The SI-10FC laminar differential pressure mass flow controller is designed based on the law of conservation of mass, Bernoulli’s equation, and Hagen-Poiseuille’s law. It calculates the mass flow rate of a fluid by measuring the pressure difference across the pipe. It features no thermal drift and no response hysteresis, and can simultaneously display and output instantaneous flow rate, cumulative flow rate, pressure, and temperature. For additional control functions, an electromagnetic proportional control valve and built-in PID control can be added.

★★★★★

Features

Specifications

| Technical Parameters | Flow Meter | Flow controller |

| Measuring Range | Low Range: 100SCCM~30SLM | |

| Medium Range: 30SLM~300SLM | ||

| Large Range: 500SLM~3000SLM | ||

| Accuracy (under standard conditions after zeroing) | ±1% F.S | |

| Repeatability | ±1% F.S | |

| Zero drift & full-scale drift | 0.02% F.S/ °C/Atm | |

| Operating range/range adjustability | 2% ~ 100% F.S / 50:1 | |

| Maximum measurable flow rate | 100% F.S (controllable) | |

| Typical response time | 200ms (adjustable) | |

| Monochrome LCD display | Simultaneously displays flow rate and settings | |

| Digital output signal | RS-485 / PROFIBUS | |

| Analog input/output signal | 0-5 Vdc / 4-20 mA | |

| Electrical signal interface | DB15 | |

| Supply voltage | ±15VDC, 24VDC | |

| Supply current | 0.250 Amp | 0.750 Amp |

| Operating temperature | +10~ +50℃ | |

| Maximum operating pressure | 1 MPa | |

| Installation method/direction requirements | Valveless | >1U/min range, valve must be installed vertically |

