The SI-20FD high-accuracy mass flow controller boasts a measurement error of only ±0.5% of full scale, making it the preferred choice for measuring and controlling small flow rates of gas. It supports analog outputs of 0-5V, 4-20mA, and 1-5V, and digital outputs of RS232/485, MODBUS, and PROFIBUS protocols.

The superior accuracy of this series stems from its unique sensor probe. This sealed probe consists of two sensing elements: a velocity sensor and a temperature sensor. It automatically corrects for the effects of temperature and pressure changes.

★★★★★

Features

Specifications

| Technical Specifications | High-Accuracy Mass Flow Controller | High-Accuracy Mass Flow Meter |

| Measurement Range | 2SCCM~6000SLM | 2SCCM~6000SLM |

| Control Range | Controller Valve Control Range 50:1 | Flow Measurement Range Ratio 100:1 |

| Accuracy | ±0.5% F.S. (Full Scale) | |

| Linearity | ±0.25% F.S. | <0.1s |

| Repeatability | ±0.2% F.S. | |

| Response Time | <0.2s | <0.1s |

| Temperature Coefficient | ±0.025% F.S./℃ | |

| Operating Temperature | 0~50℃ | |

| Warm-up Time | 30S usable, reaches optimal state in 5Min | |

| Operating Pressure | Operating Differential Pressure: 0.1~0.5MPa Operating Pressure Drop: <0.01MPa | |

