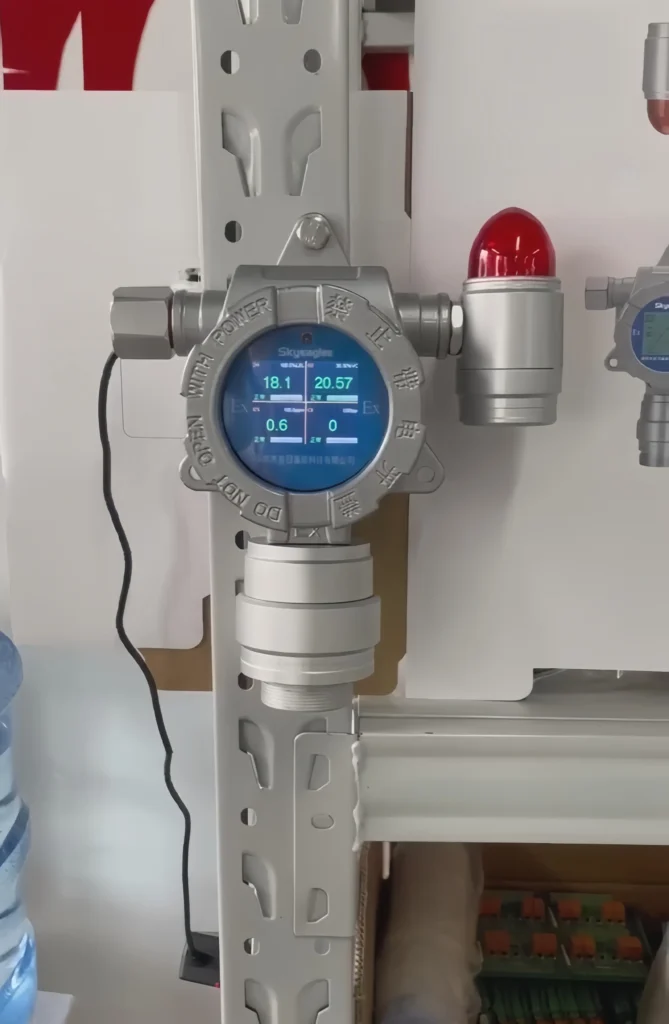

An online gas detector serves as a continuous, real-time monitoring system designed for the immediate identification and quantification of specific gases within industrial processes and ambient environments. The selection and implementation of online gas detectors represent a multifaceted decision, balancing technological capabilities with application-specific demands and regulatory obligations.

Based on Sino-Inst’s many years of experience in gas detection, we analyze the key factors in the selection process of an Online Gas Detector. This includes various gas sensing technologies (including electrochemical, catalytic, infrared, and photoionization methods), their advantages, limitations, and ideal operating environments. We also consider the significant impact of environmental variables such as temperature, humidity, and pressure, as well as the complexities of hazardous area classifications.

Our research aims to assist you in integrating these detectors into the broader plant control architecture, calibration protocols, and calculating total cost of ownership. We hope this helps you make the right online gas detector selection!

The Foundational Nature of Continuous Gas Monitoring

Before we can intelligently differentiate between a catalytic bead sensor and a tunable diode laser, or debate the merits of an in-situ versus an extractive system, we must first establish a shared understanding. What is it we are truly discussing when we speak of an “online gas detector”? The term itself suggests a connection, a live feed, a departure from the intermittent spot-checks of the past. It signifies a move toward a state of constant vigilance. This is not merely a piece of hardware; it is a philosophical commitment to awareness, a recognition that hazardous conditions can develop in seconds and that our response must be equally swift.

From Canaries to Catalytic Beads: A Brief History

The human need to detect unseen atmospheric threats is not new. The story often begins in the coal mines, with the proverbial canary. The bird’s heightened sensitivity to methane (“firedamp”) and carbon monoxide made it an effective, if tragic, biological sensor. Its distress or demise was a clear, urgent signal for miners to evacuate. Later, the flame safety lamp, while intended for illumination, offered a more technical, though still subjective, method. An experienced miner could estimate the methane concentration by observing changes in the flame’s height and color (iceweb.eit.edu.au). These early methods, however, were imprecise and relied heavily on human interpretation, a variable we perpetually seek to minimize in matters of safety.

The mid-20th century brought the advent of electronic devices, marking a significant leap forward. The development of the catalytic bead sensor, or pellistor, in the 1960s provided a reliable, repeatable way to measure combustible gases. This technology, along with the emergence of electrochemical sensors for toxic gases, formed the bedrock of modern gas detection for decades. We moved from observing a living creature or a flickering flame to reading a quantitative value on a dial or digital display—a profound shift from qualitative warning to quantitative measurement (Debuy, 2025).

The Modern Imperative: Safety, Compliance, and Process Optimization

Today, the reasons for employing an online gas detector are threefold, forming a triad of industrial responsibility.

The first and most immediate is safety. The presence of flammable gases can lead to catastrophic explosions. Toxic gases, even at parts-per-million (ppm) concentrations, can cause immediate harm or long-term health effects. An oxygen deficiency can lead to asphyxiation, while an oxygen-enriched atmosphere can dramatically increase fire risk. An online gas detector is a facility’s first line of defense, a sentry that never sleeps, providing the critical early warning needed to trigger alarms, activate ventilation, or initiate a process shutdown.