| Valve class | Normally Closed Valve | |

| Protection class | IP40 | |

| Material | Stainless Steel | |

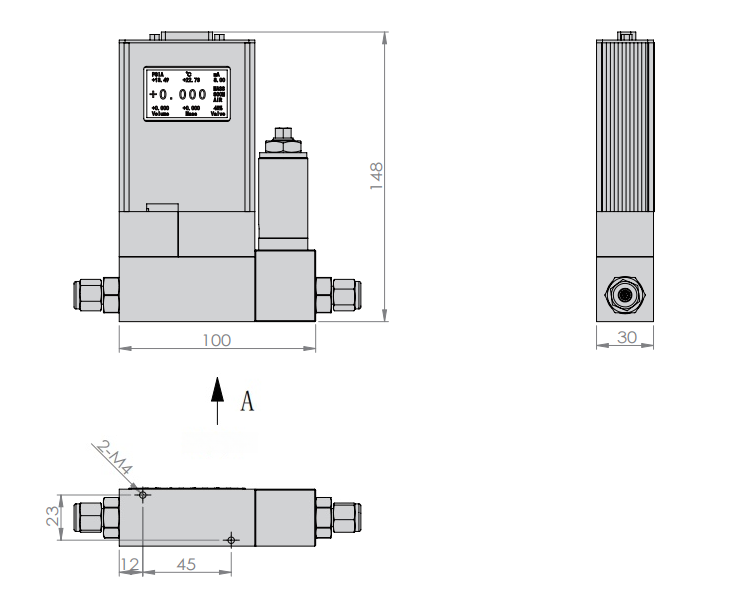

SI-10FC-L Low-Range Gas Mass Flow Controller Dimensions

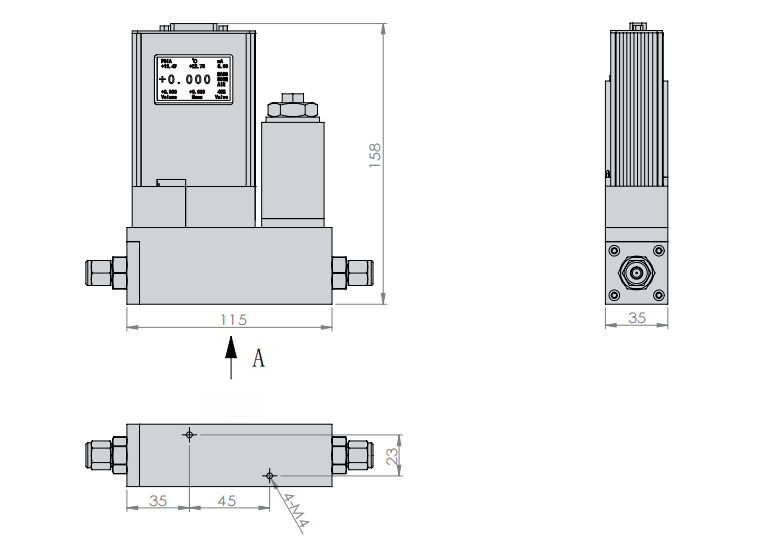

SI-10FC-L Low-Range Gas Mass Flow Controller Dimensions SI-10FC-M Medium-Range Gas Mass Flow Controller Dimensions

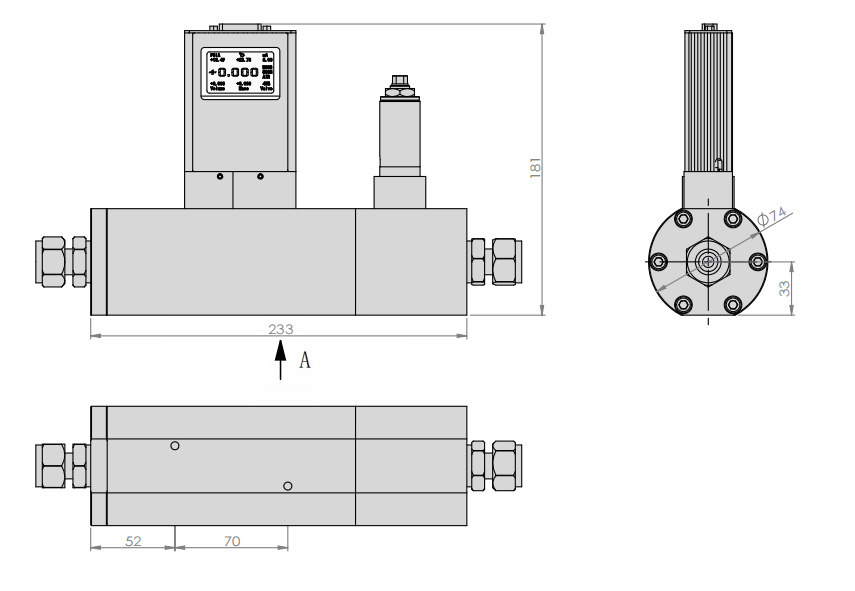

SI-10FC-M Medium-Range Gas Mass Flow Controller Dimensions SI-10FC-B High-Range Gas Mass Flow Controller Dimensions

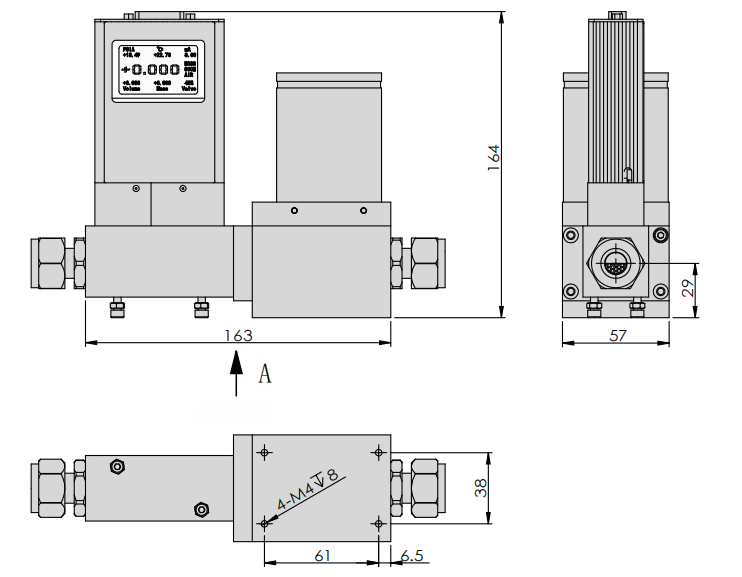

SI-10FC-B High-Range Gas Mass Flow Controller Dimensions SI-10FC-B Low Differential Pressure Flow Controller Valve

SI-10FC-B Low Differential Pressure Flow Controller Valve

Gas Mass Flow Controllers Applications

The SI-10FC series mass flow meters/controllers are widely used in various industries, such as process manufacturing, food analysis, analytical testing and measurement.

