Multi-gas detectors simultaneously measure multiple gases, typically including oxygen (O₂), combustible gases (LEL), carbon monoxide (CO), and hydrogen sulfide (H₂S), which are common threats in industrial environments and confined spaces.

Common multi-gas detectors include portable and fixed types. They utilize various gas sensor technologies, such as electrochemical, catalytic beads, and infrared, each with its own unique advantages. Based on our years of experience at Sino-Inst, we explain the differences between portable devices (used for personal protection and confined space entry) and fixed systems (for continuous area monitoring). We hope to provide a comprehensive guide for safety professionals, industrial experts, and workers, fostering a deeper understanding of these life-saving technologies and promoting their effective implementation.

The Foundational Need for Gas Detection

In many industrial and occupational settings, from the cavernous holds of a cargo ship to the intricate pipework of a chemical plant, the atmosphere cannot be taken for granted. Processes that are fundamental to our modern economy—refining, manufacturing, energy production, and waste treatment—can release gases that are toxic, that can displace life-sustaining oxygen, or that can accumulate to create a potent risk of fire or explosion.

The human senses, for all their marvelous adaptability, are tragically ill-equipped to perceive these dangers. Carbon monoxide is odorless and colorless. An oxygen-deficient atmosphere provides no warning before inducing disorientation and unconsciousness. The “rotten egg” smell of hydrogen sulfide can deaden the olfactory nerve at high concentrations, creating a false sense of security just as the danger becomes most acute.

A single-gas monitor is a valuable tool when a specific, known threat is the only concern. However, the reality of many hazardous environments is far more complex. A leak in one pipe might release a toxic substance, while a nearby process could simultaneously be consuming oxygen. It is this potential for compound, overlapping hazards that elevates the necessity of multi gas detectors.

These instruments are not merely a convenience; they are a direct response to the multifaceted nature of atmospheric risk. They embody a principle of comprehensive vigilance, standing guard against a roster of potential threats simultaneously. Whether it is a compact, belt-worn portable multi gas detector carried by a worker into a sewer line or a robust, wall-mounted fixed multi gas detector watching over a compressor station, the purpose is the same: to provide an unwavering, early warning before a hazardous condition can escalate into a tragedy.

Understanding these tools, therefore, is not just a technical exercise; it is an essential competency for anyone responsible for the safety of others in the modern industrial landscape.

1. The Heart of the Matter: Understanding Target Gases and Sensor Technology

The journey toward selecting the right safety instrument begins not with the device itself, but with a thoughtful and rigorous assessment of the dangers it is meant to detect. A multi gas detector is, at its core, a vessel for its sensors. The quality, type, and appropriateness of those sensors are the primary determinants of the device’s efficacy.

The most common configuration for multi gas detectors, particularly those used for confined space entry, is the “standard four-gas” setup. This combination is prevalent for a reason: it addresses the most common and immediate atmospheric killers.

- Oxygen (O₂): Monitoring for both deficiency and enrichment. An environment is typically considered oxygen-deficient below 19.5% by volume and oxygen-enriched above 23.5%. Deficiency can lead to asphyxiation, while enrichment dramatically increases the risk and intensity of a fire.

- Combustible Gases: Measured as a percentage of the Lower Explosive Limit (%LEL). The LEL is the minimum concentration of a gas in air that can propagate a flame. A reading of 10% LEL, for instance, means the atmosphere contains 10% of the concentration needed to potentially ignite.

- Carbon Monoxide (CO): A toxic gas produced by incomplete combustion. It is a chemical asphyxiant that interferes with the blood’s ability to carry oxygen.

- Hydrogen Sulfide (H₂S): A highly toxic gas common in industries like oil and gas, pulp and paper, and wastewater treatment. It is immediately dangerous to life and health at relatively low concentrations.

While this four-gas combination is a powerful baseline, it is crucial to resist the temptation to see it as a universal solution. Your specific application may demand a different suite of sensors. A facility using ammonia for refrigeration needs an ammonia sensor. A team working near sources of chlorine requires a chlorine sensor. The process of hazard assessment is non-negotiable and forms the bedrock of a sound gas detection program.