The second imperative is regulatory compliance. Governmental bodies worldwide, such as the Occupational Safety and Health Administration (OSHA) in the United States or through European ATEX directives, mandate the monitoring of specific airborne hazards to protect workers and the public. Environmental agencies, like the U.S. Environmental Protection Agency (EPA), impose strict limits on the emission of pollutants such as sulfur dioxide (SO₂), nitrogen oxides (NOx), and volatile organic compounds (VOCs). An online gas analyzer often forms the core of a Continuous Emission Monitoring System (CEMS), providing the legally required data to demonstrate compliance. Failure to do so can result in severe financial penalties and operational shutdowns.

The third, and often overlooked, imperative is process optimization. In many chemical, pharmaceutical, and manufacturing processes, gases are either reactants or products. Monitoring the concentration of CO₂ in a fermentation process, H₂ in a hydrogenation reaction, or ensuring the absence of O₂ in an inert blanketing application is not just about safety; it is about efficiency, quality, and yield. An online gas analysis system provides real-time feedback that allows operators to fine-tune process parameters, maximizing output and minimizing waste.

Defining “Online”: Continuous, Real-Time Monitoring Explained

What elevates a detector to “online” status? The term distinguishes these systems from portable, handheld detectors used for personal protection or spot checks, and from laboratory-based methods like gas chromatography, which analyze discrete samples with a significant time delay. An online gas detector is a fixed installation, permanently integrated into the process or area it monitors. It operates continuously, 24/7, and provides its output in real-time (or near real-time).

This “real-time” aspect is fundamental. It means the data generated reflects the atmospheric conditions at that very moment, enabling immediate automated or manual intervention. The output is typically an electronic signal—most commonly a 4-20mA analog signal or a digital protocol like Modbus—that is fed directly into a plant’s Distributed Control System (DCS), Programmable Logic Controller (PLC), or a dedicated gas detection controller. It is this seamless integration, this transformation of a chemical concentration into an actionable electronic signal, that defines the power and purpose of an online gas detector.

Factor 1: Aligning Sensing Technology with Chemical Reality

The heart of any online gas detector is its sensor. This is the component that performs the magical task of translating the presence of a specific chemical in the air into a measurable signal. There is no single “best” sensor technology; the choice is entirely contingent upon the target gas, the required measurement range, the presence of other gases, and the operational budget. Selecting the wrong technology is akin to choosing a thermometer to measure distance—it is simply the wrong tool for the job, and the results will be meaningless at best and dangerously misleading at worst. Let’s examine the primary technologies you will encounter.

To help clarify these choices, consider the following comparison:

| Technology | Principle | Common Targets | Strengths | Weaknesses |

| Electrochemical (EC) | Chemical reaction creates current | Toxic gases (CO, H₂S, Cl₂), O₂ | High sensitivity (ppm), low cost, low power | Consumable, cross-interference, limited life |

| Catalytic Bead | Catalytic oxidation releases heat | Combustible gases (%LEL) | Robust, proven, low cost, broad range | Requires O₂, susceptible to poisons, high power |

| Infrared (IR) | Absorption of IR light | Hydrocarbons (%LEL, %Vol), CO₂ | Immune to poisons, no O₂ needed, long life | Higher cost, cannot detect H₂, humidity effects |

| Photoionization (PID) | UV light ionizes molecules | Volatile Organic Compounds (VOCs) | Very high sensitivity (ppb), fast response | Non-specific, humidity effects, lamp life |

| Tunable Diode Laser | Absorption of specific laser light | NH₃, HCl, O₂, H₂O, etc. | Extremely specific, fast, stable, low maintenance | High initial cost, typically single-gas |

Factor 2: Appraising the Demands of the Operational Environment

A gas detector does not operate in a vacuum. It is a sensitive instrument that must survive and function reliably within the often-hostile environment of an industrial facility. Ignoring the operational context is a recipe for failure. The ambient conditions can directly affect sensor accuracy, lifespan, and even the fundamental safety of the installation itself. As noted by Cepa et al. (2023), virtually all sensor types are subject to measurement deviations due to environmental conditions.

Temperature, Humidity, and Pressure: The Environmental Triad

These three parameters are the most common sources of measurement error and sensor damage if not properly accounted for.

Temperature: Extreme heat can accelerate the degradation of sensor components, particularly the electrolyte in EC sensors, drastically shortening their life. Extreme cold can slow down the chemical reactions in both EC and catalytic sensors, leading to sluggish responses and inaccurate readings. Most standard online gas detectors have a defined operating temperature range (e.g., -20°C to +70°C). For applications outside this range, such as in cryogenic processes or high-temperature stacks, specialized systems with heating, cooling, or extractive sampling with sample conditioning are required.

Humidity: High humidity can be problematic for several sensor types. For PIDs, water vapor can partially quench the UV lamp’s energy, leading to lower readings, a phenomenon known as “humidity bias.” For IR sensors, water vapor absorbs IR radiation at certain wavelengths, which can interfere with the measurement of some hydrocarbons if not properly compensated for. Condensation on optical surfaces can block the light path entirely. Conversely, very low humidity can cause the electrolyte in EC sensors to dry out prematurely.

