The SI-10HT High Temperature Mass Flow Meter enables rapid and accurate measurement of the volumetric flow rate and mass flow rate of process gases, liquids, and vapors. The SI-10HT High Temperature Mass Flow Controller utilizes a custom-designed high-speed proportional control valve for precise control of the volumetric and mass flow rates of gases, liquids, and vapors.

The SI-10HT High Temperature Mass Flow Controller & Meter features an integrated multi-functional digital display, allowing users to control setpoints and PID valve adjustments via on-screen buttons. It also supports analog input/output and RS-485 digital communication. When measuring liquids, a unique vent allows for easy air removal.

★★★★★

Features

Specifications

| Series | SI-10HT | |||||

| Model | LC | LM | MC | MM | BC | BM |

| Measuring Range | Gas:0-(2,5,10…1000)SCCM, 0-(1,5,10…30)SLM | Gas:0-(30,40,50…300)SLM | Gas:0-(300,400,500…3000)SLM | |||

| Liquid:0-(2,5,10…500)SCCM | Liquid:0-(500,600…1000)SCCM, 0-(1,2,3…10)SLM | Liquid:0-(1,2,10…20)SLM | ||||

| Steam:0-(2,5,10…1000)SCCM, 0-(1,2,3…10)SLM | Steam:0-(10,20,30…100)SLM | Steam:0-(100,150,200…500)SLM | ||||

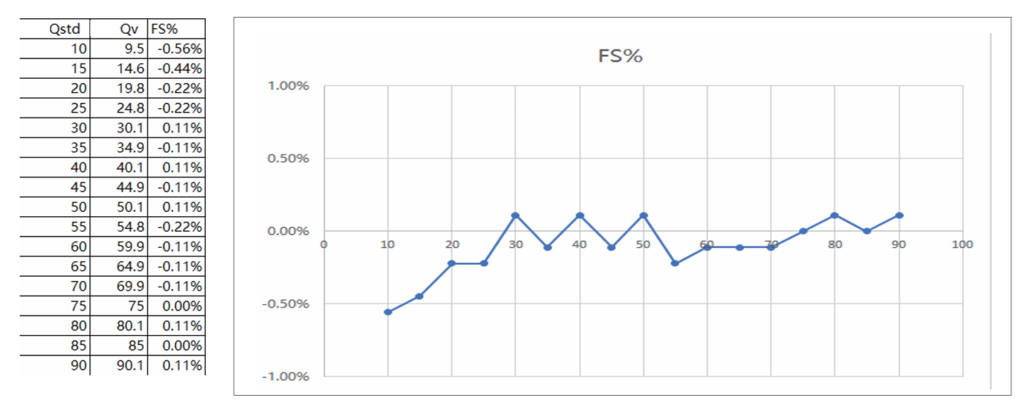

| Accuracy | ±1.0%F.S | |||||

| Repeatability | ±1%F.S | |||||

| Zero Drift & Full-Scale Drift | 0.02% F.S/ ºC/Atm | |||||

| Operating Differential Pressure | 0.1~0.5MPa (specify when ordering) | |||||

| Turndown Ratio | 50:1 | 100:1 | 50:1 | 100:1 | 50:1 | 100:1 |

| Typical Response Time | 200 milliseconds (adjustable) | |||||

| Analog Output | 0~5V、4~20mA | |||||

| Digital Output | RS232/485, MODBUS protocol | |||||

| Power Supply | 24VDC | |||||

| Measurable temperature | 80~200℃; Customized upgraded version can measure 350℃ | |||||

| Operating Temperature | +10~+50℃ | |||||

| Operating Voltage Drop | <0.01Mpa | |||||

| Operating Pressure | <1MPa | |||||

| Electrical Connection | DB15 hole | |||||

| Protection Rating | IP40 | |||||

| Leak Rate | 1×10-9Pa m³/S | |||||

| Valve | Valve normally closed | / | Valve normally closed | / | Valve normally closed | / |

| Base Material | Stainless steel | |||||

| Seal Material | Fluororubber, nitrile rubber, EPDM, perfluoroelastomer | |||||

| Body Thread | G3/8 internal thread | G1/2 internal thread | ||||

| Connection | Foldings, ferrules, quick-connect fittings, VCRs, flanges, etc. | |||||