| Maximum Pressure Rating | 3MPa/10MPa | |

| Leak Rate | 1 × 10⁻⁹ Pa m³/s | |

| Mechanical Components | ||

| Base Material | Stainless Steel | |

| Connectors | φ8, φ10, φ12, Flange Mounting | |

| Seal Material | Fluorocarbon Rubber, Neoprene, Nitrile Rubber, Metal Seal | |

| Enclosure Protection Rating | IP40 | |

| Mounting Position | Horizontal Installation | |

| Electrical Performance | ||

| Electrical Connections | DB9 port, RJ11, 5.5×2.1 quick-connect power plug | |

| Display Status | With LCD display, without LCD display | |

| Digital Output | RS232/485, MODBUS protocol, PROFIBUS protocol | |

| Analog Output/Input | 0~5V, 4-20mA, 1~5V | |

| Power Supply | 24VDC, ±15VDC | |

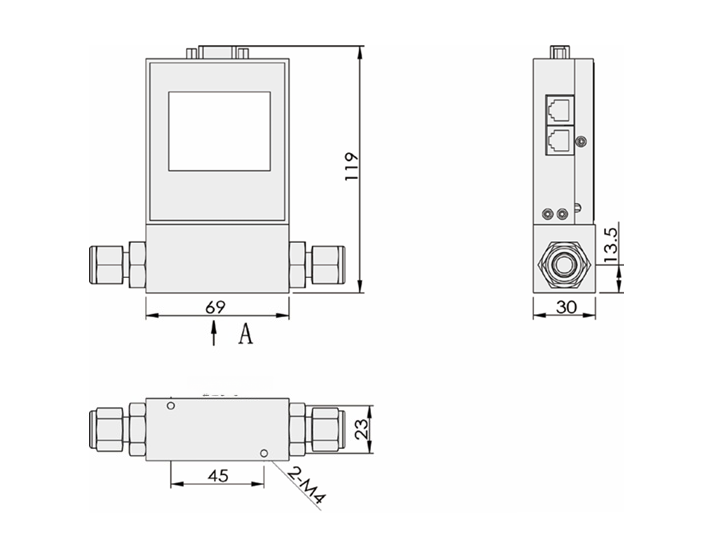

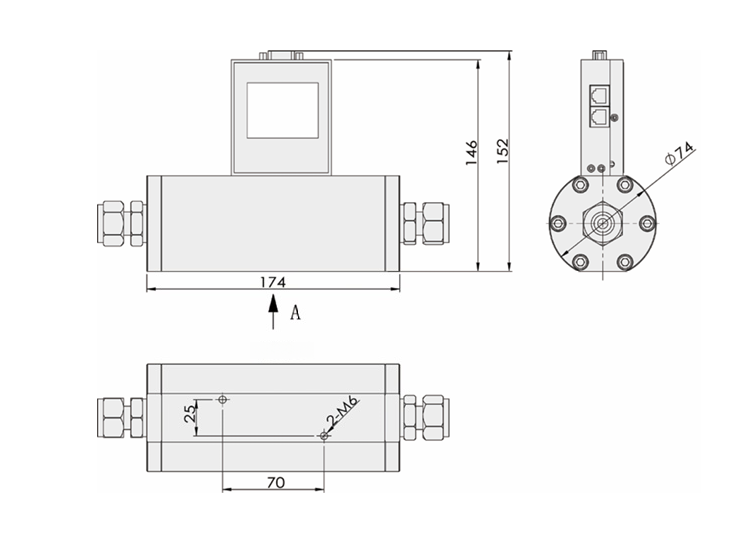

SI-20FD-LM High Accuracy Gas Mass Flow Meter Dimensions

SI-20FD-LM High Accuracy Gas Mass Flow Meter Dimensions SI-20FD-LC High Accuracy Gas Mass Flow Controller Dimensions

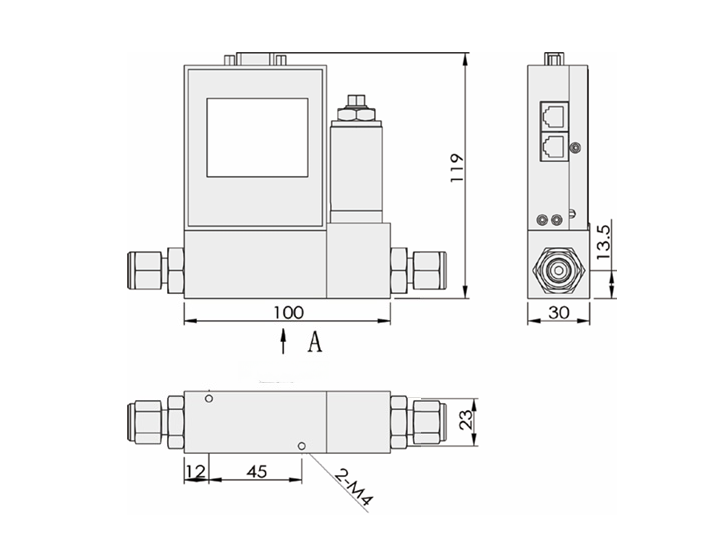

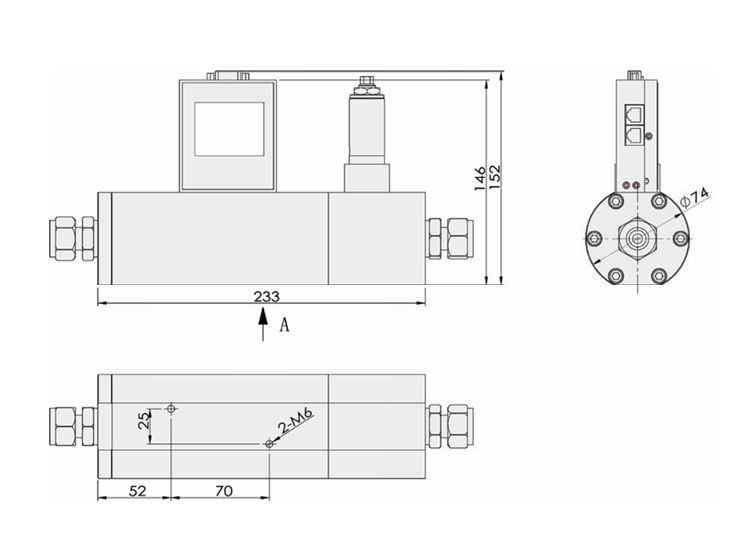

SI-20FD-LC High Accuracy Gas Mass Flow Controller Dimensions SI-20FD-MM High Accuracy Gas Mass Flow Meter Dimensions

SI-20FD-MM High Accuracy Gas Mass Flow Meter Dimensions SI-20FD-MC High Accuracy Gas Mass Flow Controller Dimensions