Common Sensor Technologies

Once you have identified your target gases, the next step is to understand the technologies used to detect them. Different sensors operate on different principles, each with inherent strengths and weaknesses.

A sophisticated user does not just ask if a device detects a gas, but how it detects it. This knowledge is vital for understanding potential interferences, maintenance requirements, and the overall reliability of the readings. The National Institute for Occupational Safety and Health (NIOSH) emphasizes the importance of knowing your equipment to correctly interpret its readings.

| Sensor Type | Operating Principle | Common Applications | Advantages | Disadvantages |

| Electrochemical (EC) | Target gas reacts with an electrode, generating a small electrical current proportional to the gas concentration. | Toxic gases (CO, H₂S, Cl₂, NH₃), Oxygen (O₂) | High sensitivity, low power consumption, compact size. | Limited lifespan (2-3 years), susceptible to cross-interference from other gases, can be affected by extreme temperatures and humidity. |

| Catalytic Bead (Pellistor) | Gas burns on the surface of a heated catalyst-coated bead, changing its electrical resistance. | Combustible gases (%LEL) | Robust, proven technology, relatively low cost. | Requires oxygen to operate, can be “poisoned” by silicones, lead, and sulfur compounds, high power consumption. |

| Infrared (IR) | Target gas absorbs infrared light at a specific wavelength; the amount of absorption is proportional to the concentration. | Combustible gases (%LEL), Carbon Dioxide (CO₂) | Long lifespan (5+ years), not poisoned by contaminants, can operate in low-oxygen environments. | Higher initial cost, cannot detect hydrogen (H₂), performance can be affected by condensation. |

| Photoionization (PID) | High-energy ultraviolet light ionizes volatile organic compounds (VOCs); the detector measures the resulting electrical current. | Broad-range VOCs (e.g., benzene, solvents) | Detects a wide range of compounds at very low (ppm/ppb) levels, non-destructive. | Non-specific (reports a total concentration), high humidity can affect readings, lamp requires regular cleaning/replacement. |

The Nuances of Sensor Selection

Choosing between these technologies involves a series of trade-offs. Consider the combustible gas sensor. For decades, the catalytic bead was the standard. It is reliable and cost-effective.

However, imagine you are working in an environment where you might need to inert a tank with nitrogen before entry. A catalytic bead sensor, which requires at least 10-15% oxygen to function, would be completely blind in this scenario. It would show a reading of 0% LEL not because the atmosphere is safe, but because the sensor itself cannot operate. In this case, an infrared (IR) sensor, which does not require oxygen, is the only viable choice.

The IR sensor’s immunity to poisons is another significant advantage in industrial settings where silicones or other contaminants might be present. While its initial cost is higher, its longer life and greater reliability can result in a lower total cost of ownership, a concept we will explore in greater depth later.

Similarly, the rise of Photoionization Detectors (PIDs) has been transformative for applications involving toxic volatile organic compounds (VOCs). Standard four-gas multi gas detectors would be completely unaware of a hazardous concentration of benzene, for example. A PID-equipped monitor can be configured to detect hundreds of different VOCs, providing a crucial layer of protection for workers in refineries, chemical plants, and hazardous material response. However, this power comes with a responsibility to understand its limitations.

A PID is generally non-specific; it reports a total concentration of all ionizable compounds. Interpreting its readings requires skill and an understanding of the potential substances present. Recent advancements in sensor technologies, such as photo-activated chemical sensors, continue to push the boundaries of sensitivity and specificity, promising even more capable detection in the future.

Ultimately, the first and most critical factor in your selection process is to match the sensor technology within the multi gas detector to the specific and potential atmospheric hazards of your workplace. This requires a thoughtful analysis of your processes, materials, and environments.

