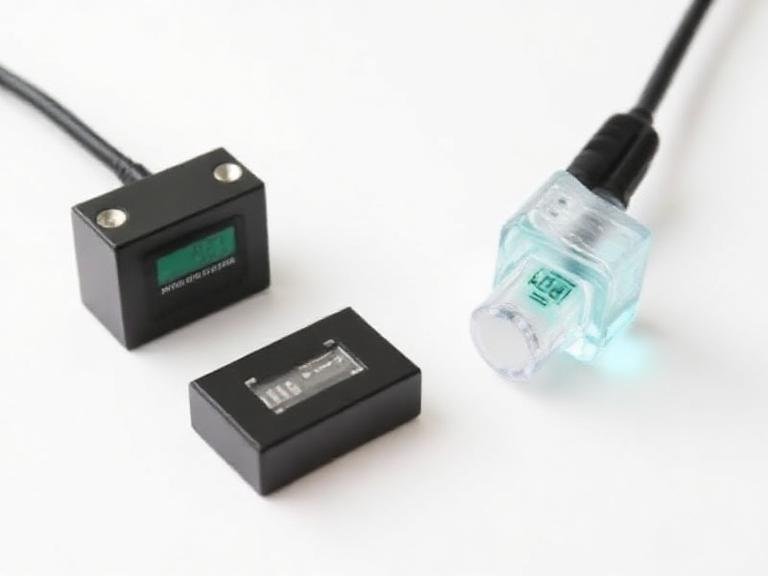

Spotlight: Sino-Inst 800 Series Gas Sensor Module

The Sino-Inst 800 Series Gas Sensor Module is a versatile and high-performance detection solution compatible with multiple Types of industrial oxygen sensors. It supports electrochemistry, catalytic combustion, infrared NDIR, thermal conductivity, and PID principles.

Key Features

- Compact and lightweight

- Supports multiple professional gas sensing principles

- High precision, fast response

- Intrinsically safe circuit design with hot-swap capability

- Automatic temperature and humidity compensation

- Simultaneous analog and serial output

- Built-in zero point fine-tuning

- Low power consumption; supports mobile power

- Compatible with computers for calibration

Specifications

| Parameter | Value |

|---|---|

| Working Voltage | DC24V ±10% |

| Accuracy | ±2% F.S |

| Response Time | < 30s |

| Operating Temperature | -30°C to 70°C |

| Humidity | 0–100% RH |

| Output Signal | RS485 / 4–20mA / optional voltage outputs |

Frequently Asked Questions

Which type of industrial oxygen sensor is most accurate?

Paramagnetic and zirconia sensors offer the highest accuracy for industrial applications.

Which sensor is best for harsh environments?

Infrared and zirconia sensors perform well in extreme temperatures and corrosive conditions.

What is the average lifespan of an oxygen sensor?

Depending on type, lifespan ranges from 1 year (electrochemical) to over 5 years (zirconia, optical).

.png)