Pressure: Variations in atmospheric pressure can directly affect the readings of most sensor types. A sensor calibrated at sea level will read differently at a high-altitude facility because the partial pressure of the target gas changes even if the volumetric concentration remains the same. For sensors installed directly in a pressurized or vacuum process line, the effect is even more pronounced. Most detectors are designed for atmospheric pressure, and readings must be corrected or specialized pressure-compensated sensors must be used for other applications.

Hazardous Area Classifications: Understanding ATEX, IECEx, and North American Standards

In many industrial settings, the very reason you need a gas detector is because the atmosphere could be, or is, potentially explosive. It is absolutely forbidden to install a piece of electrical equipment in such an area if it could itself become an ignition source (e.g., from a spark or a hot surface). Therefore, any online gas detector intended for these locations must be certified as safe for that specific environment.

This is where hazardous area classifications come in. These are globally recognized standards that classify areas based on the likelihood of an explosive atmosphere being present.

- North American System (NEC/CEC): Uses a Class/Division system. Class I is for flammable gases or vapors. Division 1 is an area where explosive concentrations are present continuously or intermittently under normal operating conditions. Division 2 is an area where they are present only under abnormal conditions (e.g., a leak).

- IEC/ATEX System (Europe and much of the world): Uses a Zone system. Zone 0 (equivalent to Div 1) is an area where an explosive atmosphere is present continuously. Zone 1 is an area where it is likely to occur in normal operation. Zone 2 (equivalent to Div 2) is an area where it is unlikely to occur, and if it does, only for a short period.

An online gas detector must carry a certification label (e.g., from UL, CSA, ATEX, IECEx) that explicitly states it is approved for the specific Class/Division or Zone in which it will be installed. The protection method used to achieve this certification is also specified, such as “Explosion-proof/Flameproof” (housed in a robust enclosure that can contain an internal explosion) or “Intrinsically Safe” (designed to operate on such low levels of energy that it cannot create a spark). Installing a non-certified “general purpose” detector in a hazardous area is a serious safety violation.

The Challenge of Cross-Interference and Sensor Poisoning

The ideal sensor would respond only to its target gas and ignore everything else. In reality, this is rarely the case.

- Cross-Interference: This occurs when a sensor designed for one gas reacts to the presence of another. A classic example is an EC sensor for carbon monoxide, which will often show a positive response to hydrogen. A hydrogen sulfide sensor might react to high concentrations of sulfur dioxide. Reputable manufacturers provide detailed cross-interference charts for their sensors. It is your responsibility to review the chemical inventory of the monitoring area and compare it against these charts. If a significant interferent is always present, you may need to choose a different sensing technology (like IR or TDL) that is more specific.

- Sensor Poisoning: This is a more permanent problem than interference. Certain chemicals can irreversibly damage a sensor, rendering it useless. As mentioned earlier, catalytic bead sensors are notoriously vulnerable to poisons like silicones (found in some lubricants and sealants), lead, and sulfur compounds. Even a small, one-time exposure can destroy the sensor’s ability to detect combustible gases. In environments where such poisons are known to be present, an IR sensor is a far more reliable choice for hydrocarbon detection.

Understanding your complete chemical environment is not an optional step; it is a prerequisite for selecting a reliable online gas detection system.

Factor 3: The Strategic Decision Between In-Situ and Extractive Analysis

Once you have a grasp of the best sensing technology for your gas and the environmental challenges, you face a major architectural choice: how will the gas get to the sensor? There are two fundamental approaches: bringing the sensor to the gas (in-situ) or bringing the gas to the sensor (extractive). This decision impacts system complexity, response time, maintenance, and cost.

The In-Situ Approach: Monitoring Directly Within the Process Stream

In-situ, meaning “in position,” refers to systems where the sensing element is placed directly in the environment to be monitored. This could be a sensor head mounted on a wall to monitor ambient air in a room, or a probe inserted directly into a process pipe or exhaust stack.

- Advantages: The primary advantage of in-situ analysis is speed. There is no delay from pulling a sample through tubing; the sensor “sees” the gas concentration in real-time. This is invaluable for fast-developing safety situations. The systems are often simpler in design, with fewer components to fail (no pumps, valves, or sample lines). This can lead to lower installation costs and fewer maintenance headaches. Open-path IR and TDL detectors are a form of in-situ monitoring, where a beam of light is sent across a large open area (e.g., along a pipeline or across a facility’s fenceline) to a receiver, providing average concentration readings over long distances.

- Disadvantages: The sensor is exposed to the full force of the process conditions. If the gas stream is very hot, corrosive, wet, or full of particulate matter, it can quickly damage or foul the sensor, leading to frequent failures and maintenance. Servicing or calibrating the sensor can be difficult if it is located in a hard-to-reach area, like high up on a stack or inside a confined space.