2. Assessing the Environment for Portable vs. Fixed Multi Gas Detectors

After determining what you need to detect, the next essential question is where and how you need to detect it. The physical nature of your worksite and the tasks being performed will dictate the appropriate form factor for your gas detection solution. The world of multi gas detectors is broadly divided into two families: portable and fixed. This is not a question of which is “better” in the abstract, but which is the correct tool for the job at hand.

A portable multi gas detector is a personal safety device. It is designed to move with the worker, creating a personal, mobile safety zone. Think of it as a vigilant companion, constantly sampling the air in the user’s immediate breathing zone. Its purpose is to warn that individual of a hazard they are walking into or that is developing around them.

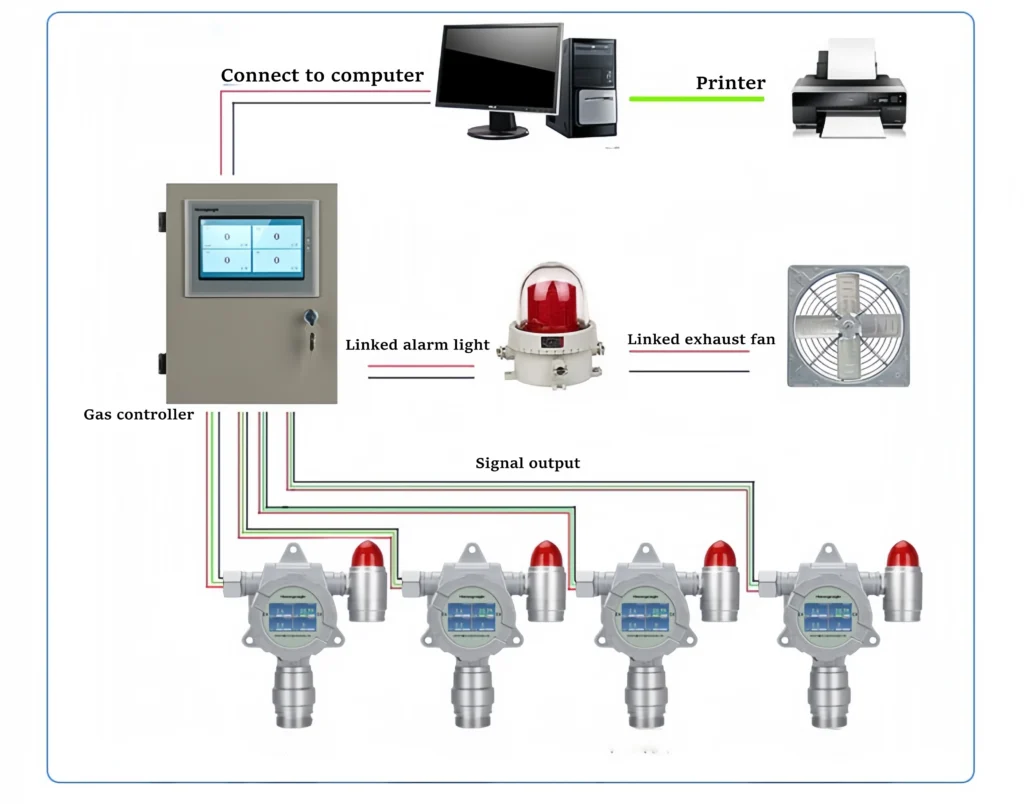

Conversely, a fixed multi gas detector is an area monitor. It is permanently installed in a location where there is a high or persistent risk of a gas leak. Its purpose is to act as a sentinel for a specific piece of equipment or a larger area, providing an early warning to everyone in the vicinity and often triggering automated responses like activating ventilation fans or initiating a shutdown procedure.

The Domain of the Portable Multi Gas Detector

The quintessential application for a portable multi gas detector is confined space entry. A confined space—such as a tank, vault, sewer, or pipeline—is defined by its limited entry and exit and is not designed for continuous occupancy. These spaces are notorious for atmospheric hazards, which can develop rapidly and without warning.

