The pH/ORP controller enables long-term, continuous, and precise monitoring and automatic control of water’s acidity/alkalinity (pH value) and oxidation-reduction potential (ORP). Its core pH/ORP electrode detects the activity or oxidation-reduction potential of hydrogen ions in the water and converts it into a precise concentration reading.

Installing a reliable online pH/ORP controller in industrial wastewater treatment, chemical production, or water purification processes can significantly reduce the risks of equipment corrosion, product defects, or disinfection failure and environmental pollution caused by pH loss or ORP abnormalities.

Product classification

What is pH/ORP?

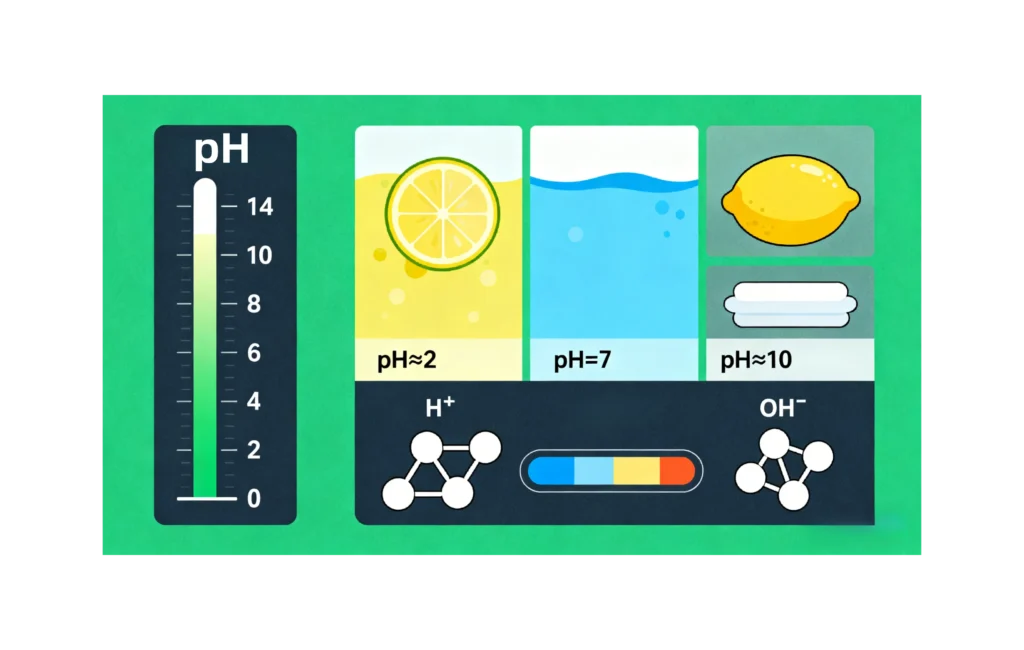

What is pH?

pH, also known as the hydrogen ion concentration index or acid-base value, is an indicator of the activity of hydrogen ions in a solution and is commonly used to measure the acidity or alkalinity of a solution. At normal temperature and pressure (approximately 25°C and 298K), the closer the pH is to 0, the more acidic the solution; the closer the pH is to 14, the more alkaline the solution. A pH < 7 indicates an acidic solution; a pH > 7 indicates an alkaline solution; and a pH = 7 indicates a neutral solution.

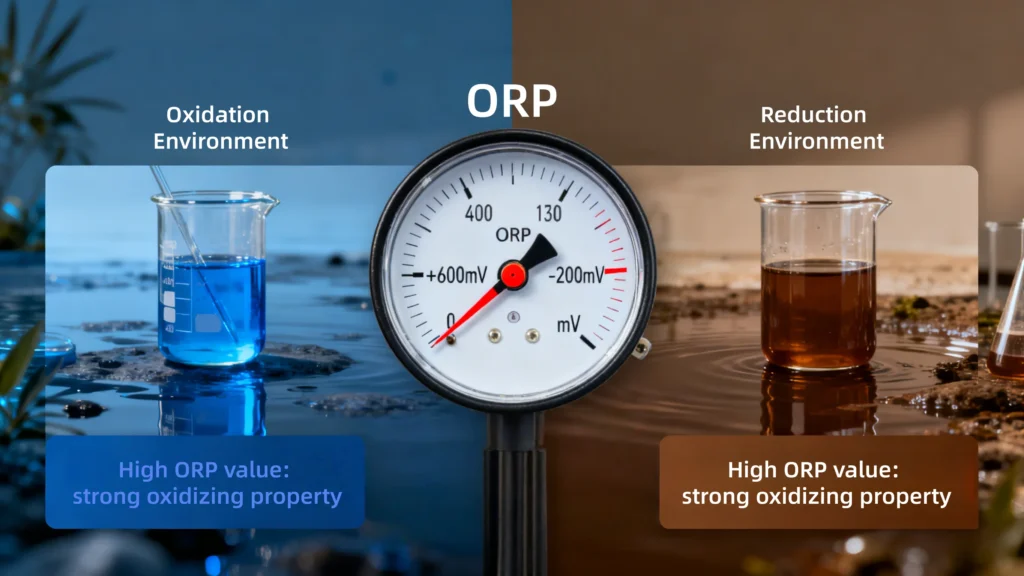

What is ORP?