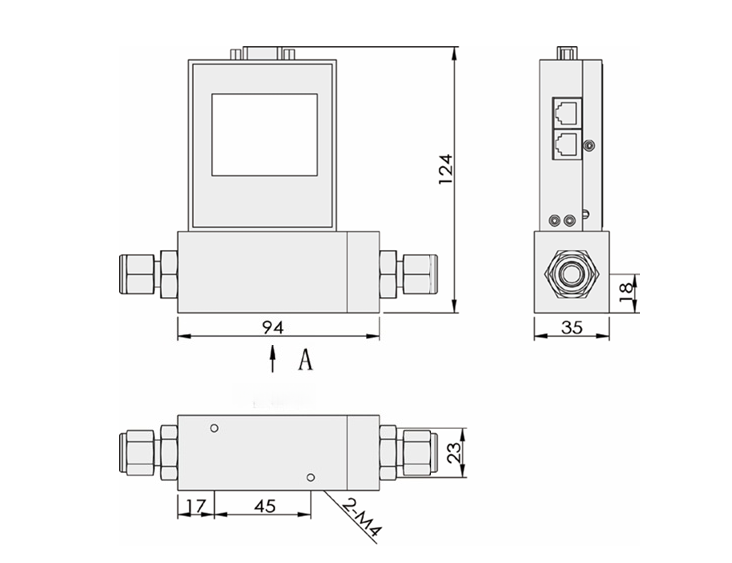

SI-20FD-MC High Accuracy Gas Mass Flow Controller Dimensions SI-20FD-BM High Accuracy Gas Mass Flow Meter Dimensions

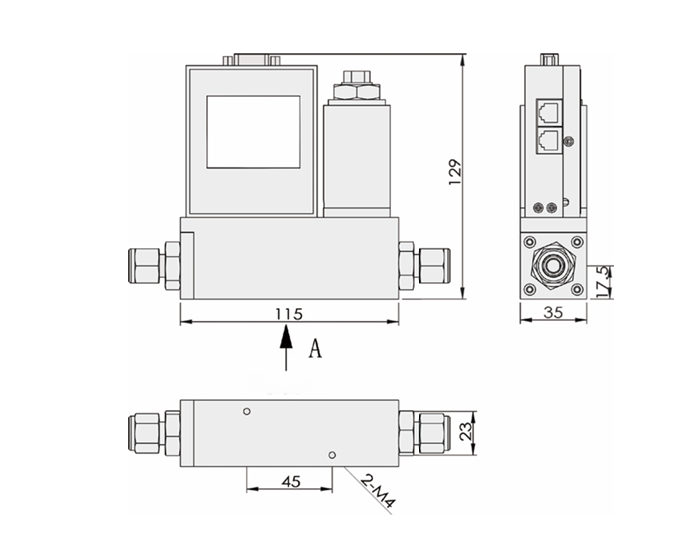

SI-20FD-BM High Accuracy Gas Mass Flow Meter Dimensions SI-20FD-BC High Accuracy Gas Mass Flow Controller Dimensions

SI-20FD-BC High Accuracy Gas Mass Flow Controller Dimensions

Model and measuring range:

| Controller | |||||

| Model | SI-20FD-LC | SI-20FD-MC | SI-20FD-BC | SI-20FD-HC | SI-20FDR-BC |

| Range | 2SCCM~30SLM | 30SLM~300SLM | 300SLM~3000SLM | 3000SLM~5000SLM | 1000SLM~3000SLM |

| Flowmeter | |||||

| Model | SI-20FD-LM | SI-20FD-MM | SI-20FD-BM | SI-20FD-HM | SI-20FDR-HC |

| Range | 2SCCM~30SLM | 30SLM~300SLM | 300SLM~3000SLM | 3000SLM~5000SLM | 4000SLM~6000SLM |

High Accuracy Gas Mass Flow Controller Working Principle

The SI-20FD is a high-accuracy series of flow meters/controllers with a measurement error of only ±0.5% of full scale. This series’ superior accuracy stems from its unique sensor probe. This sealed probe consists of two sensing elements—a velocity sensor and a temperature sensor—that automatically correct for the effects of temperature and pressure variations.

The SI-20FD High Accuracy Gas Mass Flow Controller circuit heats the velocity sensor to a constant value above the gas/liquid temperature. It then measures the cooling effect on the gas flow rate.

The flow rate is calculated based on the principle that the electrical power consumed to maintain a constant temperature difference is proportional to the gas mass flow rate. Both sensors are standard-grade platinum resistance temperature detectors (RTDs) sealed within a 316 stainless steel housing.

Laboratory and Industrial Environment Applications

The SI-20FD High Accuracy Gas Mass Flow Controller has a measurement error of ±0.5% of full scale, sufficient to meet the needs of most customers. It can be used for various experiments in laboratories as well as in complex industrial environments.

It plays an important role in research and production in various fields such as semiconductor and integrated circuit industries, special materials science, chemical industry, petroleum industry, pharmaceuticals, environmental protection, and vacuum systems.

Typical applications include:

Electronic process equipment, such as diffusion, epitaxy, CVD, oxidation, plasma etching, sputtering, and ion implantation; and coating equipment, fiber optic melting, microreactors, gas mixing systems, capillary measurement, gas chromatographs, and other analytical instruments.