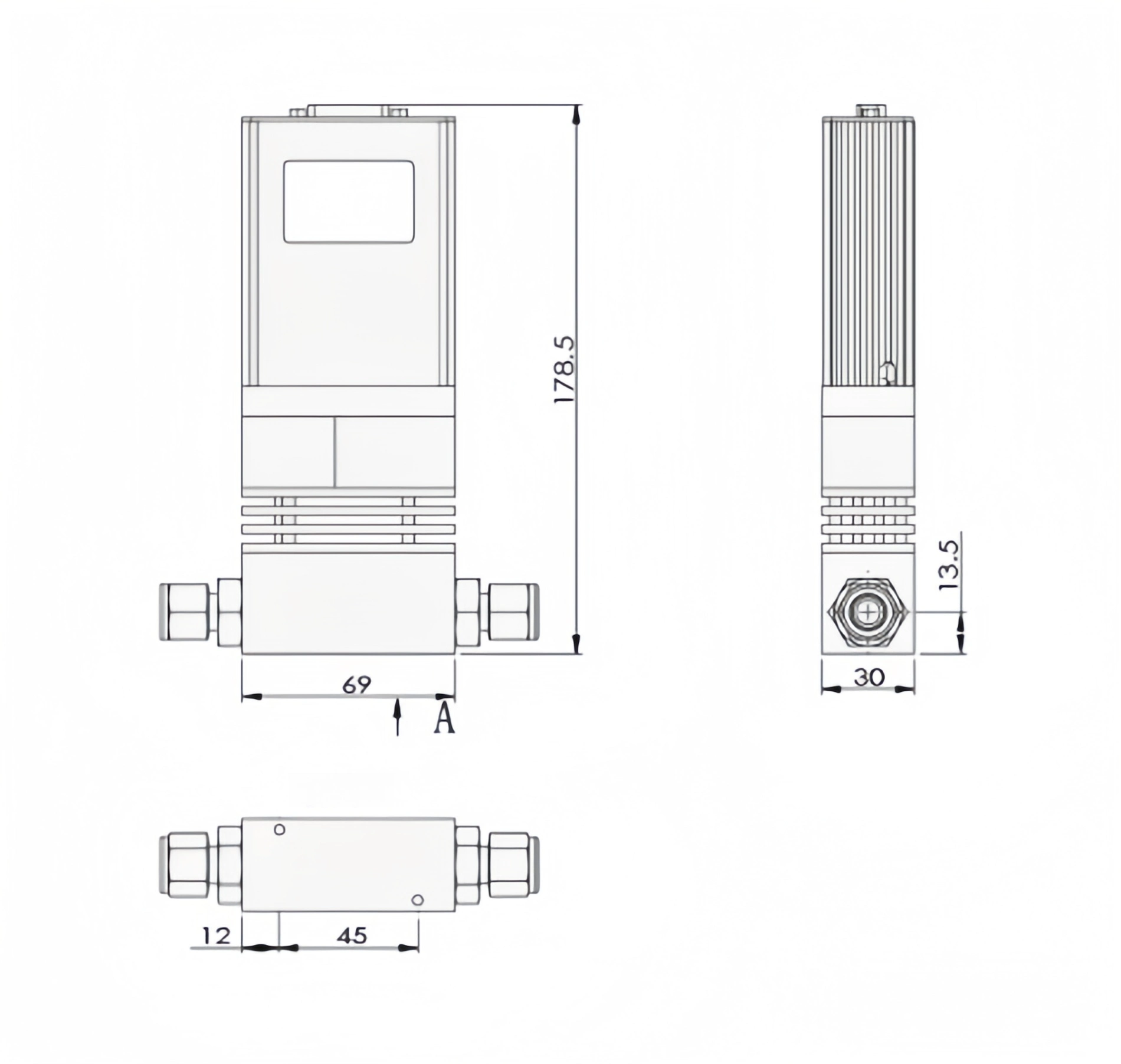

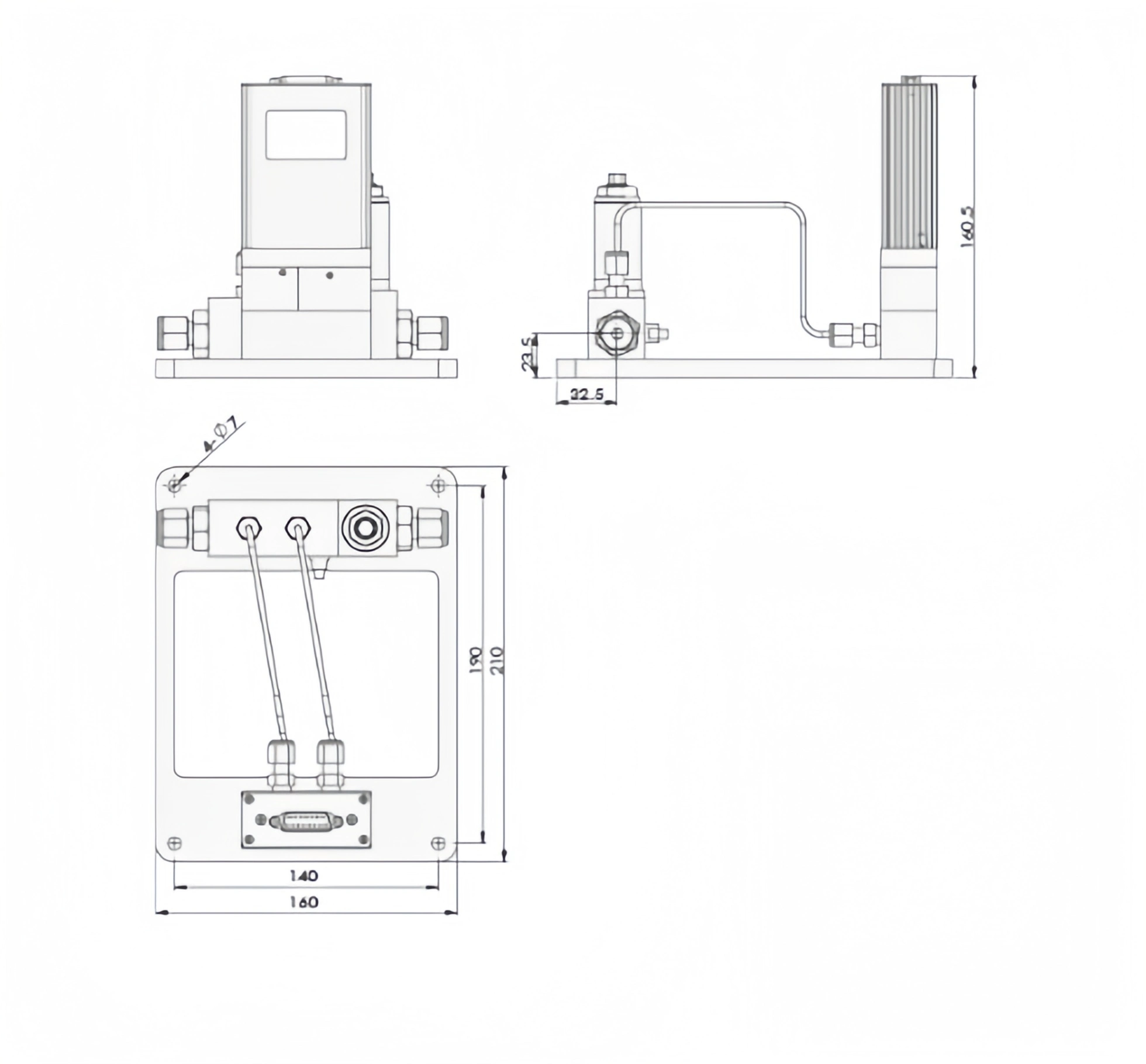

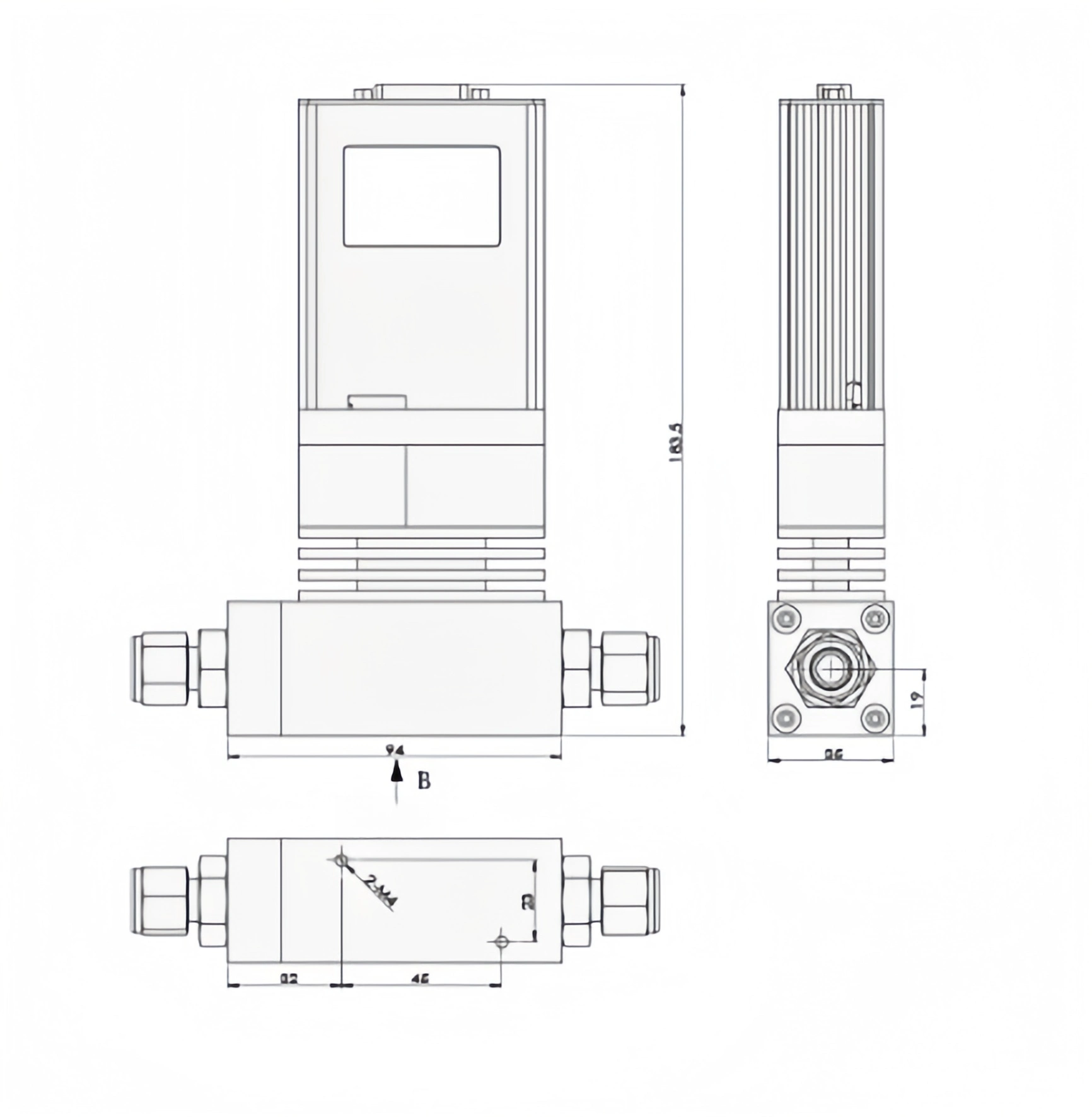

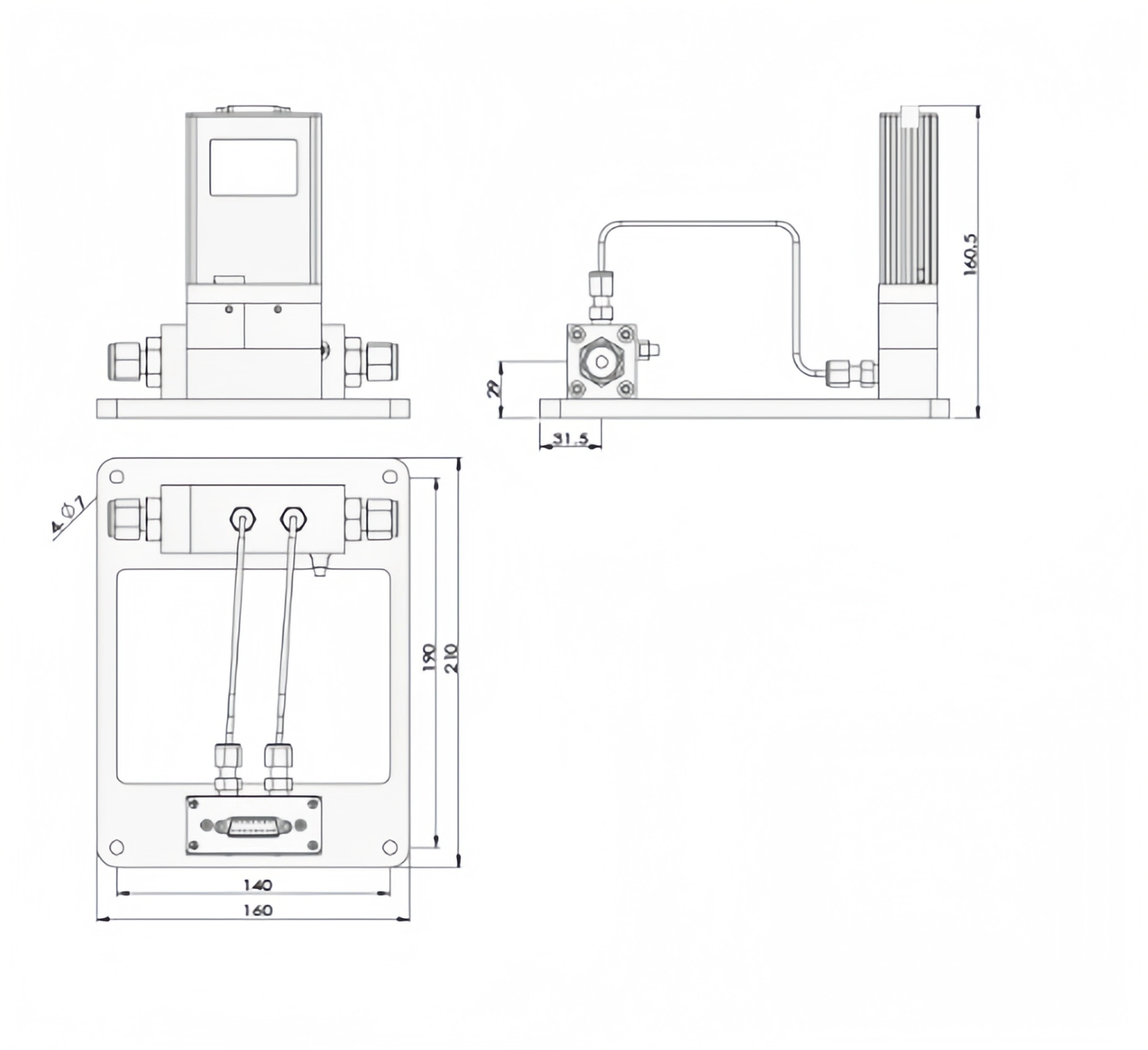

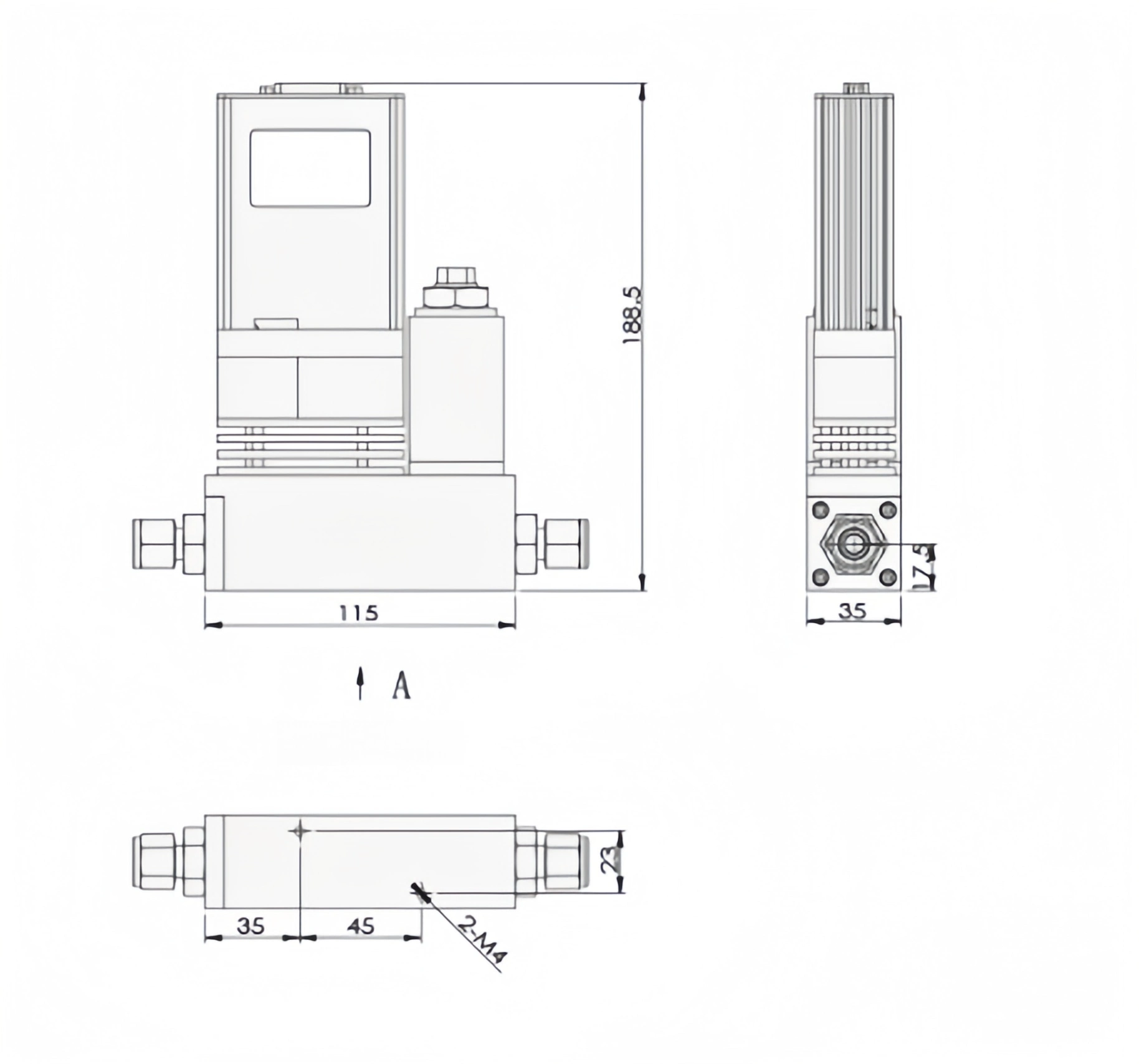

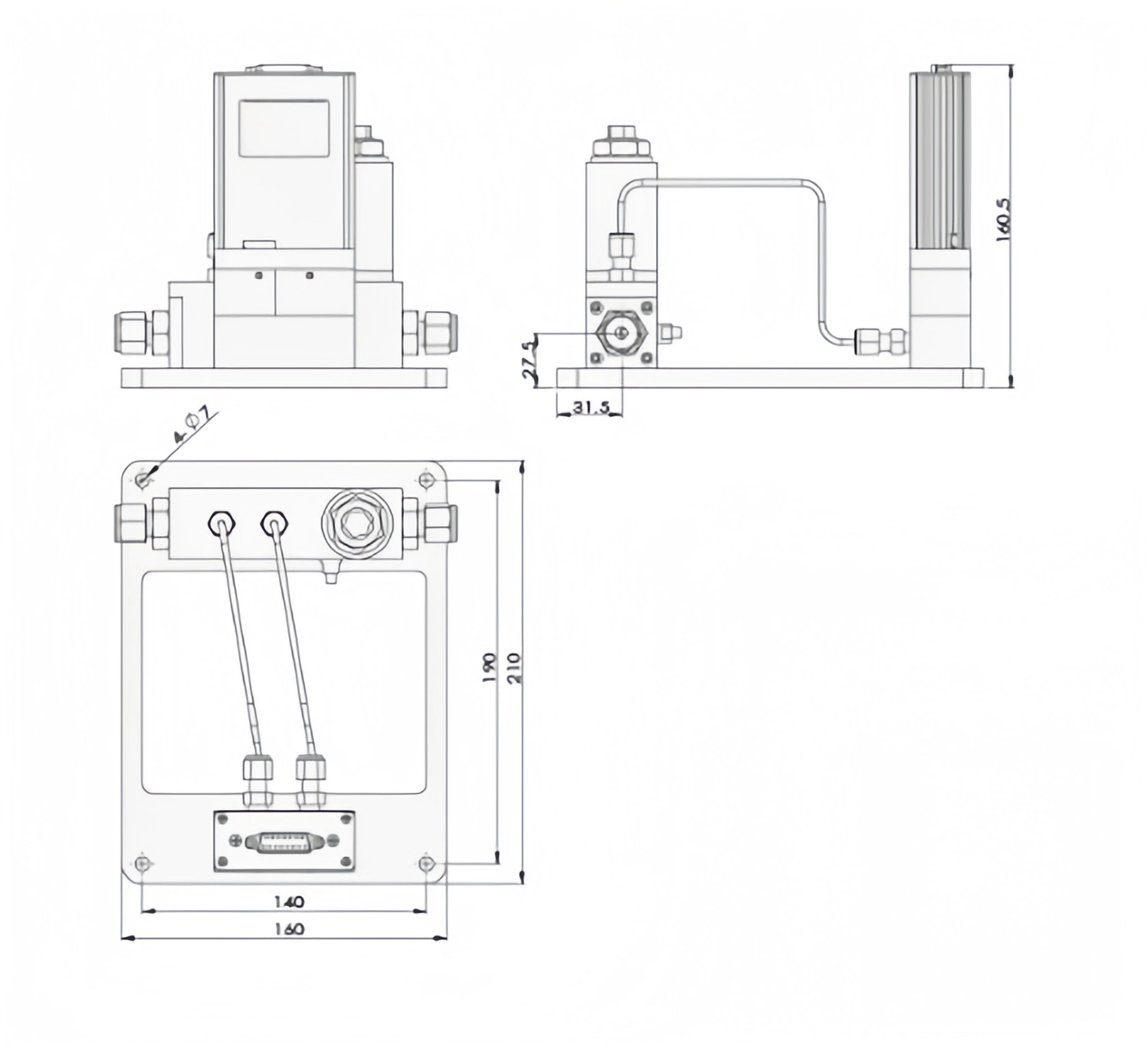

SI-10HT-MC High Temperature Mass Flow Controller-Meter Dimension

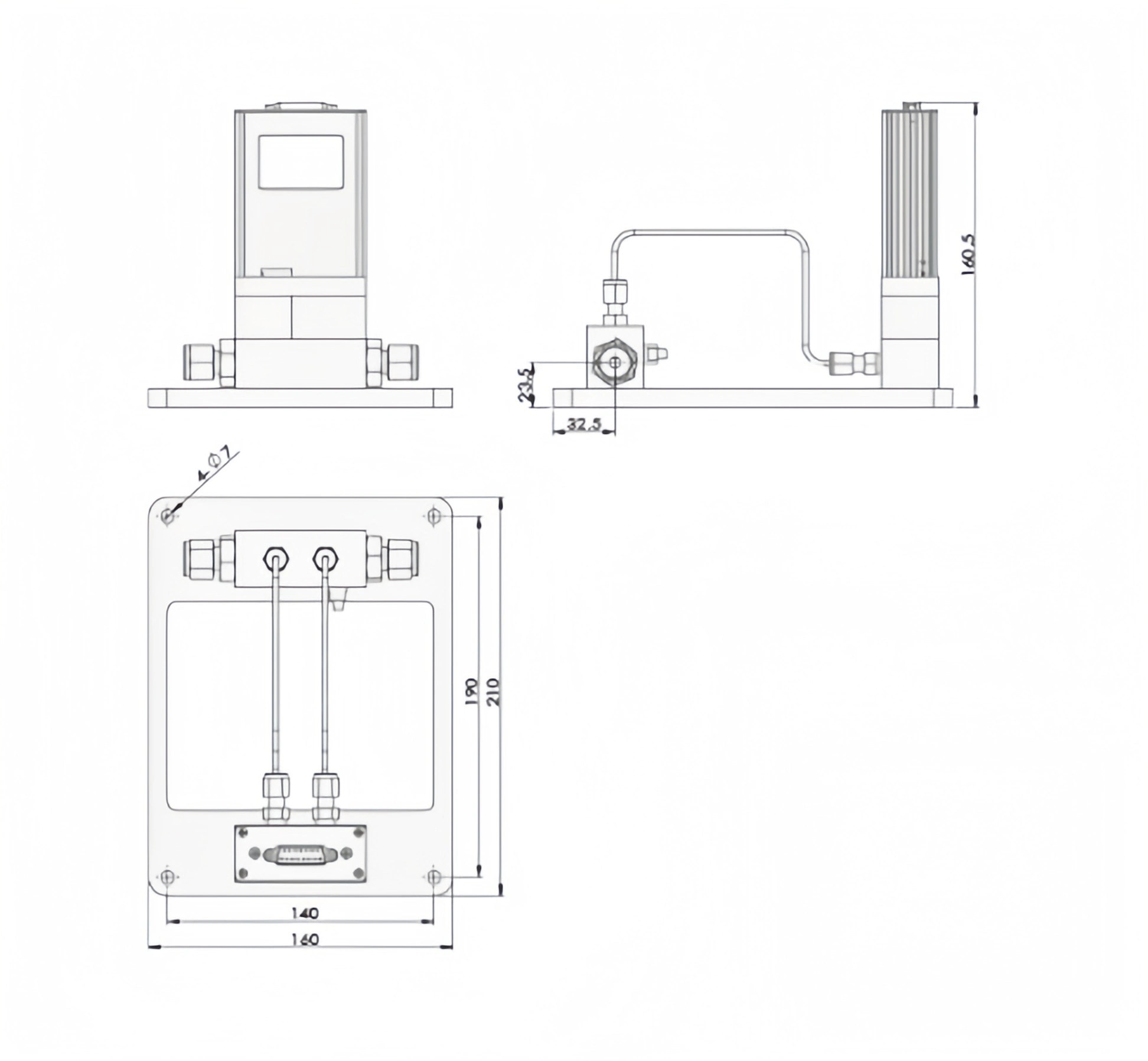

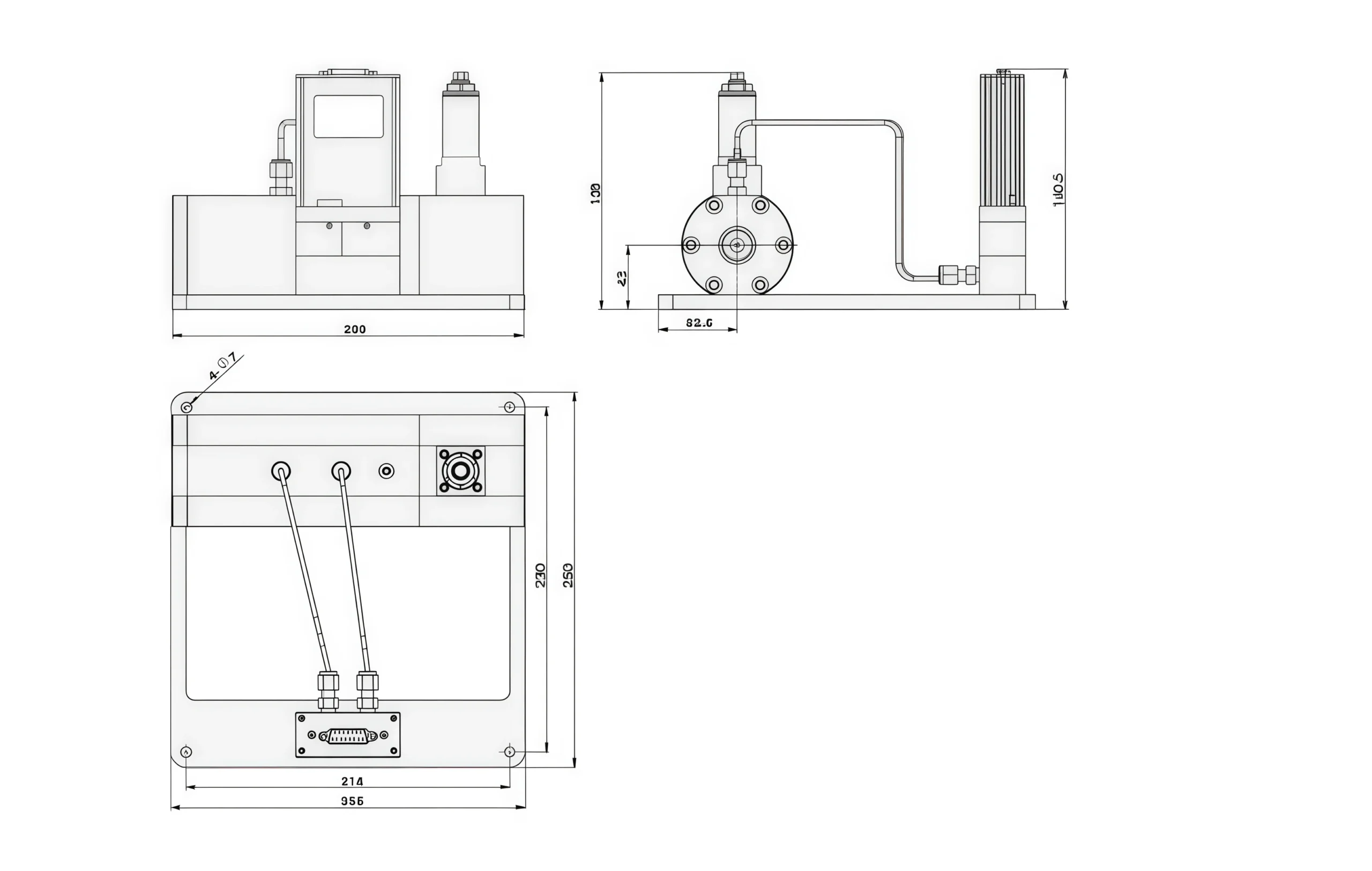

SI-10HT-MC High Temperature Mass Flow Controller-Meter Dimension

Calibration Data

Steam Flow Measurement and Control

In modern industrial processes, accurate steam flow measurement is crucial for process control, energy efficiency management, and safe production. Steam flow meters are widely used in various industries, including energy, chemical, pharmaceutical, and food processing. However, steam flow measurement faces a series of complex technical challenges, especially in terms of performance under different pressure and temperature conditions.