ORP is the difference between the redox potential of the indicator electrode and the redox potential of the comparator electrode in the liquid, providing a comprehensive indicator of the redox state of the entire system.A low ORP value indicates a high content of reducing substances or organic pollutants in the wastewater treatment system, low dissolved oxygen concentration, and a dominant reducing environment.A high ORP value indicates a low concentration of organic pollutants in the wastewater, high concentration of dissolved oxygen or oxidizing substances, and a dominant oxidizing environment.

How to choose a suitable ph/orp controller

In water quality monitoring projects, choosing the right pH/ORP controller and electrode combination is the key to ensuring accurate data and stable system operation! Based on real-world application scenarios, we provide a scientific selection guide to help you easily avoid selection pitfalls and achieve the optimal balance between monitoring efficiency and cost.

According to the measured parameters

Select the model accurately according to measurement parameters to avoid functional redundancy or insufficiency.

- pH only: Select the pH-specific model

- ORP only: Select the ORP-specific model

- pH + ORP combination: Select a dual-channel or switchable model (e.g., RP-3000 supports multiple parameter configurations)

According to range and accuracy

Different scenarios have significant differences in monitoring accuracy requirements, and precise matching is necessary to avoid ‘over-provisioning’ or ‘insufficient accuracy’.

- pH Measurement Range and Accuracy:

- General Water Treatment: pH 2–12,Accuracy ± 0.1 pH Sufficient

- Laboratory/High Requirements:Accuracy ± 0.02 – 0.05

- ORP Measurement Range and Accuracy:

- Regular: −1000 mV + 1000 mV,Accuracy ± 5–10 mV

- Stability and Interference Immunity:

- Shielded, well grounded, analog/digital filtering enhances stability

According to the matching with the electrodes

The perfect compatibility between the controller and the electrode is the foundation for the efficient operation of the monitoring system, and it needs to be considered comprehensively from three aspects: medium temperature, installation method, and connection compatibility.

- Medium and Temperature:

- High Temperature/Corrosive: Select glass electrode (For example:GRT1320 series, HF1120 series) + SS316 sheath

- General Online: Select plastic shell electrode (For example:GRT1020/GRT1030 series) + PP sheath

- Installation Method:

- Immersion/Flow-through/Pipe, select corresponding electrode and accessories (For example:PP-34 series, SS304-135)

- Connection Compatibility:

- Controller port and electrode connector are compatible (For example:S8/VP/Threaded)

According to medium properties

Different water quality media have significantly different requirements for monitoring equipment, and targeted selection is the only way to effectively solve practical problems.

- Containing solids/suspended matter: Requirement for anti-fouling electrodes and flow channels; controller must support stable filtering

- High salt/high ionic strength: Electrode reference design and anti-polarization capability; temperature compensation algorithm for the controller

- Strong oxidizing/reducing agents: Prioritized ORP control strategy and anti-interference design

Application scenarios

Our pH/ORP controllers are the smart core that makes it possible for many businesses to accurately control water quality and make sure that production is safe. The following are common use cases:

Industrial Wastewater Treatment

The pH of wastewater changes a lot, and direct release can damage pipe networks, mess up biological treatment systems, and lead to fines for damaging the environment. Putting in an online pH controller at the equalization tank or discharge point lets you watch the pH of the wastewater in real time and add acid/base neutralizers automatically. This keeps the pH stable within the accepted range of 6–9.

Chemical Production Process

Chemical reactions are extremely sensitive to pH and oxidation-reduction potential (ORP). Improper control can lead to incomplete reactions, decreased product quality, and even safety accidents. Corrosion-resistant pH/ORP controllers and electrodes are installed in reaction and neutralization vessels to precisely control the reaction environment and ensure that process conditions are always optimal.

Water Purification and Ultrapure Water Preparation

Reverse osmosis (RO) membranes are sensitive to the pH of the feed water. If the feed water is too acidic or alkaline, the membranes can scale or work less well. pH is a very important way to tell if water is ultrapure.To keep an eye on changes in the water quality, put in a high-precision pH sensor either before or after the RO system. Fine-tuning protects expensive membrane parts and makes sure that the product water is of good quality.

.png)