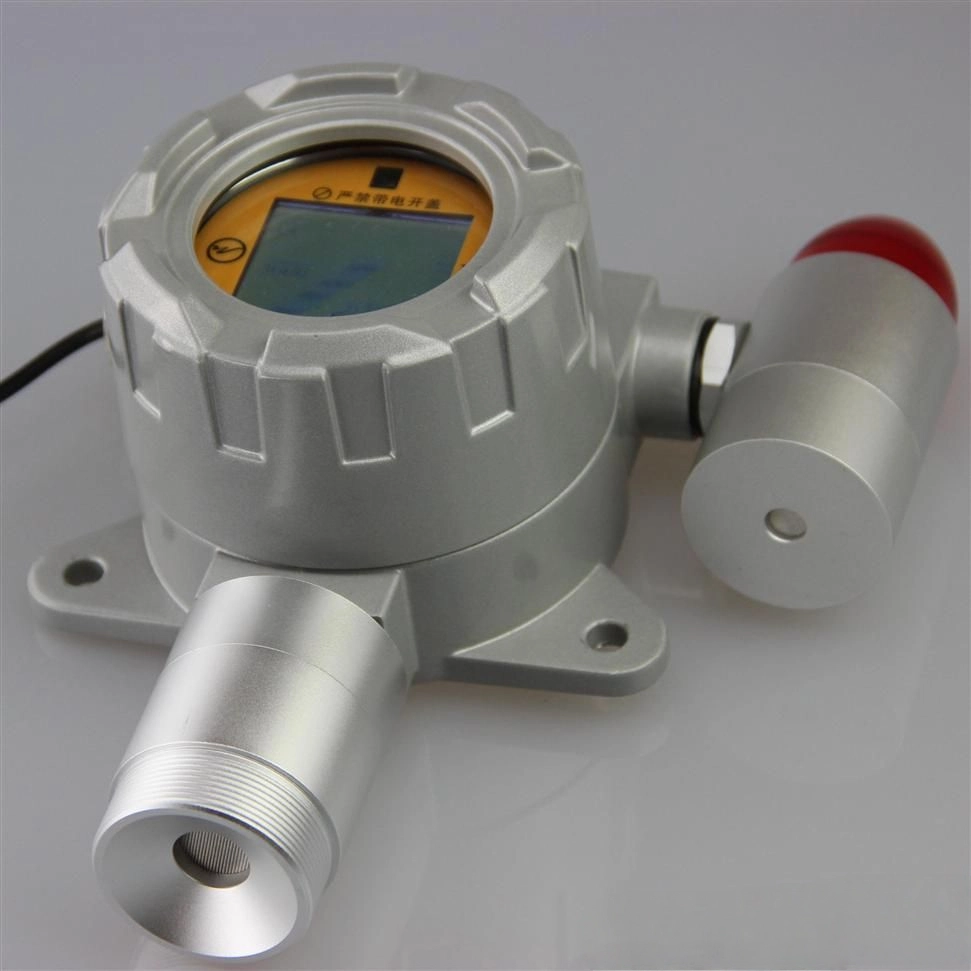

Fixed VOC monitors are suitable for continuous online detection and alarm of volatile organic compound (VOC) gases in workshops, enclosed work areas, and around equipment. The robust and durable explosion-proof enclosure is suitable for various hazardous locations and harsh industrial environments.

VOCs, or Volatile Organic Compounds, are a class of organic compounds that readily evaporate at room temperature. They are composed of carbon (C) and hydrogen (H) elements and can originate from various chemical substances, including solvents, fuels, paints, and cleaning agents. Common examples include benzene, formaldehyde, xylene, and ethanol. Due to their volatility, they can rapidly convert to gas at room temperature and disperse into the surrounding air.

★★★★★

Features

Specifications

| Measurable Gases | VOCs (Parameters can be customized; other gases can also be customized, see gas appendix) | ||||

| Measuring range and resolution | VOC: 0-100ppm, 0.01ppm, imported high-precision electrochemical principle sensor or VOC: 0-100%LEL, 0.1%LEL, industrial-grade catalytic combustion principle sensor or VOC: 0-10ppm, 0.01ppm, imported high-precision PID photoionization principle sensor Refer to the attached table; other ranges, principles, and resolutions can be customized. | ||||

| Detection accuracy | ≤±3%F.S (Higher precision can be customized) | ||||

| Linearity | ≤±2% | Repeatability | ≤±2% | Uncertainty | ≤±2% |

| Response time | T90≤30 seconds | Recovery time | ≤30秒 | ||

| Signal Output | Bus-based RS485 (RTU), three-wire 4~20mA, relay (passive or active output) | ||||

| Optional: 0~20mA, 1~5V, 0~5V, 0~10V, wireless transmission, network transmission, SMS alarm. | |||||

| Operating Environment | Temperature: -40℃~+70℃, Humidity: ≤95%RH (standard) for non-condensing environments. | ||||

| For use in condensing environments, customization is required or the operating environment must be specified when ordering. | |||||

| Display method | 1.7-inch high-definition color screen with a resolution of 320×240; optional: high-brightness LED display. | ||||

| Operating voltage | 12~36V (DC), standard power supply for a single unit is 24V, 1A or greater DC switching power supply or regulated power supply; | ||||

| Operating mode | Fixed installation, online detection, diffusion measurement; optional pipeline type, flow-through type, and pump-suction type measurement. | ||||

| Installation method | Pipeline type, wall-mounted type. The working pressure of the pipeline type is atmospheric pressure ±30%; pressure reduction is required for pressure exceeding this range. | ||||