Before a worker enters such a space, regulations and best practices worldwide mandate that the atmosphere be tested from the outside. This is typically done using a portable multi gas detector equipped with a pump and a length of tubing. The probe is lowered into the space, and the operator tests the atmosphere at various levels—top, middle, and bottom—because different gases have different densities and may stratify. Methane, for example, is lighter than air and will collect at the top, while hydrogen sulfide is heavier and will sink to the bottom.

Once the space is deemed safe for entry, the worker keeps the personal multi gas detector for confined space with them at all times. This is not redundant. Conditions inside a confined space can change in An instantaneous release of trapped gas could disrupt a pocket, a chemical reaction could begin, or contaminants could leak in from an adjacent area.

Sino-Inst’s portable gas detectors are compact, rugged, and feature clear alarms. These devices can be worn without getting in the way of work, withstand the inevitable bumps and drops of industrial environments, and attract attention with a loud alarm, bright flashing light, and strong vibration.

The Realm of the Fixed Multi Gas Detector

A fixed multi gas detector is the appropriate choice when the location of a potential gas leak is predictable. Consider a battery charging room in a warehouse. The charging process for lead-acid batteries can release hydrogen gas, which is highly flammable. While the ventilation system is designed to prevent accumulation, a failure in that system could lead to a dangerous buildup.

Installing a fixed gas detection system set to alarm at 10% LEL of hydrogen provides a continuous, automated layer of protection. It doesn’t rely on a person remembering to bring a portable monitor into the room. The detector is always on, always watching.

Other classic applications for a fixed multi gas detector include:

- Around compressors, pumps, or valves in a natural gas facility.

- In chemical storage rooms.

- Near boilers or large combustion sources to monitor for CO.

- In underground parking garages to control ventilation based on CO levels.

- Perimeter monitoring around a process unit to provide an early warning of a leak to the surrounding plant.

These systems are often more complex than their portable counterparts. They require a stable power source and their outputs are typically wired to a central controller. This controller can be programmed to take specific actions when an alarm is triggered: sounding a plant-wide siren, closing a valve, starting an emergency fan, or notifying the control room. This automated response capability is a key advantage of fixed systems, removing the element of human reaction time from the initial stages of an incident.

Two Systems: Making the Choice

The following table provides a structured comparison to aid in the decision-making process. It is not an exhaustive list, but it captures the core philosophical and practical differences between the two approaches.

| Attribute | Portable Multi Gas Detector | Fixed Multi Gas Detector |

| Primary Purpose | Personal protection, mobile monitoring, spot checks. | Continuous area monitoring, asset protection, process control. |

| Mobility | High. Worn or carried by the user. | None. Permanently installed. |

| Typical Application | Confined space entry, leak investigation, personal safety in variable environments. | Monitoring specific leak sources (e.g., valves, pumps), perimeter monitoring, protecting entire rooms or buildings. |

| Power Source | Rechargeable or disposable batteries. | Hard-wired AC or DC power. |

| Alarm Response | Alerts the individual user via audible, visual, and vibratory alarms. | Alerts a wide area via horns/strobes; can trigger automated system shutdowns, ventilation, or other controls. |

| Data Management | Datalogging for incident review and compliance; often managed via docking stations. | Continuous data feed to a central controller or plant-wide SCADA system. |

| Maintenance | User performs daily bump tests; periodic calibration via docking station or manually. | Scheduled in-situ calibration by trained technicians. |

In many facilities, the answer is not to choose one type over the other, but to implement a hybrid system. A fixed multi gas detector system might provide the primary line of defense around a known hazard, while workers entering that area also carry a portable multi gas detector as a secondary, personal layer of protection. This defense-in-depth strategy is a hallmark of a mature safety culture, acknowledging that no single solution is infallible. The choice and placement of these devices should be guided by a thorough risk assessment that considers both the predictable and the unpredictable elements of the work being performed.