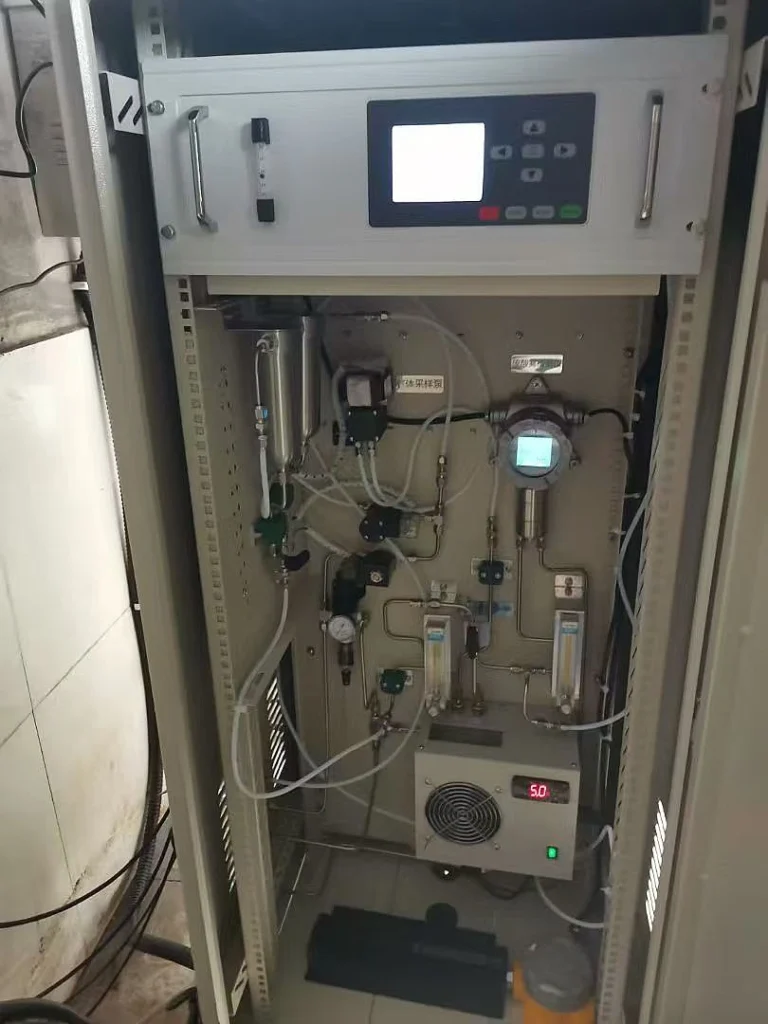

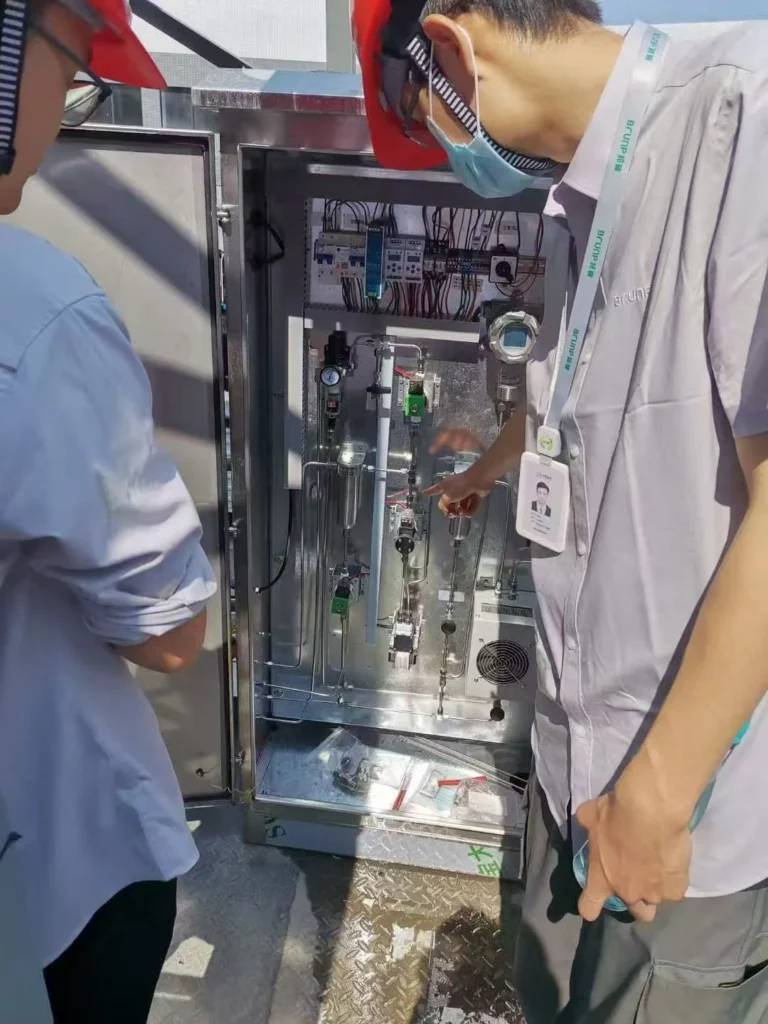

The Extractive Method: Bringing the Sample to the Analyzer

Extractive systems work by actively pulling a sample of the gas from the monitoring point and transporting it, via a pump and sample tubing, to an analyzer located in a more convenient and controlled environment. The analyzer itself is often a complex piece of equipment housed in a dedicated shelter or enclosure.