| Alarm Method | Default 1 channel, optional 2 channels of passive contact (dry contact) output, alarm points can be set. | ||||

| Optional integrated or split-type audible and visual alarm. | |||||

| Electrical Interface | 3/4NPT, optional 1/2NPT, M20X1.5. | ||||

| Connecting Cable | Three-wire system 4~20mA, select three-core shielded cable; RS485, select four-core; shielding layer grounded. | ||||

| Protection Class | IP65 | ||||

| Explosion-proof Type | Explosion-proof type. | ||||

| Explosion-proof Mark | ExdⅡCT6Gb | ||||

| Dimensions | 230×210×90mm (L×H×W) with light; 230×152×90mm (L×H×W) without light. | ||||

| Weight | 1600g | ||||

| Standard Accessories | Instruction manual, certificate of conformity, outer packaging box; | ||||

| Optional Accessories | Integrated sound and light alarm, split sound and light alarm, 24V DC regulated power supply; | ||||

| Accessories for computer monitoring: free host computer software, RS485/RS232 converter, laptops without RS232 interface also need USB/RS232 conversion cable, and if network transmission is required, a TCP/IP converter is also needed. | |||||

| Wireless transmission (optional) | Data can be wirelessly transmitted to mobile phones, remote monitoring centers, monitoring computers, and other monitoring equipment. The host computer can then perform data analysis, storage, and printing functions. | ||||

| Preprocessing (optional) | Normal temperature and high humidity pretreatment systems, high temperature and high humidity pretreatment systems, and high temperature, high humidity, and high dust pretreatment systems. | ||||

| Mounting accessories | Optional accessories: Wall-mounted brackets, pipe mounting clips (1/4″ and 1/6″ inch pipes). | ||||

| Stainless steel threaded weld bead or flange for pipe mounting (pipe or flange size must be specified, such as DN50, DN15, etc.), | |||||

| Rain cover, 24VDC or 220AC sampling pump (sampling distance 10 meters), vacuum pump (sampling distance greater than 40 meters) | |||||

| 24V switching power supply, pressure reducing valve, flow meter. | |||||

| Applications | Suitable for all applications requiring fixed installation and online monitoring of gas concentration, including gas, oil, petrochemical, oil field, oil depot, chemical, metallurgical, and coking plants. | ||||

Commonly Detected Gases

| Model | Detected Gases: | Model | Detected Gases: | Model | Detected Gases: |

| EX | Combustible Gas (EX) | M3 | Methane (CH4) | O2 | Oxygen (O2) |

| C1 | Carbon Monoxide (CO) | C2 | Carbon dioxide (CO2) | Q1 | Formaldehyde (CH2O) |

| O3 | Ozone (O3) | Y2 | Hydrogen sulfide (H2S) | S2 | Sulfur dioxide (SO2) |

| L3 | Chlorine (Cl2) | N3 | Ammonia (NH3) | H1 | Hydrogen (H2) |

| HZ3 | Hydrogen Cyanide (HCN) | PX3 | Phosphine (PH3) | CX3 | Chlorine dioxide (CLO2) |

| E1 | Ethylene Oxide (ETO) | TX3 | Phosgene (COCl2) | SH4 | Silane (SiH4) |

| F2 | Fluorine (F2) | FX2 | Hydrogen fluoride (HF) | SX3 | Sulphoyl fluoride (SO2F2) |

| HE | Helium (He) | VOC | VOC/TVOC | FX1 | Hydrogen bromide (HBr) |

| B2 | Diborane (B2H6) | AX3 | Arsine (AsH3) | G3 | Germanane (GeH4) |

| NH2 | Hydrazine, Hydrazine (N2H4) | P2 | Tetrahydrothiophene (THT) | R2 | Bromine (Br2) |

| G2 | Acetylene (C2H2) | C5 | Ethylene (C2H4) | Q4 | Acetaldehyde |

| E5 | Ethanol (C2H6O) | E4 | Methanol (CH4O) | CS2 | Carbon disulfide (CS2) |

| FX3 | Acrylonitrile | TP1 | Methylamine | N2 | Nitrogen (N2) |

| I2 | Iodine (I2) | N4 | Nitrogen oxides (NOx) | CX6 | Benzene (C6H6) |

| CX7 | Toluene (C7H8) | CX8 | Xylene (C8H10) | CT | Styrene (C8H8) |

| LX4 | Vinyl Chloride (C2H3Cl) | CH3 | Mbromomethane (CH3Br) |

Note: For other gases not listed in the table above, please call for inquiries.

Technical Support

7 Critical Mistakes in Gas Sampling System Design: A Practical Checklist

Buyer’s Guide: 7 Critical Checks for Selecting a Chlorine Gas Detector

Proven Solutions for the 5 Critical Health Dangers of Ammonia Leaks

An Expert 7-Point Checklist for Industrial Gas Detection Systems

Buyer’s Guide for Ammonia Gas Monitor

VOCs (Volatile Organic Compounds) are widely present in residential and industrial environments. The photochemical smog they form in the atmosphere is largely carcinogenic, teratogenic, and mutagenic, posing significant threats to the environment and human health.

Many countries have enacted laws to restrict VOC emissions and have included VOCs in their monitoring programs. The United States’ automatic photochemical smog monitoring system includes 56 VOCs, while Europe has listed more than 30.

Online VOC monitoring equipment and technologies vary widely. In practice, monitoring and analysis systems differ significantly across industries, directly impacting the accuracy of monitoring data. In the future, VOC detection will evolve towards faster, more accurate, and more convenient methods. Technological innovation will continuously improve detection sensitivity and accuracy, and the application areas will continue to expand and deepen.

Request a Quote

.png)