To adapt to complex industrial environments, some models also support IP67 dust and water resistance and IICT4 intrinsically safe explosion protection. In addition to standard analog input/output interfaces, it also supports 485/232 interfaces, and the communication protocol is the standard Modbus RTU protocol.

Gas Conversion Coefficient Usage Instructions

Sino-Inst mass flow controllers and mass flow meters are generally calibrated with N2 at the factory. In actual use, if other gases are being used, reading correction may be necessary. This is done by multiplying the flow rate displayed on the flow meter by the flow conversion coefficient.

For single-component gases, the conversion coefficient can be found in the coefficient conversion table.

For a multi-component gas (assuming it consists of n gases), calculate its conversion using the following formula:

Coefficient C: Basic Formula: C = 0.3106N/ρ(Cp)

Where:

ρ—density of the gas under standard conditions

Cp—specific heat at isobaric pressure of the gas

N—molecular composition coefficient of the gas (related to the components of the gas molecules, see the table below)

| Gas Molecule Composition | For example | N values |

| Monoatomic Molecules | Ar He | 1.01 |

| Diatomic Molecules | CO N2 | 1.00 |

| Triaatomic Molecules | CO2 NO2 | 0.94 |

| Polyatomic Molecules | NH3 C4H8 | 0.88 |

For a gas mixture: N = N1(ω1/ωT) + N2(ω2/ωT) + … + Nn (ωn /ωT)

Where:

ω1…ωn—flow rate of the corresponding gas

ωT—flow rate of the gas mixture

ρ¹…ρn—density of the corresponding gas under standard conditions (values see the gas conversion coefficient table)

Cρ¹…Cρn—specific heat at isobaric pressure of the corresponding gas (values see the gas conversion coefficient table)

N1…Nn —These are the molecular composition coefficients for the corresponding gases; values can be found in the Gas Molecular Composition Coefficients Table.

Notes:

1) Standard conditions: Pressure—101325 Pa (760 mmHg), Temperature—273.15 K (0℃).

2) For parameters of gases not listed in the Gas Mass Flow Rate Conversion Coefficients Table, please consult Sino-Inst.

Gas Mass Flow Controller Gas Flow Conversion Factor

| Gases | Code | Specific heat (cal/g/°C) | Density (g/L 0°C) | Conversion factor |