- Advantages: The biggest advantage is control. The gas sample can be “conditioned” before it reaches the analyzer. This means it can be cooled, filtered to remove dust and particulates, and dried to remove moisture. This protects the sensitive analyzer components and eliminates many of the environmental interferences discussed earlier, leading to a more stable and accurate measurement. The analyzer is located in an accessible, safe location, making calibration, maintenance, and repair vastly easier. A single, sophisticated analyzer can be used to monitor samples from multiple different points by using a stream-switching valve system.

- Disadvantages: The primary drawbacks are complexity and time delay. These systems involve pumps, filters, valves, flowmeters, and extensive tubing, all of which require maintenance and can be potential points of failure. There is an inherent time lag between a change in gas concentration at the sample point and its detection by the analyzer, which depends on the length of the sample line and the flow rate. This delay can be unacceptable for certain critical safety applications. Extractive systems, particularly those with extensive sample conditioning, have a higher initial cost and greater complexity.

In-Situ vs. Extractive Systems: A Decision Matrix

The choice is rarely clear-cut and depends on a careful weighing of priorities. This matrix can help guide your thinking:

| Response Time | Critical, near-instantaneous response needed (e.g., LEL detection for explosion prevention). | A delay of seconds to a few minutes is acceptable (e.g., emissions monitoring). |

| Process Conditions | Clean, dry gas at moderate temperature and pressure. | Hot, wet, dusty, corrosive, or high-pressure gas stream. |

| Measurement Point | Easily accessible for calibration and service. | Inaccessible or hazardous location (e.g., top of a stack, inside a reactor). |

| Maintenance | Desire for system simplicity with fewer moving parts. | Willingness to maintain a more complex system for higher accuracy/reliability. |

| Gases / Analytes | Single gas, ambient monitoring. | Multiple sample points, complex gas matrix requiring advanced, protected single gas monitoring systems. |

| Budget | Lower initial capital expenditure is a priority. | Higher accuracy and long-term stability justify a larger initial investment. |

Sample Conditioning: The Unsung Hero of Extractive Systems

For extractive systems, the sample conditioning unit is arguably as important as the analyzer itself. A poorly designed conditioning system will deliver a non-representative sample or fail frequently, rendering the entire system useless. Key components include:

- Particulate Filters: A series of filters, starting with a coarse filter at the sample probe and progressing to finer filters, removes dust that could clog the system or foul the analyzer.

- Moisture Removal: This is often the most challenging part. Options range from simple knockout pots for bulk liquids to more sophisticated permeation dryers (like Nafion™ tubes) or thermoelectric coolers that chill the sample to a consistent dew point, condensing out the water.

- Pumps: A reliable, corrosion-resistant pump (typically a diaphragm pump) is needed to pull the sample from the process to the analyzer.

- Flow Control: A flowmeter and valve are needed to ensure a constant, known flow rate to the analyzer, which is essential for a stable reading.

Designing a sample conditioning system requires a deep understanding of the process gas chemistry and physical properties. It is often where the expertise of an experienced instrument provider becomes most valuable.

Factor 4: Integrating with the Plant’s Nervous System

An online gas detector that is not connected to anything is just an expensive paperweight. Its purpose is to communicate information to a system—and to people—that can act on it. The effectiveness of a gas detection system is therefore critically dependent on how well it is integrated into the facility’s broader process control and safety infrastructure. This is the “online” part of the online gas detector.

Analog vs. Digital Outputs: From 4-20mA to Modbus and HART

The detector must translate its measurement into a language that the plant’s control system can understand. For decades, the universal language was the 4-20mA analog signal.

- 4-20mA Analog Signal: In this system, the detector outputs a direct current that varies in proportion to the gas concentration. 4mA typically represents zero gas, and 20mA represents the full-scale range of the sensor. This is a simple, robust, and well-understood standard. A key advantage is its live-zero feature: a current of 0mA indicates a fault (e.g., a cut wire), distinguishing it from a zero-gas reading (4mA).

- Digital Protocols (Modbus, HART, Fieldbus): Modern detectors increasingly use digital communication protocols. These offer significant advantages over simple analog signals.

- HART (Highway Addressable Remote Transducer): This is a hybrid protocol that superimposes a digital signal on top of the standard 4-20mA analog signal. It allows for the transmission of much more information than just the gas concentration. For example, a technician can remotely access the detector’s diagnostic information, check its status, view its event logs, and even initiate a calibration without having to physically go to the device.

- Modbus, Foundation Fieldbus, Profibus: These are fully digital, multi-drop protocols that allow numerous devices to communicate on a single pair of wires, reducing wiring costs. They provide a rich set of data from each device, including primary measurements, secondary parameters (like sensor temperature), diagnostic flags, and configuration settings.

The choice of output depends on the existing plant infrastructure. If the facility uses a legacy PLC that only accepts 4-20mA inputs, that may be the only option. However, for new installations or major upgrades, a digital protocol offers far greater functionality and insight into the health and performance of the gas detection system.

Designing Alarm Logic and Emergency Shutdown (ESD) Sequences

Getting the signal to the control system is only the first step. The control system must then be programmed to do something with that information. This is where alarm logic comes in. A typical setup for a gas detector involves multiple alarm setpoints:

- Low Alarm: A warning level, often set at 10-25% of the hazardous concentration. This might trigger a visual beacon (a flashing light) and an audible horn to alert personnel in the area to a developing situation.