For example, in low-pressure environments, the boiling point of water decreases significantly, making steam more prone to phase change and leading to measurement errors. Conversely, under normal or high-pressure conditions, high-temperature steam may exceed the temperature limits of traditional flow sensors, causing equipment damage or measurement distortion.

To address these challenges, the Sino-Inst laminar flow differential pressure mass flow controller offers an innovative solution. This technology is based on the principle of laminar flow differential pressure, directly calculating mass flow rate by accurately measuring the pressure difference change of the fluid in laminar flow conditions, without relying on complex temperature or pressure compensation. This method not only avoids the limitations of traditional steam flow meters under operating conditions but also significantly improves the accuracy and reliability of the measurement.

In the semiconductor manufacturing industry, steam flow control has high requirements for process precision. Sino-Inst laminar differential pressure mass flow controllers can stably handle high-purity steam and specialty gases, effectively avoiding phase transition problems caused by boiling point reduction even under low-pressure conditions. Its sensors utilize high-temperature resistant materials and innovative design, ensuring long-term stability in high-temperature environments, thus meeting the stringent requirements of continuity and repeatability in semiconductor production lines.

The biopharmaceutical industry is another typical application scenario. Steam is widely used in sterilization and process heating, but traditional flow meters often have shortened lifespans due to high temperatures and pressures, or measurement deviations due to boiling point changes under low-pressure conditions. Sino-Inst laminar differential pressure technology, through its unique temperature-resistant design and anti-phase-change capabilities, achieves precise control of steam quality, ensuring the aseptic requirements and compliance of pharmaceutical processes.

The food and beverage industry also benefits from this technology. During distillation, sterilization, and filling processes, steam flow needs to be precisely controlled to maintain product quality. Sino-Inst flow controllers can adapt to varying pressure environments, ensuring the accuracy of flow data even when a sudden drop in system pressure causes a decrease in the boiling point of water. Meanwhile, its high-temperature resistance avoids the risk of sensor failure under high-pressure steam, reducing equipment maintenance costs and production interruptions.