| Air | 8 | 0.24 | 1.293 | 1.006 |

| Ar Argon | 4 | 0.125 | 1.7837 | 1.415 |

| AsH3 Arsenic hydride | 35 | 0.1168 | 3.478 | 0.673 |

| BBr3 Boron tribromide | 79 | 0.0647 | 11.18 | 0.378 |

| BCl3 Boron trichloride | 70 | 0.1217 | 5.227 | 0.43 |

| BF3 Boron trifluoride | 48 | 0.1779 | 3.025 | 0.508 |

| B2H6 Borane | 58 | 0.502 | 1.235 | 0.441 |

| CCl4 Carbon tetrachloride | 101 | 0.1297 | 6.86 | 0.307 |

| CF4 Carbon tetrafluoride | 63 | 0.1659 | 3.9636 | 0.42 |

| CH₄ Methane | 28 | 0.5318 | 0.715 | 0.719 |

| C₂H₂ Acetylene | 42 | 0.4049 | 1.162 | 0.581 |

| C₂H₄ Ethylene | 38 | 0.3658 | 1.251 | 0.598 |

| C₂H₆ Ethane | 54 | 0.4241 | 1.342 | 0.481 |

| C₃H₄ Propyne | 68 | 0.3633 | 1.787 | 0.421 |

| C₃H₆ Propene | 69 | 0.3659 | 1.877 | 0.398 |

| C₃H₈ Propane | 89 | 0.399 | 1.967 | 0.348 |

| C₄H₆ Butyne | 93 | 0.3515 | 2.413 | 0.322 |

| C₄H₈ Butene | 104 | 0.3723 | 2.503 | 0.294 |

| C₄H₁₀ Butane | 111 | 0.413 | 2.593 | 0.255 |

| C5H12 Pentane | 240 | 0.3916 | 3.219 | 0.217 |

| CH3OH Methanol | 176 | 0.3277 | 1.43 | 0.584 |

| C2H6O Ethanol | 136 | 0.3398 | 2.055 | 0.392 |

| C2H3Cl3 Trichloroethane | 112 | 0.1654 | 5.95 | 0.278 |

| CO Carbon monoxide | 9 | 0.2488 | 1.25 | 1 |

| CO2 Carbon dioxide | 25 | 0.2017 | 1.964 | 0.737 |

| C2N2 Cyanogen | 59 | 0.2608 | 2.322 | 0.452 |

| Cl2 Chlorine | 19 | 0.1145 | 3.163 | 0.858 |

| D2 Deuterium | 14 | 1.7325 | 0.1798 | 0.998 |

| F2 Fluorine | 18 | 0.197 | 1.695 | 0.931 |

| GeCl₄ Tetrachloride germanium | 113 | 0.1072 | 9.565 | 0.267 |

| GeH₄ Germanium hydride | 43 | 0.1405 | 3.418 | 0.569 |

| H₂ Hydrogen | 7 | 3.4224 | 0.0899 | 1.01 |

| HBr Hydrogen bromide | 10 | 0.0861 | 3.61 | 1 |

| HCl Hydrogen chloride | 11 | 0.1911 | 1.627 | 1 |

| HF Hydrogen fluoride | 12 | 0.3482 | 0.893 | 1 |

| HI Hydrogen iodide | 17 | 0.0545 | 5.707 | 0.999 |

| H₂S Hydrogen sulfide | 22 | 0.2278 | 1.52 | 0.844 |

| He Helium | 1 | 1.2418 | 0.1786 | 1.415 |

| Kr Krypton | 5 | 0.0593 | 3.739 | 1.415 |

| N₂ Nitrogen | 13 | 0.2468 | 1.25 | 1 |

| Ne Neon | 2 | 0.2464 | 0.9 | 1.415 |

| NH3 Ammonia | 29 | 0.5005 | 0.76 | 0.719 |

| NO Nitric oxide | 16 | 0.2378 | 1.339 | 0.976 |

| NO2 Nitrogen dioxide | 26 | 0.1923 | 2.052 | 0.741 |

| N2O Nitrous oxide | 27 | 0.2098 | 1.964 | 0.709 |

| O2 Oxygen | 15 | 0.2196 | 1.427 | 0.992 |

| PCl3 Phosphorus trichloride | 193 | 0.1247 | 6.127 | 0.358 |

| PH3 Phosphine | 31 | 0.261 | 1.517 | 0.691 |

| PF5 Phosphorus pentafluoride | 143 | 0.1611 | 5.62 | 0.302 |

| POCl3 Phosphorus oxychloride | 102 | 0.1324 | 6.845 | 0.302 |

| SiCl4 Silicon tetrachloride | 108 | 0.127 | 7.5847 | 0.284 |

| SiF₄ Silicon tetrafluoride | 88 | 0.1692 | 4.643 | 0.348 |

| SiH₄ Silane | 39 | 0.3189 | 1.433 | 0.599 |

| SiH₂Cl₂ Dichlorosilane | 67 | 0.1472 | 4.506 | 0.412 |

| SiHCl₃ Trichlorosilane | 147 | 0.1332 | 6.043 | 0.34 |

| SF₆ Sulfur hexafluoride | 110 | 0.1588 | 6.516 | 0.264 |

| SO₂ Sulfur dioxide | 32 | 0.1489 | 2.858 | 0.687 |

| TiCl₄ Titanium tetrachloride | 114 | 0.1572 | 8.465 | 0.206 |

| WF₆ Tungsten hexafluoride | 121 | 0.0956 | 13.29 | 0.215 |

| Xe Xenon | 6 | 0.0397 | 5.858 | 1.415 |

Technical Support

Expert Guide: How a Photoionization Detector Works

Sino-Inst specializes in manufacturing gas/liquid mass flow meters and controllers. Designed according to customers’ specific operating conditions and needs, our products are widely used in various industries for the precise measurement and control of gas/liquid mass flow rates.

They play a vital role in research and production in numerous fields, including the semiconductor and integrated circuit industry, specialty materials science, chemical industry, petroleum industry, pharmaceuticals, environmental protection, and vacuum systems. If you require a customized High Accuracy Gas Mass Flow Controller, please feel free to contact our sales engineers!

Request a Quote

SI-20FD High Accuracy Gas Mass Flow Controller | Sino-Inst

The SI-20FD High Accuracy Gas Mass Flow Controller circuit heats the velocity sensor to a constant value above the gas/liquid temperature. It then measures the cooling effect on the gas flow rate.

Product SKU: SI-20FD

Product Brand: Sino-Inst

Product In-Stock: InStock

.png)