- High Alarm: A danger level, often set at 40-60% of the hazardous concentration. This would trigger more urgent alarms and might initiate automated actions.

- High-High Alarm: A critical level that demands immediate, drastic action.

The actions triggered by these alarms can range from simple notifications to complex, automated safety sequences. For example, a high alarm for a toxic gas in a room might automatically start an emergency ventilation fan. A high-high LEL alarm for a flammable gas in a compressor shed might trigger an Emergency Shutdown (ESD) system, which would de-energize electrical equipment in the area, shut down the process, and perhaps even activate a fire suppression system like a water deluge.

Designing this logic requires a formal risk assessment process (like a HAZOP study) to determine the appropriate response for each scenario. The goal is to create a tiered response that mitigates the hazard effectively while avoiding unnecessary and costly process shutdowns from minor or spurious alarms.

The Rise of Smart Sensors and the Industrial Internet of Things (IIoT)

The move toward digital protocols is part of a larger trend toward “smart” sensors and the IIoT. Modern gas detectors are no longer just simple transducers; they are microprocessor-based devices with significant onboard intelligence (Mao, 2024). This intelligence allows them to perform self-diagnostics, store calibration and event data, and communicate detailed status information.

When integrated into an IIoT platform, the data from hundreds or thousands of advanced online gas detector solutions across a facility can be aggregated and analyzed. This opens up new possibilities:

- Centralized Monitoring: Safety officers can view the status of every gas detector in the entire plant from a single dashboard on a PC or tablet.

- Predictive Maintenance: By analyzing trends in sensor performance (e.g., a slow drift in the zero reading or a decrease in sensitivity during calibration), the system can predict when a sensor is nearing the end of its life and schedule a replacement before it fails unexpectedly.

- Data-Driven Safety Insights: By correlating gas detection data with process data and operational events, companies can identify previously unknown risks or “hot spots” where small leaks occur frequently. This allows them to move from a reactive safety posture to a proactive, predictive one.

This integration of sensing, communication, and data analytics represents the future of industrial safety and is transforming the role of the humble gas detector from a simple alarm device into a rich source of operational intelligence.

Factor 5: The Economics of Safety: Calibration, Maintenance, and Lifetime Cost

A common mistake in procuring an online gas detector is to focus solely on the initial purchase price. The reality is that the upfront cost is often just a fraction of the total cost of ownership (TCO) over the instrument’s lifespan. Maintenance, calibration, and consumables can easily dwarf the initial hardware cost. A seemingly “cheap” detector can become a very expensive problem if it requires constant attention and frequent replacement of parts.

The Non-Negotiable Reality of Calibration

Every gas sensor, without exception, will drift over time. Its response to a given gas concentration will change due to aging, environmental effects, or minor exposures to contaminants. Calibration is the process of correcting for this drift. It involves exposing the sensor to a known concentration of gas (a “span gas”) and adjusting the instrument’s output to match. A “zero” check, using clean air or nitrogen, is also performed to ensure the sensor reads zero when no target gas is present.

- Why is it necessary? An uncalibrated sensor is an untrustworthy sensor. It might fail to alarm in a dangerous situation (a false negative) or trigger frequent false alarms (a false positive). Both outcomes undermine the very purpose of the system and erode operator confidence. Regulatory bodies like OSHA require that gas detection instruments be calibrated according to the manufacturer’s recommendations.

- How often? The required frequency depends on the sensor technology, the application, and company policy. Electrochemical sensors might require calibration every 3 to 6 months. Catalytic and IR sensors are generally more stable and might only need calibration every 6 to 12 months. Some advanced technologies like TDL may be stable for years after initial commissioning. However, a “bump test” (a brief exposure to gas to confirm the sensor responds and alarms trigger) should be performed much more frequently, perhaps even before each use in some portable applications.

- The Cost: The cost of calibration includes the price of the certified calibration gas cylinders, the regulators, the labor required to perform the procedure, and any associated record-keeping and documentation. For a plant with hundreds of detectors, this can be a very significant ongoing operational expense. Systems with auto-calibration features can reduce the labor cost, but the cost of gas remains.

Predictive Maintenance: Moving Beyond a Fixed Schedule

Traditionally, maintenance has been performed on a fixed schedule (e.g., “replace EC sensor every two years”). The advent of smart sensors allows for a more intelligent, condition-based approach. By monitoring the internal diagnostics of the detector, maintenance can be scheduled when it is actually needed, not just when the calendar says so.

For example, the control system might monitor the remaining sensor life percentage reported by a smart EC sensor. Or it might track the intensity of the light source in an IR detector. When these parameters fall below a certain threshold, a work order for replacement is automatically generated. This approach, known as predictive maintenance, offers several benefits:

- Avoids Unexpected Failures: It prevents sensors from failing in service, ensuring the system is always available.

- Maximizes Component Life: It avoids the wasteful practice of replacing components that are still perfectly functional, just because they have reached a certain age.

- Optimizes Labor: It allows maintenance teams to plan their work more efficiently, rather than constantly reacting to failures.

Calculating TCO: Looking Beyond the Initial Purchase Price

To make an informed financial decision, you must calculate the Total Cost of Ownership. Think of it like buying a car: the sticker price is just the beginning. You also have to pay for fuel, insurance, oil changes, and tire replacements. For an online gas detector, the TCO calculation should include:

- Initial Purchase Cost: The price of the detector, mounting hardware, and any associated controller or junction boxes.