3. Evaluating Durability, Ingress Protection (IP), and Certifications

A multi gas detector is a piece of safety equipment, and in the environments where it is most needed, it will be subjected to conditions that are far from gentle. It will be dropped, splashed with water, covered in dust, and exposed to extreme temperatures. A device that fails under these predictable stresses is not just an inconvenience; it is a liability. Therefore, a critical part of the selection process involves moving beyond the sensor specifications and scrutinizing the physical integrity and certified resilience of the instrument itself.

Drop Tests and Ingress Protection

Imagine a maintenance technician climbing a ladder to work on an overhead valve. Her portable multi gas detector snags on a piece of scaffolding and falls 20 feet to the concrete floor below. What happens next is a moment of truth. Does the housing crack? Does the display go blank? Do the sensors get dislodged, rendering the device useless?

Leading manufacturers understand these scenarios and design their instruments accordingly. They perform rigorous drop tests, often from heights far greater than what might be expected in normal use, to ensure the internal components are sufficiently shock-mounted and the external housing can absorb the impact. When evaluating a portable multi gas detector, look for a specified drop-test height. A rating of 20 or 25 feet (around 6-7.5 meters) onto concrete indicates a truly robust design.

Equally important is the device’s ability to resist the ingress of dust and water. This is quantified by the Ingress Protection (IP) rating, a standardized system defined by the International Electrotechnical Commission (IEC). An IP rating consists of two digits.

- The first digit (0-6) rates the protection against solid objects, from large body parts down to microscopic dust. A rating of 6 indicates the device is completely “dust-tight.”

- The second digit (0-9) rates the protection against liquids, from dripping water to high-pressure jets and complete submersion.

For a portable multi gas detector used in industrial settings, a rating of IP67 or IP68 is the effective standard in 2025.

- IP67 means the device is dust-tight (6) and can withstand immersion in water up to 1 meter deep for 30 minutes (7).

- IP68 means the device is dust-tight (6) and can withstand continuous immersion in water under conditions specified by the manufacturer (e.g., 2 meters for 1 hour) (8).

Why does this matter? A worker in a wastewater treatment plant might be splashed with water. A miner works in a perpetually dusty and damp environment. A technician cleaning a tank might need to rinse off their equipment at the end of the day. An IP67 or IP68 rating provides the assurance that these everyday events will not compromise the life-saving function of the detector. For a fixed multi gas detector installed outdoors or in a wash-down area, a high IP rating is just as critical.

Understanding Hazardous Location Certifications

Perhaps the most complex but most important aspect of a detector’s physical qualifications is its certification for use in hazardous locations. In areas where flammable gases, vapors, or dusts may be present, any piece of electrical equipment—including a multi gas detector—is a potential ignition source. A stray spark from its internal circuitry could be catastrophic. To prevent this, detectors intended for these environments must be “intrinsically safe” or “explosion-proof.” These are not marketing terms; they are precise engineering classifications certified by independent third-party agencies.

The certification landscape can be confusing because different regions of the world use different systems, though they are largely harmonized today.

- North America (USA & Canada): Certifications are typically from organizations like UL (Underwriters Laboratories), CSA (Canadian Standards Association), or FM (FM Approvals). The standards classify hazardous locations by Class (substance type: I for gases/vapors, II for dusts), Division (hazard presence: 1 for normally present, 2 for abnormally present), and Group (substance characteristic: A, B, C, D for gases; E, F, G for dusts).

- Europe: The ATEX Directives are mandatory. Locations are classified into Zones (0, 1, 2 for gases; 20, 21, 22 for dusts) based on the frequency and duration of the hazardous atmosphere’s presence. Equipment is categorized based on the level of protection it provides.

- International: The IECEx system is a global framework intended to harmonize standards worldwide. It is very similar in its approach to ATEX and is widely accepted in many countries, including Australia, and is often seen alongside local certifications elsewhere.