In new energy fields such as solar thermal and nuclear power systems, steam is often used for energy conversion and transmission. These systems often involve high-temperature and high-pressure conditions, making it difficult for traditional flow meters to operate stably for extended periods. The Sino-Inst laminar flow differential pressure mass flow controller, with its robust design, maintains high performance in high-temperature environments while accurately addressing the challenges posed by pressure fluctuations, providing strong support for efficiency and safety in the energy industry.

The core advantages of the Sino-Inst laminar flow differential pressure mass flow controller lie in its direct mass flow measurement capability, eliminating intermediate conversion errors; its sensor structure is simple and reliable, suitable for various fluid media; and, more importantly, it effectively suppresses phase change effects under low-pressure conditions and exhibits excellent temperature resistance under high-temperature environments. These characteristics make it an ideal choice for steam flow measurement in numerous industrial scenarios.

Technical Support

How Does a thermal mass flow controller working principle?

8 Best Mass Flow Controller Manufacturers

5 Best Digital Mass Flow Controllers for Precision Gas Flow Measurement

Guide to Connecting a Thermal Mass Flow Controller to a PLC

The SI-10HT series is a mass flow controller/meter specially developed by our company for high-temperature media. The basic model can measure up to 200℃, while the upgraded model can measure up to 350℃. It adopts a split-type structure, with a maximum range of 1200 slm, capable of measuring superheated steam up to 380℃. Its high accuracy, fast response, multi-variable measurement, and 50:1 adjustable range ratio are highly favored by users.

If you need high-temperature media flow measurement and control, please contact our sales engineers for parameter customization!

Request a Quote

Related Products

SI-10HT High Temperature Mass Flow Controller/Meter 200℃/350℃

The SI-10HT High Temperature Mass Flow Meter enables rapid and accurate measurement of the volumetric flow rate and mass flow rate of process gases, liquids, and vapors. The SI-10HT High Temperature Mass Flow Controller utilizes a custom-designed high-speed proportional control valve for precise control of the volumetric and mass flow rates of gases, liquids, and vapors.

Product SKU: SI-10HT High Temperature Mass Flow Controller/Meter

Product Brand: Sino-Inst

Price Valid Until: 2099-09-09

Product In-Stock: InStock

5

.png)