- Installation Cost: Labor for mounting, wiring, and commissioning. This can be substantial, especially for complex extractive systems.

- Consumables Cost: The projected cost of replacement sensors, calibration gas, filters, and pump diaphragms over a set period (e.g., 5 or 10 years). Remember that an inexpensive detector with a sensor that lasts only one year may be more expensive in the long run than a pricier detector with a sensor that lasts five years.

- Maintenance Labor Cost: The estimated time (and cost) for personnel to perform routine calibrations, bump tests, and component replacements.

- Training Cost: The cost to train personnel on how to properly use and maintain the system.

When you compare different systems based on their 5-year or 10-year TCO, you often get a very different picture than if you just compare their initial price tags. The more reliable, stable, and low-maintenance system, even if it has a higher upfront cost, frequently proves to be the more economical choice over the long term.

Factor 6: Navigating the Labyrinth of Regulation and Certification

Industrial operations are governed by a complex web of regulations designed to protect workers, the public, and the environment. An online gas detector is often a key piece of equipment used to demonstrate compliance with these regulations. Therefore, the system you choose must meet the specific legal and performance standards applicable to your industry and location. Failure to do so can lead to legal liability, fines, and forced shutdowns.

Navigating EPA, OSHA, and International Equivalents

In the United States, two major federal agencies dictate many of the requirements for gas detection:

- OSHA (Occupational Safety and Health Administration): OSHA’s primary mission is to ensure safe and healthful working conditions. They set Permissible Exposure Limits (PELs) for hundreds of toxic chemicals. For example, the PEL for H₂S is 20 ppm. Gas detection systems used for personnel safety must be able to accurately measure and alarm at levels relevant to these PELs. OSHA also has specific standards for confined space entry (29 CFR 1910.146), which mandates atmospheric testing for oxygen content, flammable gases, and potential toxic air contaminants before entry.

- EPA (Environmental Protection Agency): The EPA regulates the release of pollutants into the atmosphere under the Clean Air Act. They set strict limits on emissions from industrial facilities. An online gas detector may be part of a Continuous Emission Monitoring System (CEMS) required under regulations like 40 CFR Part 60 or Part 75. These systems must meet rigorous performance specifications for accuracy, calibration drift, and uptime.

Other countries and regions have their own equivalent bodies and regulations, such as the Health and Safety Executive (HSE) in the UK, which sets Workplace Exposure Limits (WELs), and various environmental agencies that enforce the European Industrial Emissions Directive. It is essential to identify all applicable national, state/provincial, and local regulations before specifying a gas detection system.

Understanding Performance Standards (e.g., SIL Ratings)

Beyond government regulations, many industries adhere to performance-based safety standards. One of the most important is IEC 61508/61511, which deals with functional safety and Safety Integrity Levels (SIL).

A SIL rating is a measure of the reliability of a Safety Instrumented System (SIS), which is an automated system designed to prevent or mitigate a hazardous event (e.g., an ESD system). The SIL level (from 1 to 4) represents the degree of risk reduction the system provides. A SIL 2 system, for example, must have a probability of failure on demand (PFD) between 1 in 1,000 and 1 in 10,000.

To build a SIL-rated safety system, every component in that system—from the sensor to the logic solver (PLC) to the final element (e.g., a valve)—must itself be certified for use in that SIL level. An online gas detector intended for use in a SIL 2 loop must have a SIL 2 “capability” certification. This means the manufacturer has performed a rigorous failure mode and effects analysis (FMEA), can provide the necessary reliability data (like PFD and Safe Failure Fraction), and has a certified quality management process for its design and manufacturing. Using a non-certified detector in a SIL-rated safety function invalidates the entire safety claim.

Continuous Emission Monitoring Systems (CEMS) as a Specialized Application

CEMS are a highly specialized and regulated class of online gas analysis systems. Their sole purpose is to provide the data to prove to a regulatory agency that a facility’s emissions are within its permitted limits. These systems typically monitor flue gases from boilers, incinerators, or industrial processes for pollutants like SO₂, NOx, CO, O₂, and sometimes mercury or HCl.

CEMS are subject to extremely stringent performance and quality assurance requirements. They must undergo a formal certification process that includes a Relative Accuracy Test Audit (RATA), where the CEMS readings are compared against an independent reference method. They also require daily calibration checks and quarterly quality audits. The analyzers used in CEMS applications (often extractive systems using IR, UV, or chemiluminescence technologies) must be designed for exceptional stability, accuracy, and reliability to meet these demands. Selecting a CEMS is a major undertaking that requires deep expertise in both instrumentation and environmental regulations.

Factor 7: Choosing a Partner for the Journey, Not Just a Product for the Shelf

In a field as complex and critical as gas detection, the relationship with your supplier is as important as the hardware they provide. A box full of sensors and wires is of little use without the expertise to apply it correctly. The best outcomes are achieved when you view your supplier not as a mere vendor, but as a long-term partner in your safety and operational goals.

The Value of Application Expertise and Technical Support

Every industry and every process has its own unique challenges. The gas detection needs of a pharmaceutical cleanroom are vastly different from those of an offshore oil rig or a municipal wastewater plant. An experienced supplier has seen these challenges before. They can provide invaluable guidance based on real-world experience.