What does this mean for you as a buyer? You must ensure that the multi gas detector you choose carries the correct certification for the specific hazardous location where it will be used. Using a non-certified device in a Zone 1 or Class I, Division 1 area is a serious safety violation and an unacceptable risk. The certification markings on the device label are not just a collection of letters and numbers; they are a legal and ethical declaration that the device has been designed, tested, and proven not to become an ignition source in a flammable atmosphere.

For example, a marking like “Class I, Division 1, Groups A, B, C, D, T4” tells a trained user exactly where that device can be safely operated. It is a language of safety that must be understood and respected. A quality instrument like a versatile multi-hazard gas monitor will have these certifications clearly listed in its specifications, providing the necessary assurance for deployment in regulated environments.

When you select a detector, you are placing your trust in its design. That trust must be earned not only through its ability to detect gas but also through its proven ability to survive the rigors of the job and to operate safely even when surrounded by the very hazards it is designed to monitor.

4. Data Logging, Connectivity, and Fleet Management

In previous eras, a multi gas detector was a self-contained unit. It sounded an alarm, the worker reacted, and the event itself, unless manually logged, would vanish into memory. The data—the rich tapestry of exposure levels, alarm times, and atmospheric trends—was largely ephemeral. The evolution of microelectronics and wireless communication has fundamentally changed this paradigm. By 2025, the expectation is that these devices are not just alarms, but data-gathering instruments that are part of a larger safety ecosystem. This connectivity transforms them from simple personal protective equipment into powerful tools for risk management, compliance, and behavioral safety.

The Importance of Datalogging

At its most basic level, nearly every modern multi gas detector has an onboard memory for datalogging. It continuously records atmospheric conditions, typically at intervals of one minute or less. It also logs discrete events, such as alarms, bump tests, and calibrations. This data is a treasure trove of information, and its value extends far beyond the individual user.

Imagine a worker experiences a CO alarm in a particular area of the plant. After ensuring the worker is safe, a safety manager can download the data from their portable multi gas detector. The log might show not a sudden spike, but a gradual increase in CO levels over a 30-minute period. This suggests a slow leak, not a catastrophic failure. Cross-referencing this with data from other workers’ detectors might help pinpoint the source.

For compliance purposes, datalogging is indispensable. Regulations in many jurisdictions require that all confined space entry atmospheric test results be recorded. Datalogging automates this process, creating an irrefutable, time-stamped record of pre-entry checks. This protects both the workers, by enforcing procedure, and the company, by demonstrating due diligence in the event of an audit or incident investigation.

The Power of Real-Time Visibility: Wireless Connectivity

The real revolution in recent years has been the integration of wireless technologies like Bluetooth and cellular communication into multi gas detectors. This untethers the data from the device itself and makes it available in real time.

A portable multi gas detector with Bluetooth can pair with a worker’s smartphone. The phone, running a specialized app, can then act as a gateway, relaying the detector’s readings and alarm status to a cloud-based software platform. This means a supervisor in a central control room or even off-site can see, in real time, the atmospheric conditions every member of their team is exposed to. The benefits of this are profound:

- Enhanced Situational Awareness: A supervisor can monitor a team working in a large, complex area, like during a plant shutdown. If one worker’s device alarms, the supervisor knows instantly who is in trouble, what the hazard is, and their last known location via the phone’s GPS.

- Faster Emergency Response: Instead of waiting for a worker to call for help (which they may be unable to do), an alarm on a remote dashboard can trigger an immediate response. Some systems even include a dedicated panic button on the detector or a “man-down” feature that automatically sends an alert if the user is motionless for a period of time.

- Geofencing and Automated Workflows: A supervisor can create virtual fences (geofences) around hazardous areas. When a worker with a connected detector approaches, their phone might display a reminder of required PPE or a safe work permit. This integrates the gas detection system with the broader site safety procedures.

This level of connectivity, once a feature of high-end systems, is becoming increasingly standard. It transforms the multi gas detector for confined space work from a purely personal alarm into a node in a collaborative safety network. The attendant (hole watch) standing outside the confined space is no longer reliant solely on radio communication; they can have a live dashboard showing the exact readings of the entrant’s monitor.