Multivariable measurement and a 50:1 adjustable range ratio allow a single SI-10FC gas flow meter and controller to replace the functionality of multiple devices.

1% accuracy, 1% repeatability, and a control response time of less than 200 milliseconds ensure the normal operation of process gases.

Semiconductor Industry Applications

In semiconductor manufacturing processes, mass flow controllers (MFCs) facilitate operations such as cleaning, vapor deposition, heat treatment, and etching. Examples include CVD, etching machines, and high-temperature furnaces.

Taking photolithography as an example, to ensure the quality and performance of semiconductor chips, gases such as hydrogen fluoride, nitrogen, and oxygen must be injected into the reaction chamber at precise flow rates. Each step is strictly controlled to ensure accurate exposure and etching.

In this process, the role of the MFC is particularly crucial, as even minute changes in gas flow can alter the material composition. For semiconductor processes, whether in high-temperature or high-vacuum environments, the MFC needs excellent temperature and pressure stability to ensure accuracy and reliability under various conditions.

Laminar Differential Pressure Mass Flow Controller Principle

Laminar differential pressure mass flow controllers are designed based on the law of conservation of mass, Bernoulli’s equation, and Hagen-Poiseuille’s law. They calculate the mass flow rate of a fluid by measuring the pressure difference across a pipe.

Laminar Flow Differential Pressure Principle: When a fluid flows in a pipe, the faster the fluid velocity, the lower the pressure. The laminar flow differential pressure mass flow controller utilizes this principle by installing two pressure sensors in the pipe to measure the pressure difference between its two ends.

Hagen-Poiseuille’s Law: Under constant parameters such as temperature and pipe diameter, when the gas is in a laminar flow state, the volumetric flow rate can be calculated by acquiring the pressure difference signal across the laminar flow element. Further corrections for temperature and pressure parameters can yield the standard volumetric flow rate.

Rectification Module: Laminar flow mass flow controllers typically include a rectification module. Its function is to convert irregular flow states such as turbulent or transitional flow into laminar flow, ensuring measurement accuracy.

Differential pressure sensor: Two pressure taps are located at the inlet and outlet of the laminar gas flow. A differential pressure sensor is positioned between these taps to acquire the pressure difference between the two taps. This pressure difference allows the determination of the gas velocity in laminar flow, thus providing the gas flow rate.

Technical Support

8 Best Mass Flow Controller Manufacturers

5 Best Digital Mass Flow Controllers for Precision Gas Flow Measurement

Guide to Connecting a Thermal Mass Flow Controller to a PLC

Expert Guide: How a Photoionization Detector Works

Unlike thermal flow meters, the SI-10FC Gas Mass Flow Controllers do not have an additional “specific heat capacity” error when using gas conversion coefficients. Therefore, even if the measured gas differs from the factory calibration gas, it will not affect the measurement accuracy.

The main application scenarios for Sino-Inst laminar flow gas mass flow controllers are in equipment and process production sites of high-end manufacturing industries, and also serve scientific and engineering research. In these application scenarios, the gas is mostly relatively clean, and the flow rate is in the small to medium range. Therefore, in the future process of global industrial chain upgrading and the continuous booming development of high-end manufacturing, laminar flow gas mass flow controllers/flow meters will become a very suitable choice.

Request a Quote

Related Products

SI-10FC Gas Mass Flow Controller with Laminar DP Technology

A gas mass flow controller (MFC) is an instrument used to accurately measure and control the mass flow rate of gases. An MFC not only functions as a mass flow meter, but more importantly, it automatically controls the gas flow rate. The user can set the flow rate as needed, and the MFC automatically maintains the flow rate at the set value. Even if system pressure fluctuates or ambient temperature changes, it will not deviate from the set value.

Product SKU: SI-10FC Gas Mass Flow Controller with Laminar Differential Pressure (DP) Technology

Product Brand: Sino-Inst

Price Valid Until: 2099-09-09

Product In-Stock: PreOrder

5

.png)