In industrial safety, the margin for error is non-existent. Whether managing a petrochemical refinery, an agricultural greenhouse, or a manufacturing plant, the ability to identify hazardous emissions instantly is critical. From our experience in process instrumentation, we know that relying on a single detection method is often insufficient. To ensure comprehensive safety, one must understand the specific technology and form factor required for the application. Not every detector detects gas leaks with the same efficiency in every environment.

We have categorized the five most essential types of detectors used in modern industry. This classification covers both the deployment method (Fixed vs. Portable) and the sensing technologies that drive them. Selecting the correct combination is the only way to guarantee personnel safety and asset protection.

1. Fixed Gas Detectors

When continuous, 24/7 surveillance is required, fixed systems are the industry standard. These units are permanently mounted in high-risk areas—such as near storage tanks, compressor stations, or confined spaces—to create a safety perimeter.

A high-quality fixed detector detects gas leaks by monitoring the environment for specific toxic, harmful, or flammable gases. We recommend these for “Zone 0” or “Zone 1” hazardous areas where human presence is intermittent but the risk is constant. Modern systems, such as those offered by Sino-Inst, provide real-time monitoring and can detect the composition and concentration of gases of concern with high precision.

The primary advantage here is integration. These detectors typically offer customizable detection options (one to seven gases) and provide signal outputs like 4-20mA, RS485, and digital signals. This enables easy integration into industrial control systems such as PLCs, DCSs, and DDCs, allowing for automated shutdowns if a leak is detected.

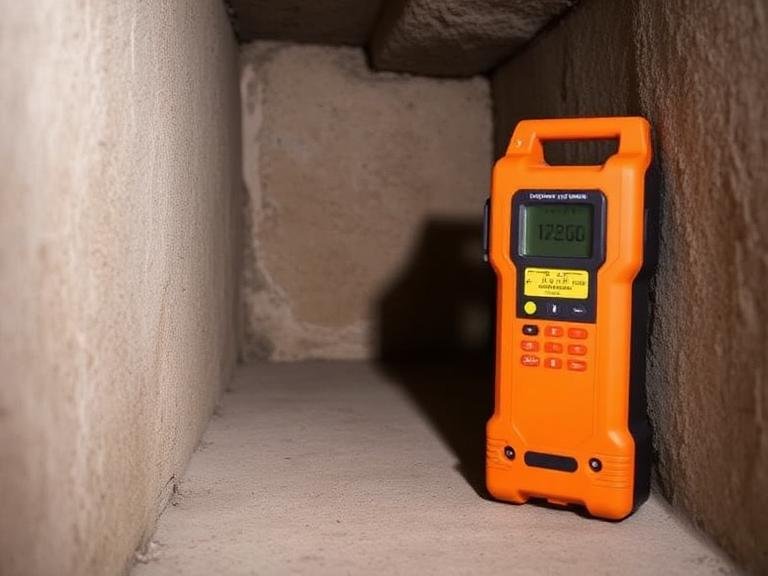

2. Portable Gas Detectors

While fixed systems protect the facility, portable detectors protect the person. We view these as mandatory Personal Protective Equipment (PPE) for any technician entering a confined space or a potential leak zone. These independent units are lightweight, compact, and designed for mobile use.

Sino-Inst’s portable gas detectors are exemplary in this category. They are engineered to verify the atmosphere before entry, ensuring that oxygen levels are sufficient and that no toxic gases are present. They are widely used to monitor exhaust emissions and air pollution in urban environments and agricultural greenhouses. The key feature to look for is the ability to accurately capture small changes in gas concentrations in real time, promptly detecting potential safety hazards before they reach a critical threshold.

3. Electrochemical Gas Sensors

When the target is a toxic gas like Carbon Monoxide (CO), Hydrogen Sulfide (H2S), or Chlorine (Cl2), electrochemical sensors are the superior choice. These sensors operate by reacting with the gas of interest to produce an electrical signal proportional to the gas concentration.

From our technical analysis, electrochemical sensors offer the best sensitivity for toxic gases at low parts-per-million (ppm) levels. However, they are less effective in extreme temperatures. If you need a detector detects gas leaks involving toxic substances in a standard temperature environment, this technology is highly reliable and cost-effective.

4. Infrared (IR) Optical Detectors

For hydrocarbon gas detection (like Methane, Propane, or Butane) in oxygen-deficient environments, Infrared technology is essential. Unlike catalytic bead sensors that require oxygen to function, IR detectors use a light beam to identify gas presence. The gas absorbs specific wavelengths of light, and the detector measures the reduction in light intensity.

We recommend IR detectors for rigorous industrial environments because they are immune to poisoning from silicones or sulfur, which typically destroy other sensor types. They are robust, require less calibration, and provide a fail-safe operation mode.

5. Ultrasonic Gas Leak Detectors

Ultrasonic detection is unique because it does not measure gas concentration; it listens for the leak itself. When pressurized gas escapes a pipe, it generates a distinct ultrasonic noise. An acoustic detector detects gas leaks by identifying this sound frequency.

This technology is invaluable in outdoor, windy environments where a traditional gas plume might be blown away from a point sensor. By detecting the sound of the leak, these units provide an instant alarm regardless of wind direction or gas dilution. We typically deploy these in conjunction with fixed point detectors for a layered defense strategy.

Integration: Sino-Inst Industrial Solutions

At Sino-Inst, we understand that data integration is just as important as detection. Our detection solutions are designed to bridge the gap between safety hardware and control logic.

- Data Connectivity: Our fixed detectors seamlessly output to RS485 and 4-20mA standards, ensuring your PLC knows exactly what is happening on the floor.

- Customization: We offer customizable detection options for up to seven gases simultaneously, tailoring the device to your specific hazard profile.

- Risk Reduction: Installing appropriate Fixed Gas Detectors significantly reduces the threat of explosive gas leaks or overexposure to toxic gases.

Summary Comparison Table

| Detector Type | Best For | Primary Technology | Key Advantage |

|---|---|---|---|

| Fixed Gas Detectors | 24/7 Area Monitoring | Various (EC, IR, Catalytic) | Automation & PLC Integration |

| Portable Gas Detectors | Personnel Safety / Confined Space | Various | Mobility & Real-time Personal Alarms |

| Electrochemical | Toxic Gases (CO, H2S) | Chemical Reaction | High Sensitivity at Low PPM |

| Infrared (IR) | Combustible Hydrocarbons | Optical Absorption | Works in Inert (No Oxygen) Atmospheres |

| Ultrasonic | Pressurized Leaks / Windy Areas | Acoustic Sensing | Instant Detection at Speed of Sound |

Frequently Asked Questions

Which detector detects gas leaks best for home use?

For residential use, a catalytic bead or semiconductor sensor is common for combustible gases (natural gas), while electrochemical sensors are standard for Carbon Monoxide (CO) alarms.

Can a portable detector replace a fixed system?

No. Portable detectors are for intermittent use by personnel. They do not provide the continuous, wide-area coverage and automated control system integration that a fixed detector detects gas leaks with.

How often should gas detectors be calibrated?

We recommend a bump test before every use for portable units and a full calibration every 6 months (or according to manufacturer specs) for fixed systems to ensure sensor accuracy.

Do Sino-Inst detectors work with existing DCS systems?

Yes. Our fixed gas detectors provide standard signal outputs including 4-20mA and RS485, making them compatible with virtually all major industrial control systems (DCS, PLC, SCADA).

.png)