Managing the Fleet: Docking Stations and Software

For any organization with more than a handful of multi gas detectors, managing the fleet can be a significant logistical challenge. Are they charged? Have they been bump tested today? Are any due for calibration? Is a sensor nearing the end of its life? The modern solution to this is the intelligent docking station and its associated management software.

A docking station is much more than a charger. When a user places their portable multi gas detector in the dock at the end of their shift, the system can automatically:

- Recharge the device’s battery.

- Perform a bump test by briefly exposing the sensors to a known concentration of test gas to verify they respond correctly.

- Perform a full calibration if required, adjusting the sensor’s response to match the certified value of the calibration gas.

- Download all datalogs and event logs from the device.

- Upload any firmware updates to the device.

All this information is fed into a central software platform. A safety manager can now, from their computer, see the status of their entire fleet. They can see which devices passed or failed their bump test, generate reports on alarm frequency, track sensor life, and maintain a complete, automated record of compliance activities. This automation eliminates human error, dramatically improves efficiency, and provides invaluable insights.

A report showing frequent LEL alarms near a specific pump, for instance, is a clear indicator that the pump’s seals require maintenance. The data from the safety devices drives proactive maintenance and risk reduction. It turns the entire gas detection program from a reactive, compliance-driven necessity into a data-rich, proactive engine for continuous safety improvement.

5. Beyond the Purchase Price: Analyzing the Total Cost of Ownership (TCO)

When acquiring any significant piece of equipment, it is tempting to focus on the initial purchase price. However, for a long-lived asset like a multi gas detector, the upfront cost is often just the tip of the iceberg. A more sophisticated and ultimately more accurate approach is to evaluate the Total Cost of Ownership (TCO).

TCO considers all the direct and indirect costs associated with the device over its entire operational lifespan. A detector that appears to be a bargain on day one can easily become the more expensive option over three to five years if its maintenance needs are high or its sensors fail prematurely. A thorough TCO analysis is not just good financial practice; it is a strategic tool for ensuring the long-term sustainability and effectiveness of your gas detection program.

The initial purchase price of the instrument is the starting point. But what other costs must be factored in? Let’s break down the components of TCO for a fleet of multi gas detectors.

Cost of Consumables and Replacement Parts

This is often the largest component of ongoing costs.

- Sensors: Sensors are consumable items with a finite lifespan. A standard electrochemical sensor for CO or H₂S might last 2-3 years. An O₂ sensor might last only 1-2 years due to its constant activity. A catalytic bead LEL sensor could last 3 years, while an infrared (IR) LEL sensor might last 5 years or more. When comparing two multi gas detectors, you must look at the warranty period and the replacement cost for each sensor. A device with a lower purchase price but a short 1-year warranty on its sensors may be far more expensive than a unit with a higher initial cost but a 3 or 4-year sensor warranty.

- Calibration Gas: To perform bump tests and calibrations, you need cylinders of certified test gas. The cost of the gas itself, the regulators, and the shipping (as it’s a hazardous material) all contribute to TCO. Some docking stations are designed to be extremely efficient, using very little gas per test, which can lead to significant savings over time.

- Batteries: While most modern detectors use rechargeable lithium-ion batteries designed to last for several years, their capacity will eventually degrade. You may need to factor in a battery replacement at some point in the device’s life.

- Filters and Pump Tubing: These are minor but necessary consumables that need to be replaced periodically to ensure the device functions correctly.

Cost of Maintenance and Labor

Your team’s time is a valuable resource. A gas detection program that is complex and time-consuming to manage carries a high labor cost.

- Calibration and Bump Testing: How long does it take to perform these essential tasks? An automated docking station can bump test and download data from four devices simultaneously in a couple of minutes. Performing these tasks manually on four individual devices could take much longer, tying up a technician’s time. The efficiency gains from automation are a major factor in reducing labor-related TCO.