Think about these questions when evaluating a potential supplier:

- Do they ask probing questions about your process, your chemical inventory, and your operational goals? Or do they just try to sell you the product on their shelf?

- Can they explain the pros and cons of different sensing technologies as they relate to your specific application?

- Can they share case studies or references from similar applications in your industry?

- What level of technical support do they offer after the sale? Is there a knowledgeable person you can call when you run into trouble during installation or commissioning?

A good partner helps you avoid common pitfalls, like placing a sensor in a “dead air” spot where a leak would never reach it, or selecting a sensor that will be poisoned by a cleaning solvent used in the plant. This application expertise is often the difference between a system that works on paper and a system that works in reality. As MSA Safety highlights in their handbook, understanding the key principles is fundamental to proper application (us.msasafety.com).

Evaluating Supplier Documentation and Training Resources

A well-documented system is a maintainable system. Before you buy, ask to see the product manuals, installation guides, and calibration procedures. Are they clear, comprehensive, and easy to understand for your technicians? Poor documentation can lead to incorrect installation, improper maintenance, and ultimately, system failure.

Training is another critical component. Your team—from the engineers who design the system to the technicians who maintain it and the operators who respond to its alarms—must be properly trained. Does the supplier offer factory or on-site training programs? Do they have online resources, videos, or webinars that can be used for ongoing education? Investing in training is investing in the long-term success and reliability of your gas detection program.

Future-Proofing Your Investment: Scalability and Upgradability

Your facility’s needs will change over time. Processes are modified, new chemicals are introduced, and regulations become stricter. The online gas detection system you install today should be able to adapt to the needs of tomorrow.

- Scalability: How easy is it to add more detection points to the system? If you use a digital communication protocol, adding another sensor might be as simple as connecting it to the existing network cable. With an older analog system, it might require pulling new wires all the way back to the control room.

- Upgradability: Can the system’s firmware be updated to add new features or improve performance? Can you swap out a sensor for a different type if your monitoring needs change? Choosing a system based on an open, modular platform provides much more flexibility than a closed, proprietary system.

By selecting a forward-thinking partner who offers scalable and upgradable solutions, you are not just solving today’s problem; you are making a strategic investment that will continue to provide value and protection for years to come.

FAQ

Related Products

The selection and implementation of an online gas detector is a task of profound technical and ethical significance. We have journeyed through the intricacies of sensing technologies, the challenges of hostile environments, and the complexities of system integration. We have weighed the economic realities of ownership against the non-negotiable demands of safety and regulation.

This is not merely an exercise in engineering or procurement. At its core, it is an act of care. It is a tangible expression of an organization’s commitment to the well-being of its people, the preservation of its assets, and its stewardship of the surrounding environment.

We at Sino-Inst specialize in supplying gas detection instruments. Online Gas Detectors can be customized according to the type of gas you need to detect, environmental parameters, etc.

More Resources

-

How Do You Test for Helium?

Helium is a unique element. It is the second lightest element in the universe, chemically inert, non-flammable, and possesses the smallest atomic size…

-

How Do I Get My Carbon Monoxide Detector to Stop Chirping? (2026 Guide)

The piercing sound of a carbon monoxide (CO) detector chirping is one of the most stressful noises a homeowner can experience. It often…

-

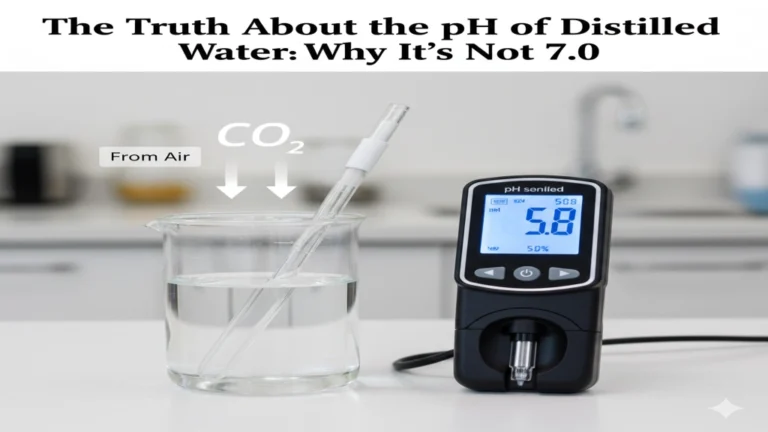

Choosing a pH Meter for Water:The Professional Guide to(2026)

A pH meter for water is the pulse of chemical equilibrium in water treatment and industrial processing, far more than just a digital…

-

9 Best Personal Gas Monitoring Devices 2026

In the industrial world, safety is not a luxury; it is a prerequisite for operation. As we move into 2026, the technology driving…

-

What Is Dissolved Oxygen in Water? The Ultimate Guide to Monitoring(2026)

When we talk about water quality, we often focus on what we can see, like clarity, or what we can taste, like salt….

-

Mastering Safety: How to Check Gas Level in Confined Space?

The Critical Importance of Atmospheric Testing Working in industrial environments often requires entering areas that are not designed for continuous occupancy. These locations,…

.png)