- Repairs and Warranty: What is the manufacturer’s typical turnaround time for repairs? A device that is out for service is a device that is not protecting a worker. Some manufacturers offer “loaner” programs to mitigate this, while others have modular designs that allow for user-replaceable sensors and parts, minimizing downtime. The length and comprehensiveness of the warranty are paramount. A 4-year, “bumper-to-bumper” warranty that covers all parts, including sensors, provides cost predictability and peace of mind.

- Training: While not a direct cost of the device, the ease of use of the detector and its associated software impacts the amount of training required for both end-users and administrators. An intuitive interface reduces training time and the likelihood of user error.

Hypothetical 5-Year TCO Comparison

To illustrate this, let’s imagine a simplified comparison for a single portable multi gas detector over a 5-year period.

| Cost Component | Detector A (Lower Initial Cost) | Detector B (Higher Initial Cost) |

| Initial Purchase Price | $800 | $1,200 |

| Sensor Warranty | 2 Years | 4 Years |

| O₂ Sensor Replacement (Year 2) | $150 | $0 (Under Warranty) |

| CO/H₂S Sensor Replacements (Year 2) | $300 | $0 (Under Warranty) |

| LEL Sensor Replacement (Year 3) | $200 | $0 (Under Warranty) |

| Full Sensor Replacement (Year 4) | $650 | $0 (Under Warranty) |

| Calibration Gas (Estimated) | $400 (Less efficient manual calibration) | $250 (More efficient dock) |

| Estimated Labor (5 Years) | $1,000 (Manual management) | $500 (Automated docking) |

| Total 5-Year Cost | $3,500 | $1,950 |

This simplified table demonstrates a crucial point: Detector B, despite being 50% more expensive at the outset, is projected to be over 40% cheaper over its operational life. This is due to its superior warranty, which eliminates sensor replacement costs in the first four years, and its compatibility with an efficient docking station that saves on both calibration gas and labor.

When you are making a purchasing decision, especially for a large fleet of multi gas detectors, it is imperative to perform this type of analysis. Ask suppliers for the cost of replacement sensors, the expected lifespan of those sensors, and data on calibration gas consumption. A commitment to evaluating the Total Cost of Ownership will not only save your organization a significant amount of money but will also likely lead you to a more reliable, robust, and easier-to-manage gas detection solution. It shifts the perspective from a short-term transaction to a long-term partnership in safety.

FAQ

Related Products

We have navigated the crucial distinction between the portable multi gas detector, the constant companion for the mobile worker and the essential tool for entering a multi gas detector for confined space, and the steadfast fixed multi gas detector, the automated sentinel guarding a specific area or process. The choice is not one of abstract preference but of contextual appropriateness, often leading to a hybrid solution that layers these defenses.

A thoughtful, well-researched, and holistic approach to your gas detection program is one of the most meaningful investments you can make in the health and safety of your people.

More Resources

-

How Do You Test for Helium?

Helium is a unique element. It is the second lightest element in the universe, chemically inert, non-flammable, and possesses the smallest atomic size…

-

How Do I Get My Carbon Monoxide Detector to Stop Chirping? (2026 Guide)

The piercing sound of a carbon monoxide (CO) detector chirping is one of the most stressful noises a homeowner can experience. It often…

-

Choosing a pH Meter for Water:The Professional Guide to(2026)

A pH meter for water is the pulse of chemical equilibrium in water treatment and industrial processing, far more than just a digital…

-

9 Best Personal Gas Monitoring Devices 2026

In the industrial world, safety is not a luxury; it is a prerequisite for operation. As we move into 2026, the technology driving…

-

What Is Dissolved Oxygen in Water? The Ultimate Guide to Monitoring(2026)

When we talk about water quality, we often focus on what we can see, like clarity, or what we can taste, like salt….

-

Mastering Safety: How to Check Gas Level in Confined Space?

The Critical Importance of Atmospheric Testing Working in industrial environments often requires entering areas that are not designed for continuous occupancy. These locations,…

.png)